Product Overview:

Product Overview:

The fully automatic blister packaging machine is a packaging equipment specifically designed for the pharmaceutical, healthcare, food, electronics, hardware, and other industries. It efficiently and accurately completes the packaging of block-shaped object (bulk materials), granular particles, and liquids. The machine supports various colored sheet materials such as PVC, PS, PET, and enhances the aesthetic appeal and protective performance of products through blister packaging forms such as aluminum-plastic, aluminum-aluminum, and paper-plastic.

Technical Features

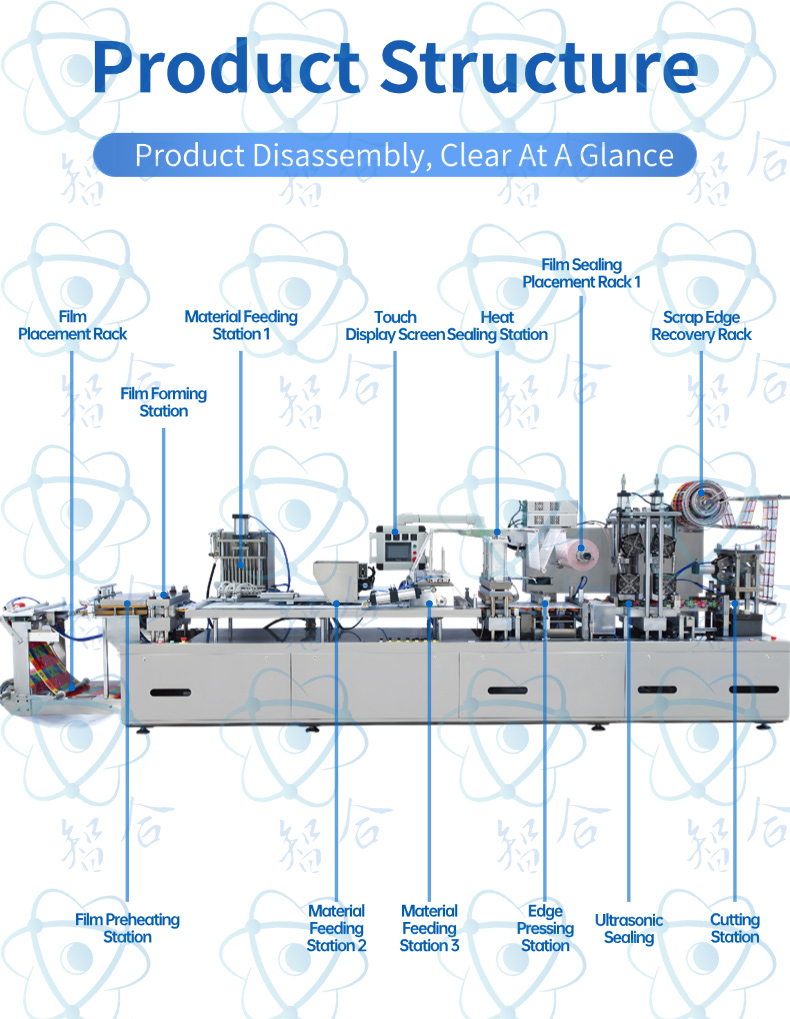

Modular Design:

Key devices such as molding, heat sealing, batch number printing, creasing, and punching adopt a modular design for easy disassembly and replacement.

Each device is positioned using a spline shaft with gear racks. By turning the handle, devices can be easily moved and precisely calibrated and positioned using scales and tightening nuts.

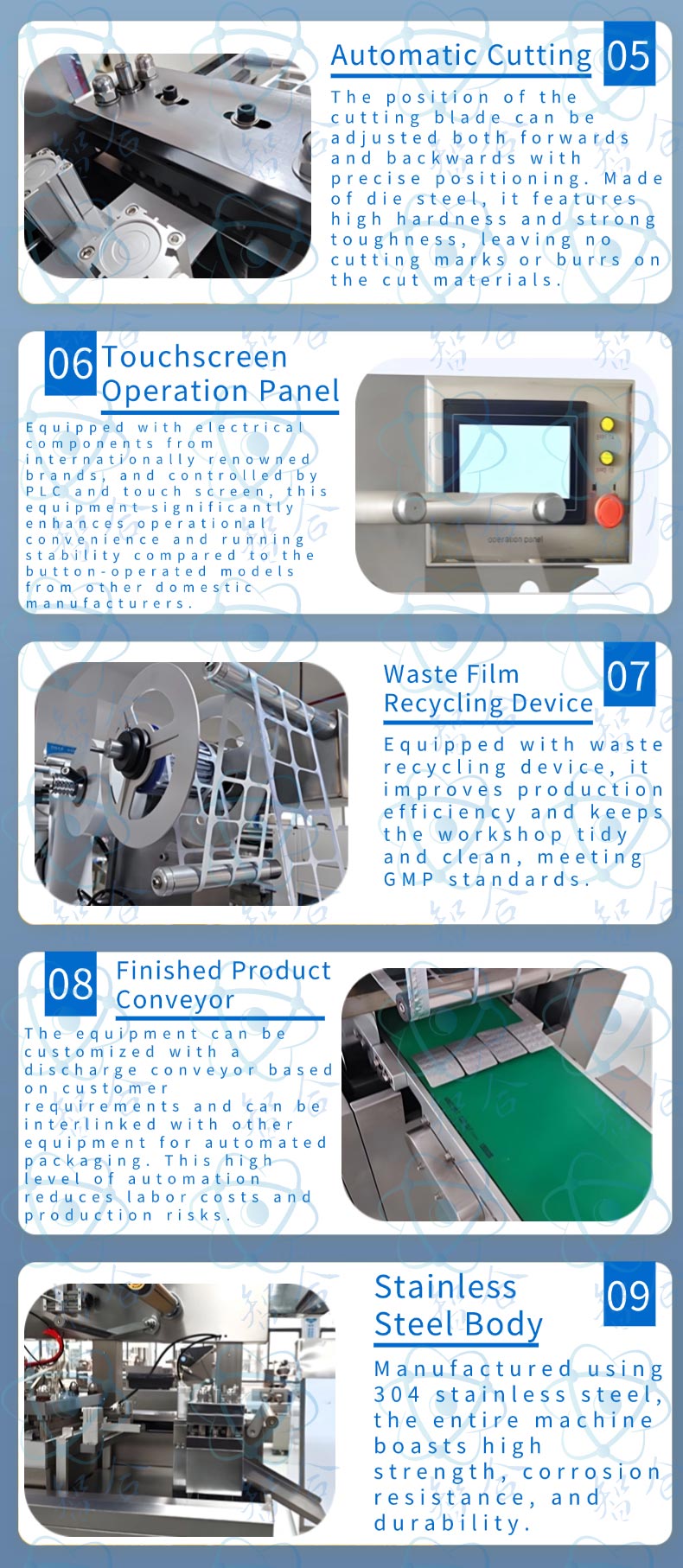

Advanced Control System:

PLC control with a user-friendly human-machine interface for easy operation.

Variable frequency speed adjustment allows adjusting the packaging speed according to production needs for efficient production.

Fault display and automatic alarm system for timely identification and resolution of issues, ensuring stable production processes.

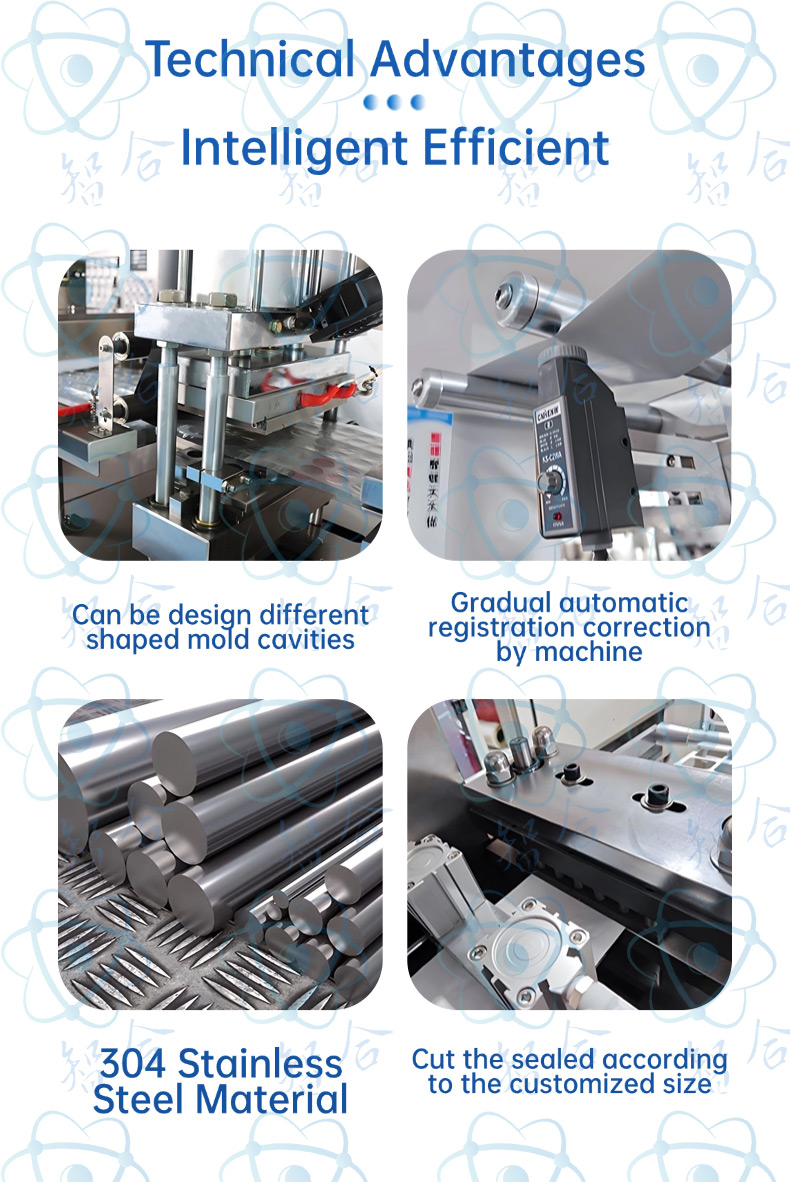

High-Precision Molds:

Molds for molding, heat sealing, and creasing use dowel pins for positioning and are secured with pressure plates to ensure accurate positioning and easy mold changing.

The mold design is reasonable, saving packaging materials and reducing production costs.

Automated Workflow:

Color sheet material alignment and molding → filling (optional) → sealing → batch number printing → punching → finished product output. The entire process is automated, reducing manual intervention and improving production efficiency.

Stable and Reliable Operation:

The main drive uses a parallel-axis helical gear reducer for smooth operation and low noise.

The machine design complies with GMP requirements, ensuring cleanliness of the production environment and product safety.

Working Principle

The working principle of the fully automatic blister packaging machine mainly includes the following steps:

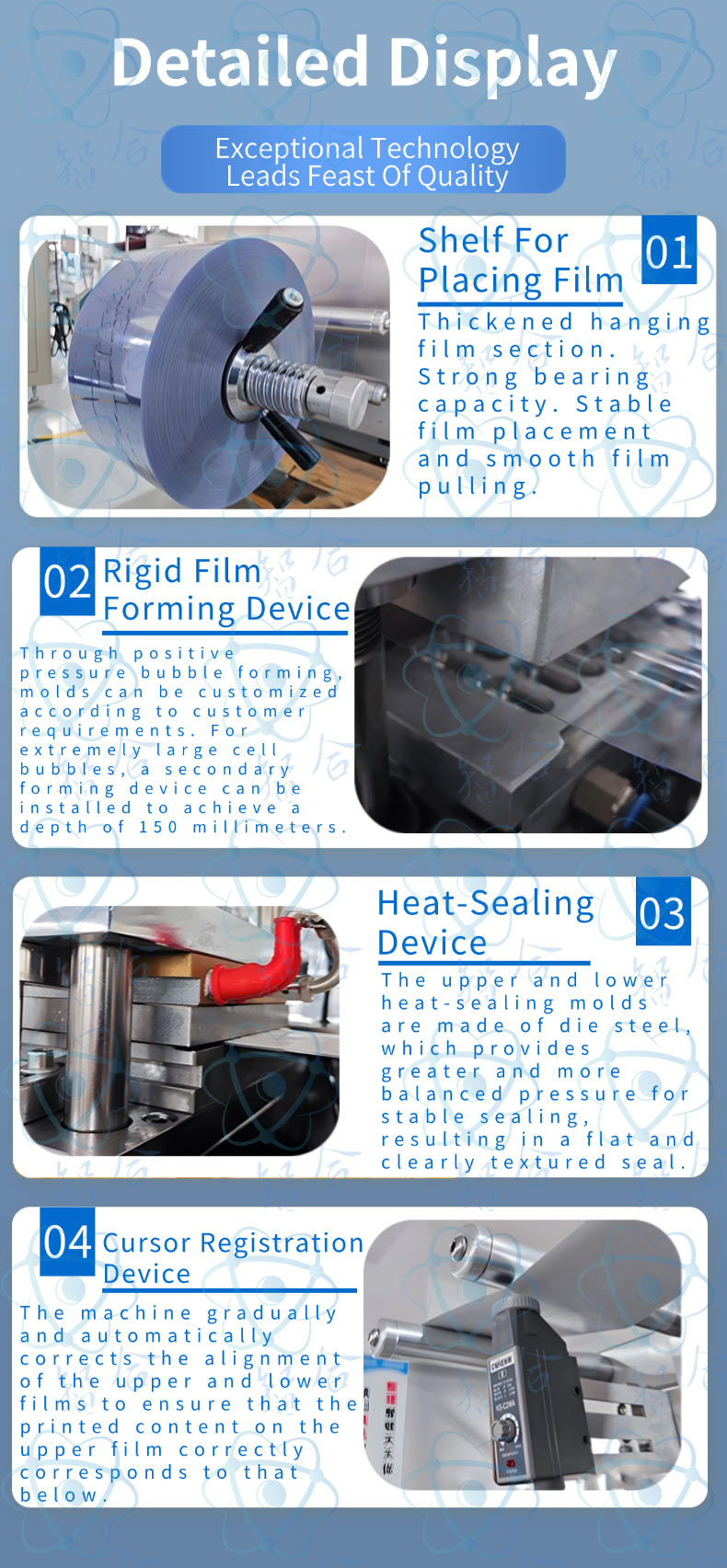

Sheet Material Molding:

The colored sheet material is fed into the molding mold and formed into a blister shape through heating and pressure.

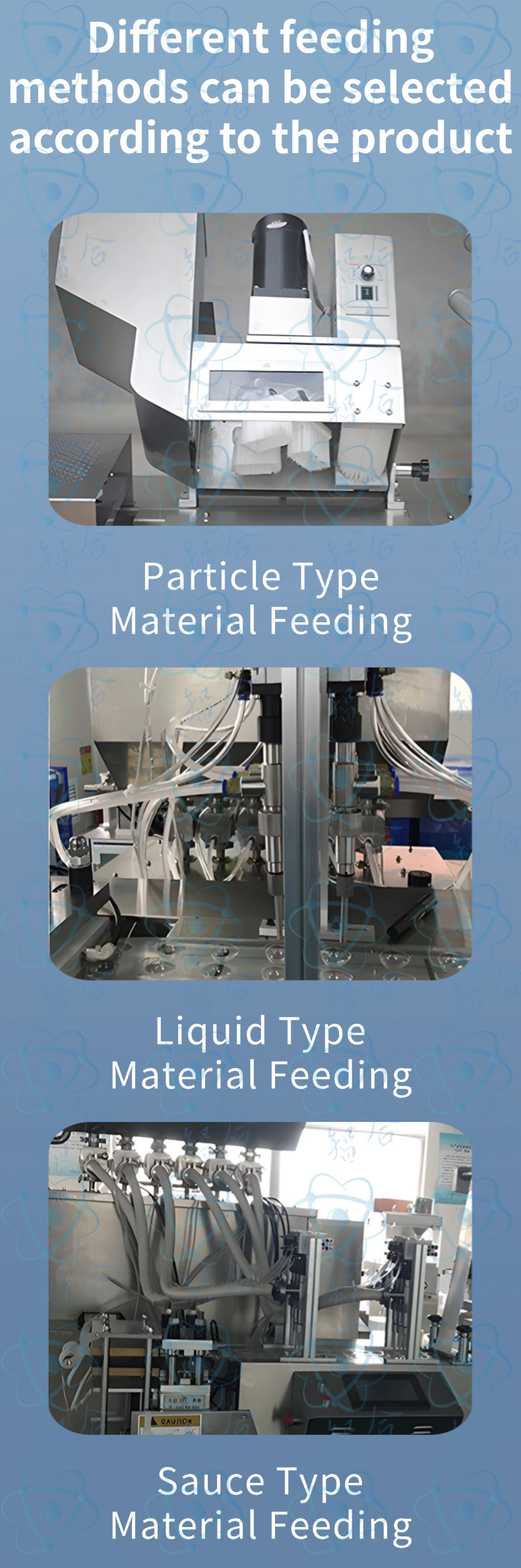

Filling (Optional):

For products that require filling, the filling device fills bulk materials, granular particles, or liquids into the blisters.

Sealing:

The upper and lower materials of the blister are heat-sealed together using a heat-sealing device to form a sealed package.

Batch Number Printing:

The production batch number or relevant information is printed on the sealed package for traceability.

Punching:

The sealed package is separated from the sheet material using a punching device to form independent finished products.

Finished Product Output:

The finished products are conveyed to a collection device or conveyor belt, completing the entire packaging process.

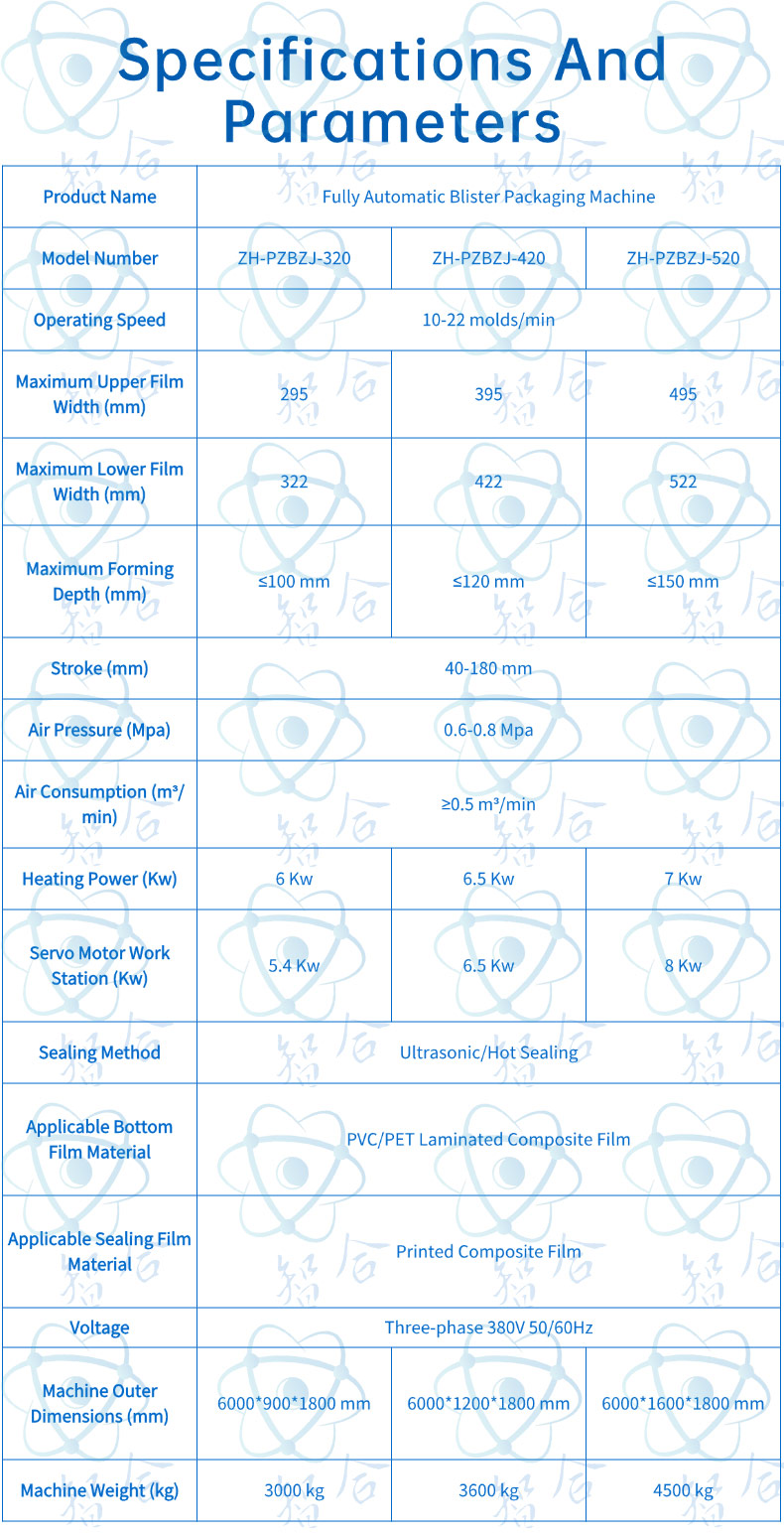

Product Parameters

- Sealing and Cutting Speed (cycles/min): 6-44

- Maximum Molding Area and Depth (mm): 320×150×25

- Stroke Range (mm): 40-160

- Air Pressure (MPa): 0.4-0.7

- Air Flow Rate: ≥0.35m³/min

- Total Power Supply: 380V/50Hz / 5.5kw

- Main Motor Power (kW): 1.5kw

- Electric Control System: Inovance (Shenzhen)

- Mold Cooling: Tap water or circulating water

- Pharmaceutical PVC Sheet (mm): 0.25-0.5×340

- PTP Aluminum Foil (mm): 0.02-0.035×340

- Overall Dimensions (mm): 5400×670×1880

- Total Machine Weight (KG): 1350

Scope of Application

The fully automatic blister packaging machine is particularly suitable for the following industries and products:

- Pharmaceutical Industry: Tablets, capsules, etc.

- Healthcare Industry: Soft capsules, hard capsules, granular preparations, etc.

- Food Industry: Candies, milk tablets, chocolates, etc.

- Electronics Industry: Small electronic components, batteries, etc.

- Hardware Industry: Small hardware parts, screws, etc.

In summary, with its efficient, precise, and stable performance, the fully automatic blister packaging machine has become an indispensable packaging equipment for numerous industries.