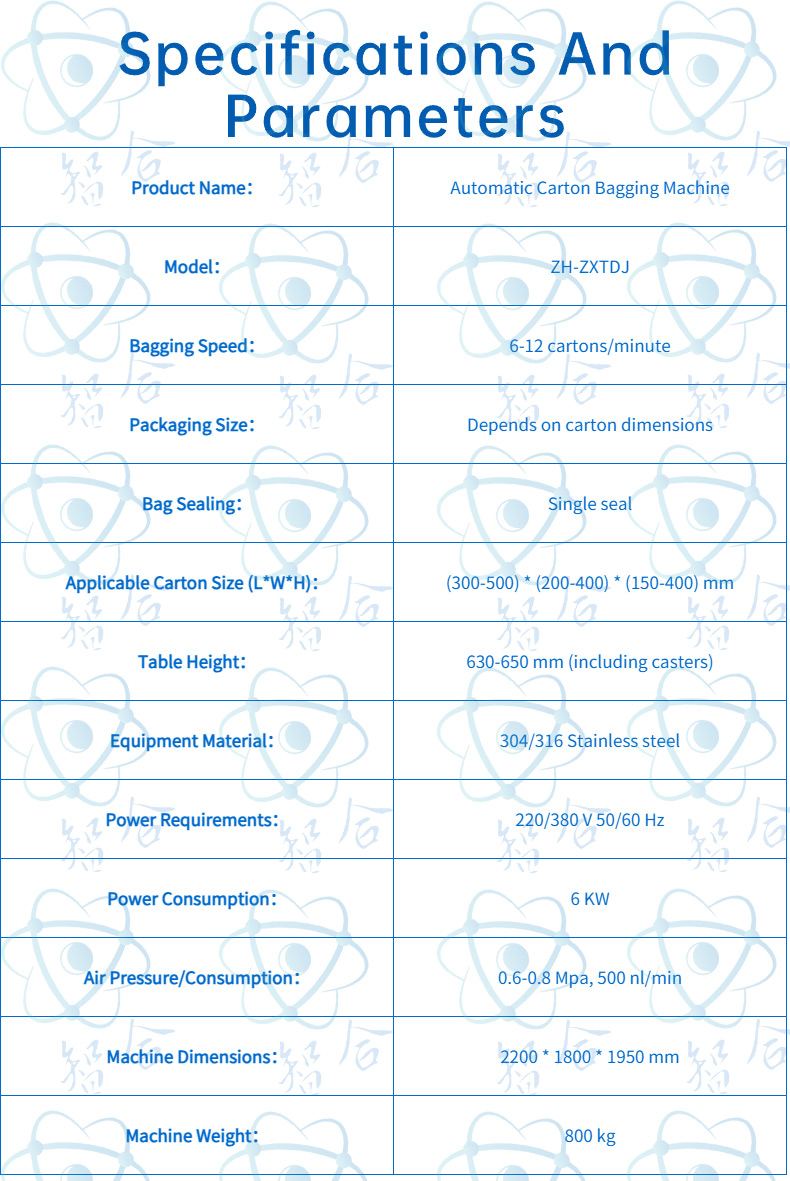

Fully Automatic Carton Bag Inserter Machine

Fully Automatic Carton Bag Inserter Machine

Fully Automatic Carton Bag Inserter Machines play a crucial role in modern automated packaging production lines. They efficiently and accurately complete the automatic bagging process for cartons, significantly improving production efficiency and reducing labor costs.

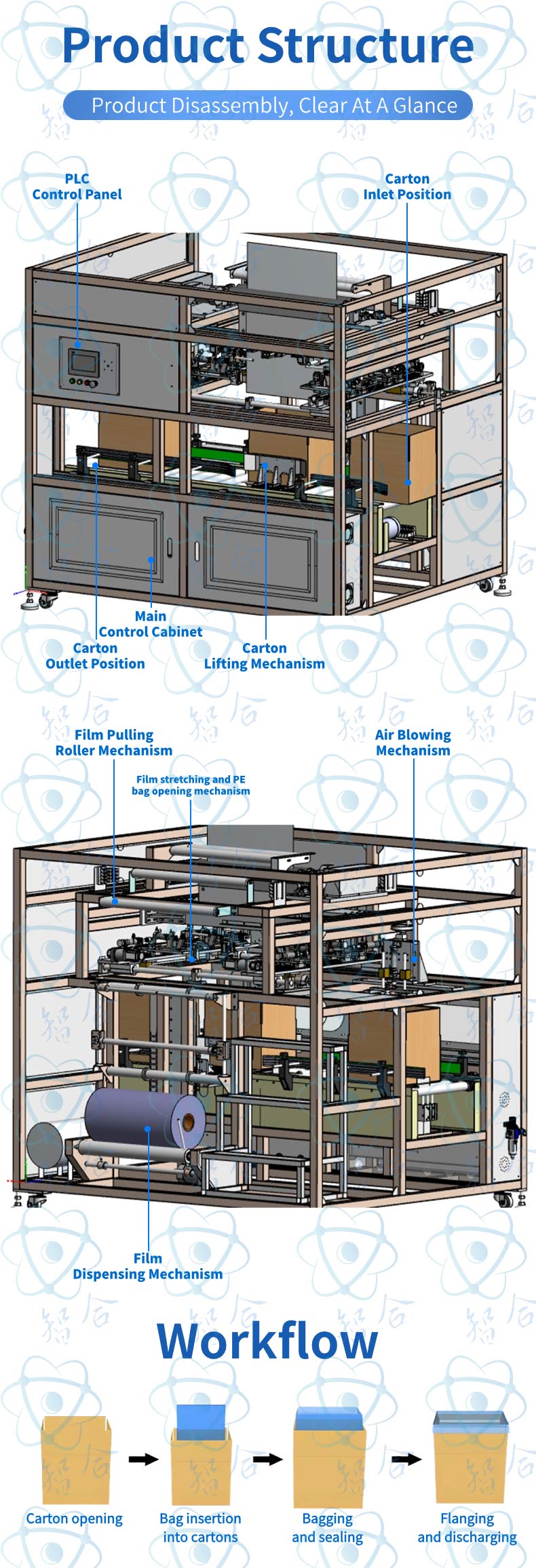

1. Equipment Overview and Functions

A fully Automatic Carton Bag Inserter Machine is a mechanical device that can automatically complete the carton bagging operation. Its core function is to automatically put pre-prepared plastic bags (usually PE bags or bags of other heat-sealable materials) inside or outside the carton, and seal them as needed, so as to achieve the purpose of protecting the items in the carton, moisture-proof, dust-proof and other purposes.

This kind of equipment is usually integrated into the automated packaging production line, and linked with carton forming machines, case packers, case sealers and other equipment to form a complete automated packaging system. It can be widely used in food, beverage, chemical, pharmaceutical, electronics, daily necessities and other industries, especially suitable for scenarios that require bag protection for products, such as:

Food industry: For example, rice, flour, pet food, granular food, powdered food, etc. bagging can effectively prevent food from moisture, deterioration, and prolong shelf life.

Chemical industry: For example, chemical raw materials, powdered chemicals, etc. bagging can prevent leakage, pollution, and ensure transportation safety.

Agricultural industry: For example, seeds, fertilizers, pesticides, etc. bagging can facilitate transportation and storage, and prevent scattering.

E-commerce logistics industry: For some products that need additional protection, bagging can be carried out before packing, which can improve the packaging strength and damage resistance.

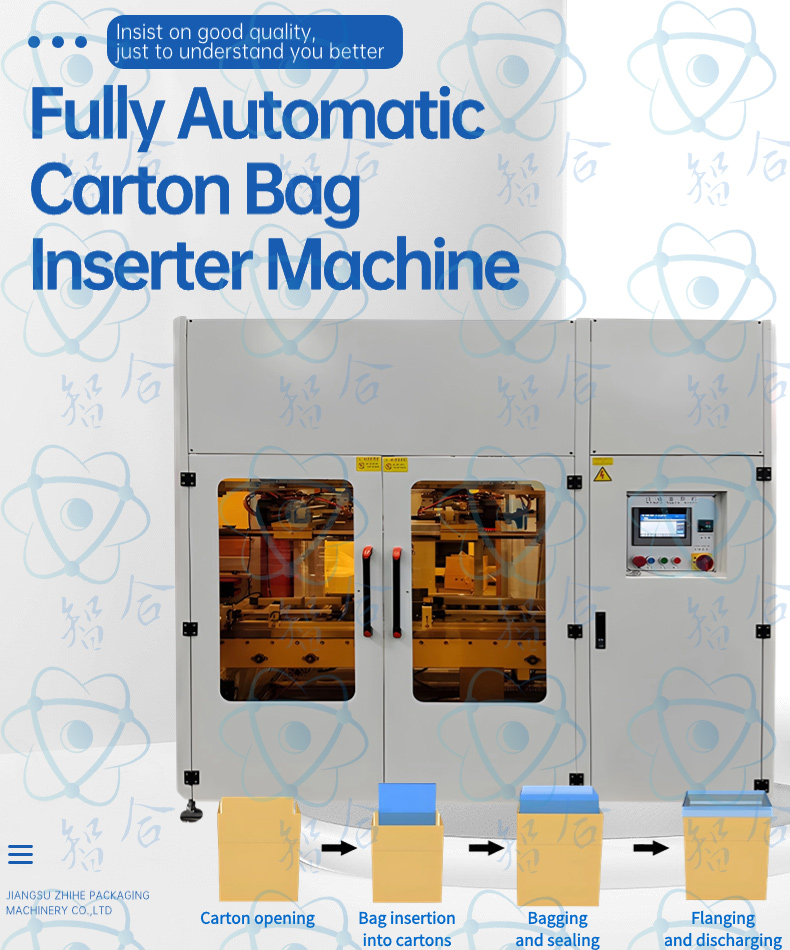

2. Working Principle and Process Detailed Explanation

The core of the fully Automatic Carton Bag Inserter Machine lies in its automated working process.

2.1 Carton Conveying and Positioning

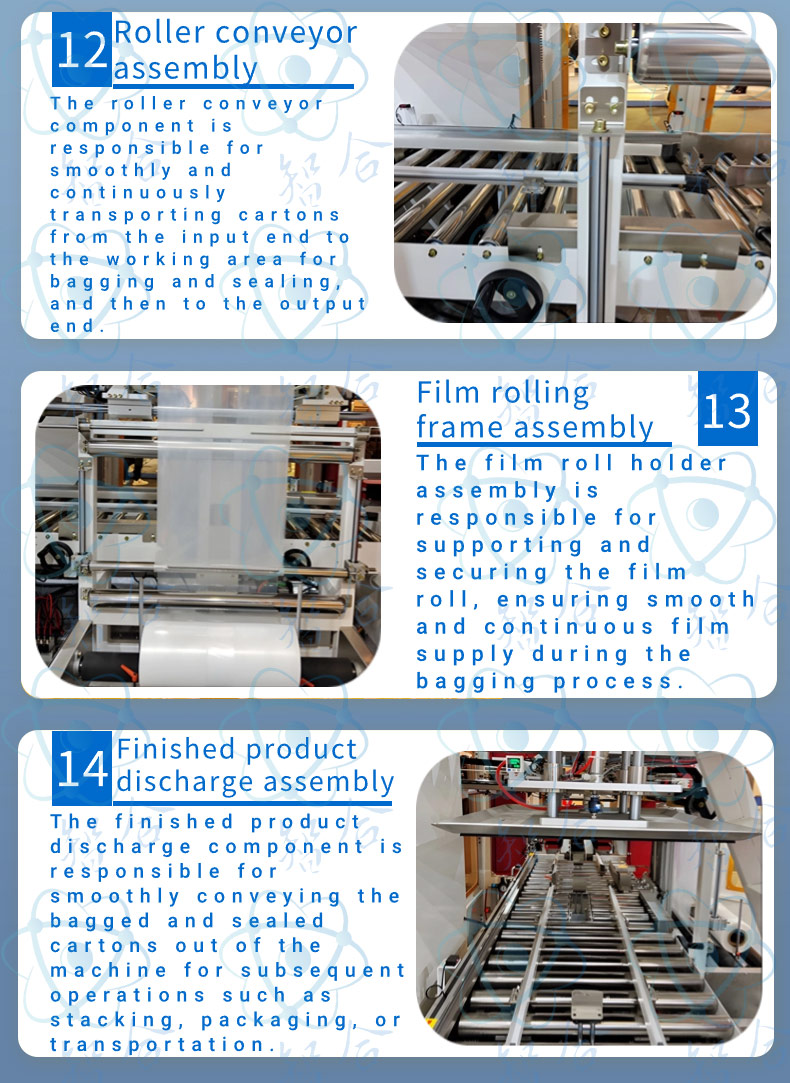

Carton supply system: Usually adopts belt conveyor, roller conveyor or vacuum suction cup grabbing to transport the cartons to be bagged to the bagging station.

Carton positioning mechanism: In order to ensure the accuracy of bagging, the equipment is equipped with a carton positioning mechanism. Common positioning methods include:

Baffle positioning: Use mechanical baffles or pneumatic baffles to position the carton laterally or front and rear.

Photoelectric sensor positioning: Use photoelectric sensors to detect the position of the carton, and feed the signal back to the control system to adjust the position of the carton.

Servo drive positioning: The positioning mechanism driven by the servo motor can achieve more accurate and faster carton position adjustment.

2.2 Bag Supply and Preparation

Bag roll holder and unwinding mechanism: The bagging machine usually uses roll film form of plastic bags. The bag roll is installed on the bag roll holder, and the unwinding mechanism is responsible for smoothly conveying the bag film. The unwinding mechanism is usually equipped with a tension control system to ensure that the bag film maintains constant tension during the conveying process and avoids slack or breakage.

Bag pre-opening mechanism: In order to facilitate the subsequent bag opening and bagging operations, the bag film needs to be pre-opened during the conveying process. Pre-opening methods include:

Vacuum suction cup adsorption opening: Use vacuum suction cups to adsorb both sides of the bag film and pull it open to form an opening.

Air blowing assisted opening: Use compressed air to blow the bag film to assist in opening it.

2.3 Bag Opening and Bagging

Bag opening mechanism: This is one of the most core components of the bagging machine, which is responsible for opening the pre-opened bag to form an opening that can be put into the carton.

Mechanical bag opening arm: Use the mechanical arm to extend into the bag and open the bag mouth outward. The bag opening arm is usually driven by a cylinder or a servo motor, which can precisely control the force and stroke of the bag opening.

Air blowing bag opening: Use compressed air to blow into the bag, and rely on air pressure to open the bag. The advantage of air blowing bag opening is that it has a simple structure and low cost, but the bag opening effect is slightly inferior to mechanical bag opening and vacuum suction cup bag opening.

Bagging mechanism: After the bag is opened, the bagging mechanism will accurately put the carton into the bag.

Vertical drop type bagging: The opened bag remains in a horizontal position, and the carton drops vertically from above, fitting into the bag. This method is suitable for cases where the carton size is relatively small.

Horizontal push type bagging: The carton moves horizontally to the front of the opened bag, and then the pushing mechanism pushes the carton horizontally into the bag. This method is suitable for cases where the carton size is relatively large.

3. Main Components

The fully Automatic Carton Bag Inserter Machine is a complex electromechanical integration equipment, mainly composed of the following core components:

Frame and body: As the skeleton of the equipment, it supports and fixes various functional modules. It is usually welded with high-strength steel to ensure the stability and durability of the equipment.

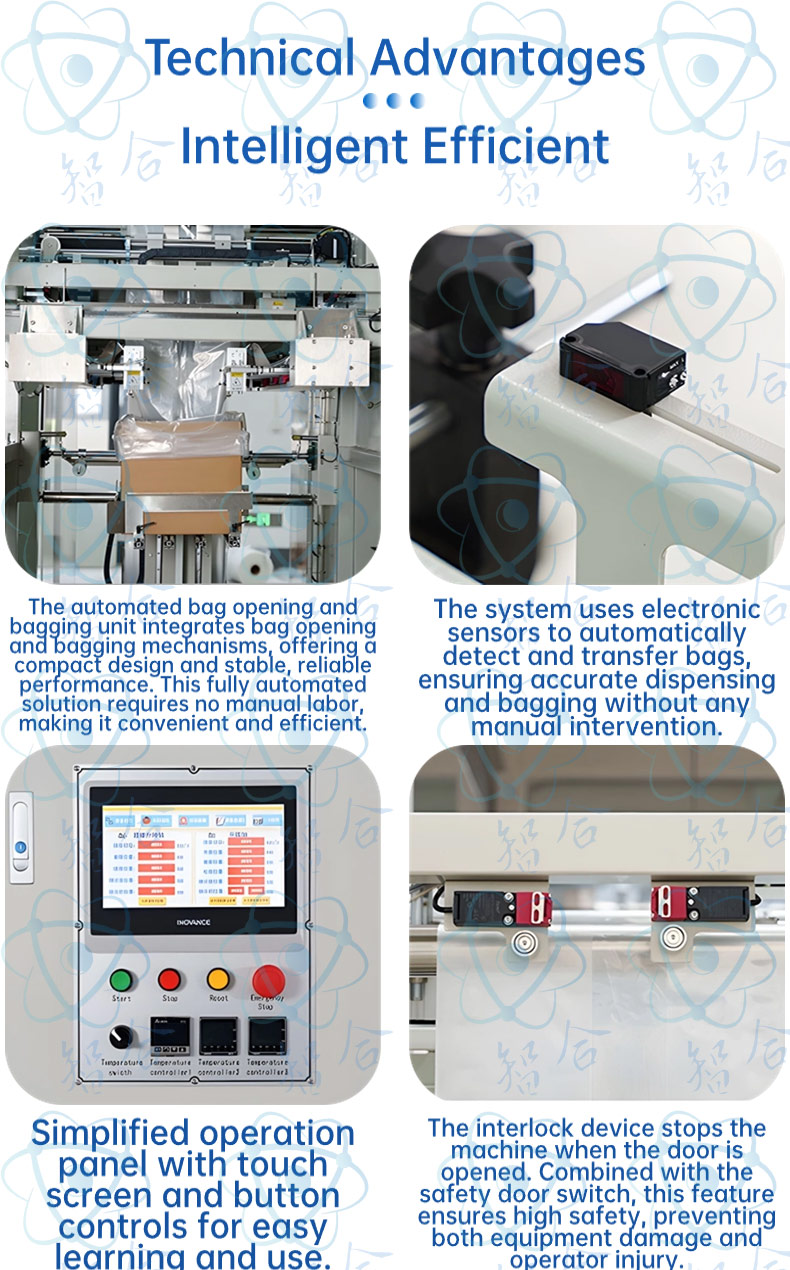

Control system: The “brain” of the equipment, responsible for controlling the coordinated operation of various actuators. Usually, PLC (programmable logic controller) is used as the main control unit, and the touch screen human-machine interface (HMI) is used for parameter setting, status monitoring and fault alarm.

Drive system: Provides power for various moving parts of the equipment. Mainly include:

Motor: Drive conveyor belts, bag opening mechanisms, bagging mechanisms, etc.

Cylinder: Drive baffles, clamping mechanisms, sealing mechanisms, etc.

Servo motor: Used in occasions requiring high precision and high response speed, such as carton positioning and fine control of the bag opening mechanism.

Sensor system: Used to detect the operating status of the equipment, the position of materials and other information, and feed the signal back to the control system.

Photoelectric sensor: Detect the position of cartons and bags.

Proximity switch: Detect the position of mechanical parts.

Pressure sensor: Detect the pressure of pneumatic and hydraulic systems.

Temperature sensor: Detect the temperature of the heat sealing mechanism.

Pneumatic system: Use compressed air as a power source to drive cylinders and other actuators. The pneumatic system has the advantages of simple structure, convenient maintenance and low cost.

4. Equipment Advantages and Features

Compared with the traditional manual bagging method, the fully Automatic Carton Bag Inserter Machine has significant advantages and features:

High degree of automation, saving labor: The equipment can automatically complete all processes such as carton conveying, bag preparation, bag opening, bagging, and sealing, which greatly reduces manual operation and reduces labor costs.

High efficiency and large capacity: The bagging speed is fast, which can realize high-speed continuous production, significantly improve packaging efficiency and capacity, and meet the needs of large-scale production.

Stable bagging quality and good consistency: The equipment adopts mechanized operation, with high bagging precision, smooth bag mouth and firm sealing, which ensures the stability and consistency of packaging quality and improves the beauty and grade of product packaging.

Reduce material waste: The equipment can accurately control the length and dosage of the bag, avoiding the situation that the bag may be too large or too small in manual bagging, and reducing material waste.

Simple operation and convenient maintenance: Modern fully automatic bagging machines usually adopt human-machine interface operation, the parameter setting is simple and intuitive, and the fault diagnosis and troubleshooting are convenient and fast. The equipment has a reasonable structure design, which is convenient for daily maintenance.

Strong adaptability and wide application: The equipment can adapt to cartons of different sizes and shapes, and bags of different materials and specifications by adjusting parameters and replacing molds, and has a wide range of applications.

Summary

As an important part of the modern automated packaging production line, the fully Automatic Carton Bag Inserter Machine, with its high-efficiency, stable and reliable performance, greatly improves the packaging efficiency and product packaging quality, saves labor costs for enterprises, and improves market competitiveness. In-depth understanding of its technical details will help users better select, use and maintain the equipment, so as to give full play to its effectiveness and create greater value for enterprises.