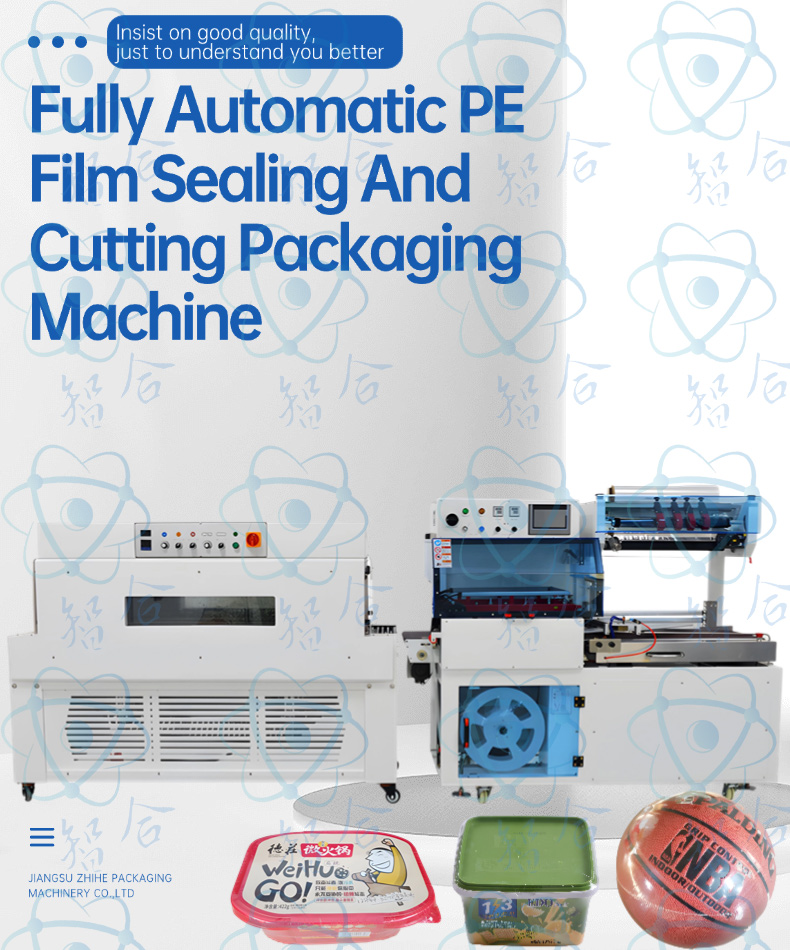

The Fully Automatic PE Film Sealing and Cutting Packaging Machine is a highly automated, unmanned edge-sealing packaging equipment specifically designed to enhance packaging efficiency and quality. Below is a detailed description of its technical characteristics and working principles:

The Fully Automatic PE Film Sealing and Cutting Packaging Machine is a highly automated, unmanned edge-sealing packaging equipment specifically designed to enhance packaging efficiency and quality. Below is a detailed description of its technical characteristics and working principles:

Technical Characteristics and Working Principles in Detail

- Fully Automatic Operation Process and Flexibility

- Fully Automatic Operation: From product loading, the Fully Automatic PE Film Sealing and Cutting Packaging Machine can automatically complete the entire packaging process, including conveying, positioning, sealing, and shrinking. This highly automated process reduces manual intervention and improves production efficiency.

- Versatile Adaptability: By adjusting machine settings, this equipment can handle products of different heights, widths, and shapes. For example, adjusting the speed and position of the conveyor belt can accommodate various product sizes; adjusting the position and angle of the sealing blade ensures that the sealing line is always centered on the product.

- Advanced Sealing and Cutting Technology

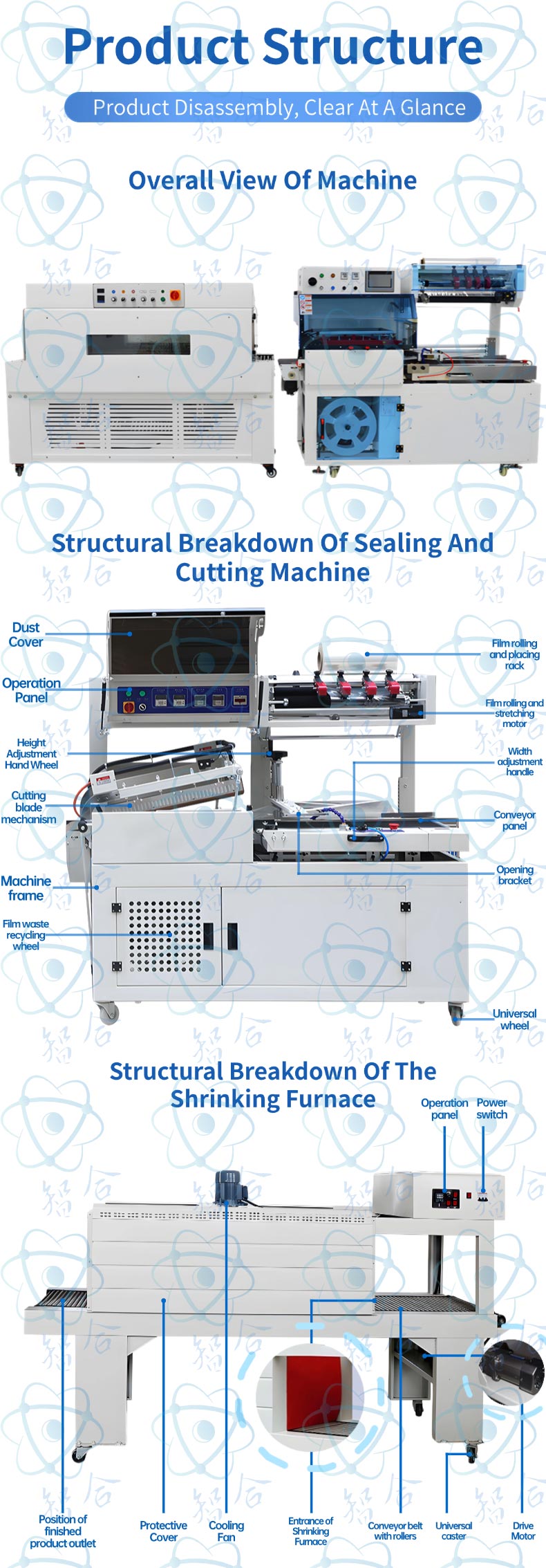

- Horizontal and Vertical Blade Design: The horizontal blade uses vertical drive to ensure a straight and secure sealing line. The vertical blade employs constant temperature side sealing technology, with a precise temperature control system maintaining a constant blade temperature, thus ensuring the quality and consistency of the sealing line.

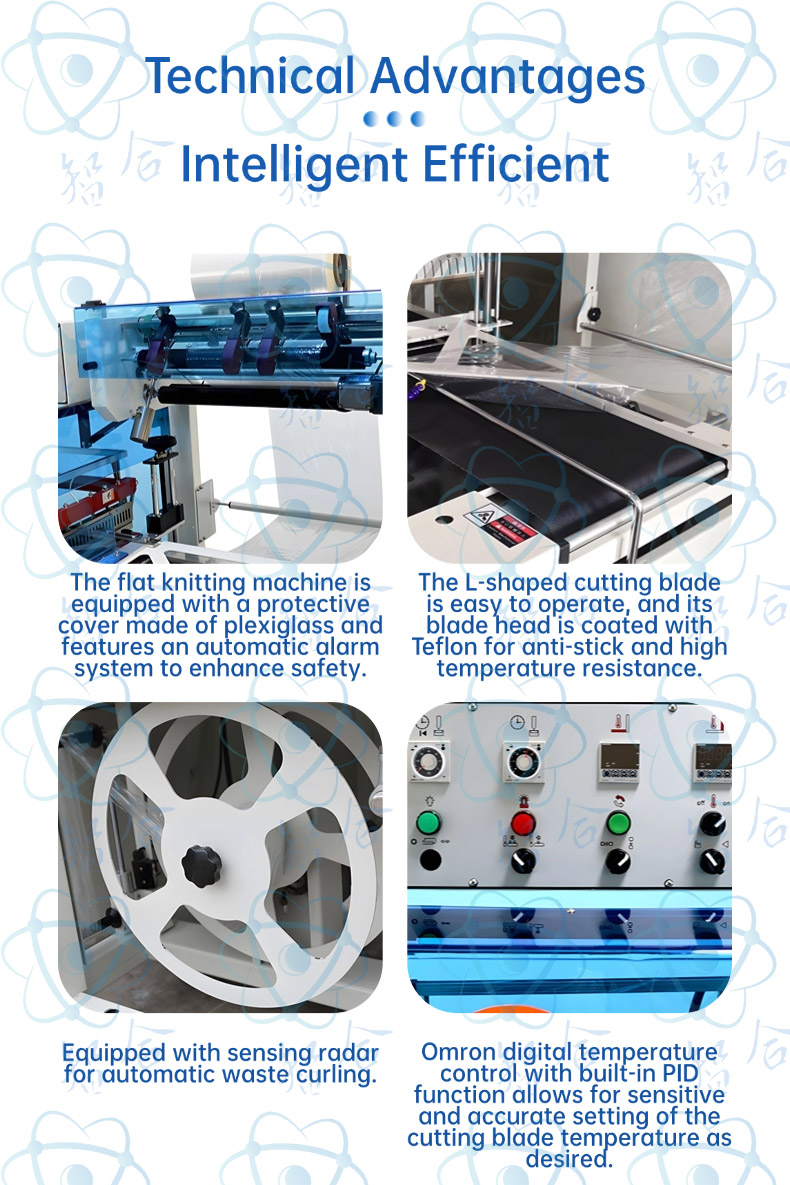

- Constant Temperature Heating and Sealing System: This system automatically adjusts the temperature and pressure of the sealing blade according to the type and thickness of the packaging material. This feature not only enhances the sealing strength but also reduces damage to packaging materials due to improper temperature.

- Easily Adjustable Sealing and Cutting System: Users can easily adjust the parameters of the sealing and cutting system through adjustment devices such as handwheels, adapting to various packaging material specifications and types. This flexibility allows the equipment to handle multiple packaging needs.

- Precise Feeding and Positioning Control

- Combination of Electric Eye Detection and Timer: Feeding length is precisely controlled through a combination of electric eye detection and a timer. The electric eye monitors the position and length of the packaging material, while the timer controls feeding speed and time. This combination ensures precise conveying and positioning of the packaging material.

- Horizontal and Vertical Electric Eyes: Equipped with two sets of horizontal and vertical electric eyes, allowing switching based on the shape and size of the packaged item. This design enables the equipment to handle various shapes and sizes of packaged goods, including thin and small items.

- Automatic Waste Handling and Eco-Friendly Design

- Automatic Waste Winding: Waste is collected and processed through an automatic winding device. This feature reduces the time and cost of manual waste handling, enhancing machine neatness and work efficiency.

- Eco-Friendly Design: The equipment emphasizes eco-friendly concepts in design and manufacturing, using energy-efficient motors and control systems to reduce energy consumption and carbon emissions. Meanwhile, precise control of the sealing blade’s temperature and pressure reduces packaging material waste and damage.

- Customizable Configurations and Extended Functions

- Automatic Blowing Function: An automatic blowing function can be added based on customer needs, used to expel air from within the packaging material before sealing, resulting in a more compact and aesthetically pleasing package.

- Front Power Feeding Line and Rear Storage Platform: Optional front power feeding line and rear non-powered storage platform to adapt to different production environments and packaging needs. These configurations not only improve production efficiency but also facilitate product storage and transportation.

Working Principles in Detail

- Product Loading and Conveying: Products are conveyed smoothly to the designated position by the conveyor belt, either through the front power feeding line (if equipped) or manually placed inside the machine. The speed and position of the conveyor belt can be adjusted according to product size and shape.

- Positioning and Packaging Material Conveying: Through precise sensors and control systems, the product is accurately positioned on the packaging material. Simultaneously, the packaging material is conveyed to the sealing position by the feeding device.

- Sealing and Cutting: The horizontal and vertical blades work simultaneously to seal and cut the packaging material. The constant temperature heating system ensures a constant blade temperature, thereby ensuring the quality and consistency of the sealing line. After cutting, waste is collected and processed through the automatic winding device.

- Shrinking and Output: After sealing and cutting, the packaging material undergoes shrinking treatment through a heat shrinking tunnel. During this process, the packaging material is heated and tightly adheres to the product surface, creating a compact and aesthetically pleasing packaging effect. Finally, the packaged product is temporarily stored on the rear storage platform (if equipped) or directly output to the next process.

The Fully Automatic PE Film Sealing and Cutting Packaging Machine, with its high automation, precise sealing and cutting technology, flexible feeding and positioning control, automatic waste handling, and customizable configurations, has become a crucial piece of equipment in the modern packaging industry. These features not only improve production efficiency and quality but also reduce labor costs and energy consumption, providing strong support for enterprises’ sustainable development.