Fully Automatic High-Speed Over-Wrapping Packaging Machine Detailed Description

Fully Automatic High-Speed Over-Wrapping Packaging Machine Detailed Description

Product Overview

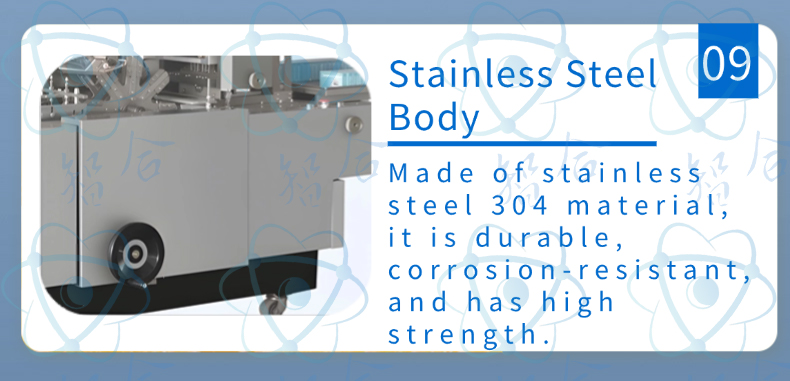

The Fully Automatic High-Speed Over-Wrapping Packaging Machine is an automated packaging equipment that integrates high technology with practicality. It is widely used in various industries such as food, beverages, daily chemicals, medical, pharmaceuticals, pesticides, and more. It can efficiently complete the film packaging of various products such as playing cards, health supplements, pharmaceuticals, cosmetics, erasers, tea, chewing gum, daily necessities, stationery, and more. Products packaged through this equipment not only have functions of anti-counterfeiting, moisture-proof, and dust-proof, but also significantly enhance the product’s grade, added value, and appearance quality.

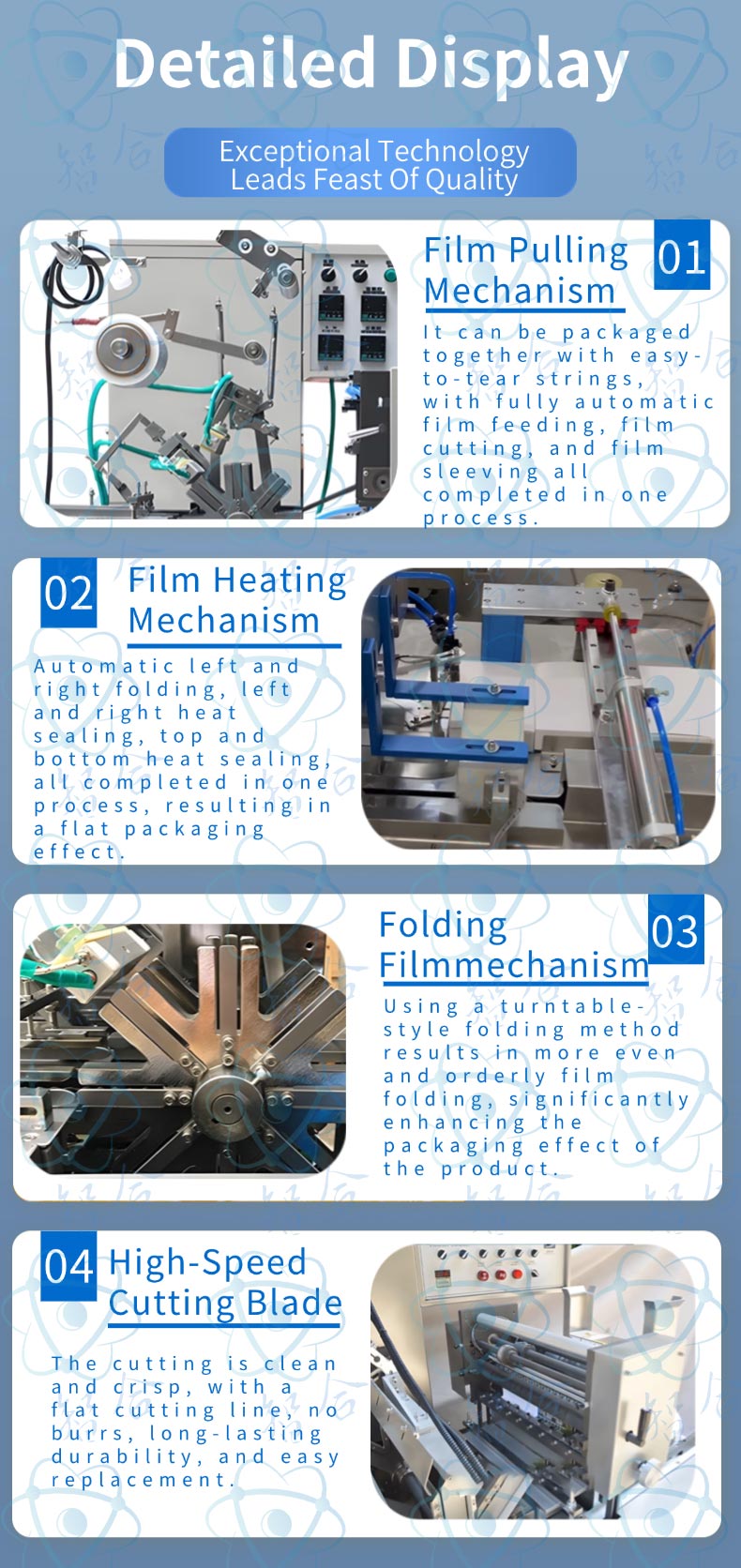

Technical Features

- Advanced Control System: The machine adopts imported PLC as the control center, achieving efficient operation of electromechanical integration. The PLC system boasts flexible programming, high reliability, strong anti-interference ability, and other advantages, ensuring stable operation and precise control of the equipment.

- Multi-Station Turntable Alternating Packaging: The equipment adopts a multi-station turntable design, with each station alternately performing wrapping, heat sealing, and other actions, greatly improving packaging efficiency. Meanwhile, the cam transmission mechanism ensures fast, stable, and accurate performance of all actions.

- Convenient Mold Replacement: The machine adopts a newly designed multi-patent structure, making mold replacement simpler and faster. Users only need to replace the corresponding mold to easily adapt to the packaging needs of different-sized items.

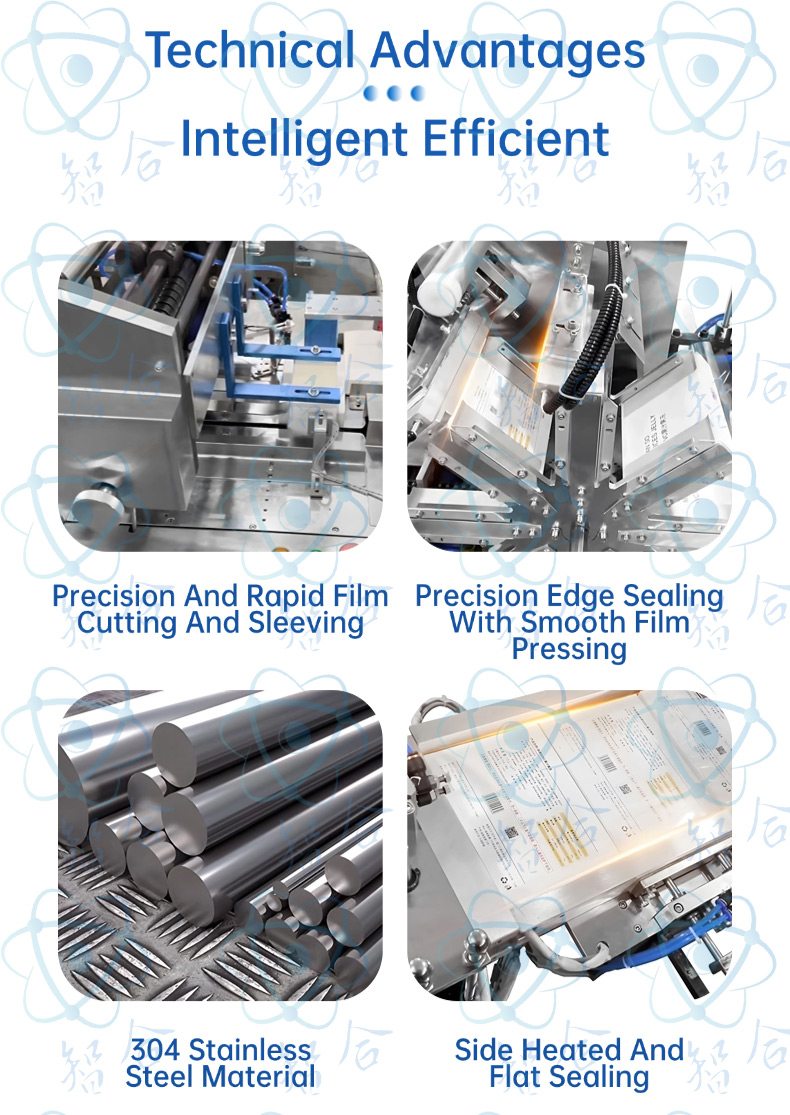

- New Single-Rotating Film Cutting Blade: The equipment is equipped with a new single-rotating film cutting blade, which is characterized by high precision and smooth film cutting. Regardless of product size, there is no need to replace the film cutting mechanism, greatly saving users’ operation time and cost.

- Upper and Lower Double-Layer Blowing Auxiliary Film Device: To eliminate static electricity on the packaging film, the machine is specially designed with an upper and lower double-layer blowing auxiliary film device. This device, through blowing action, makes the film feeding process smoother, avoiding film feeding difficulties caused by static electricity.

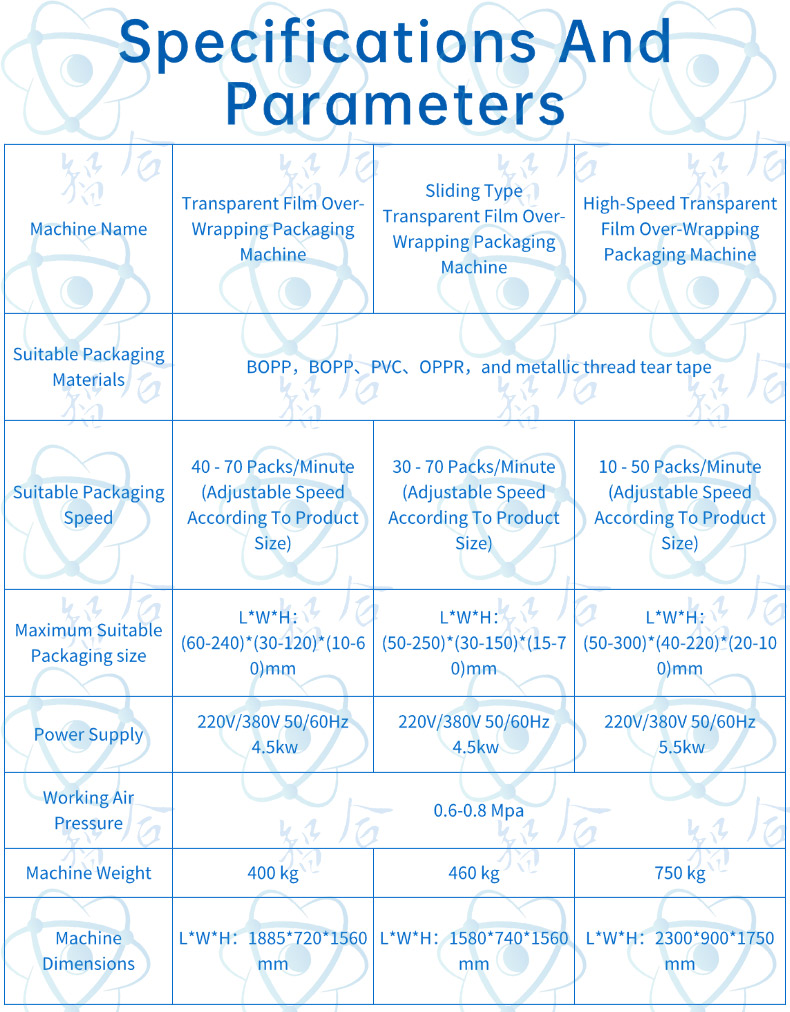

- Frequency Converter Adjusts Packaging Speed: The equipment uses a frequency converter to adjust the packaging speed, allowing users to freely adjust within the range of 40 to 80 packs per minute based on actual needs. This design not only improves the flexibility of the equipment but also meets the needs of different production scenarios.

- Double-Sided Crease Cosmetic Device: The machine is equipped with a double-sided crease cosmetic device, which can shape and beautify the packaging film, making the packaging more fitting and aesthetically pleasing.

- Composite Adhesive Laser Anti-Counterfeiting Tear Line Function: The equipment can be optionally equipped with a composite adhesive laser anti-counterfeiting tear line function. This function uses laser technology to print anti-counterfeiting marks and tear lines on the packaging film, effectively improving the product’s anti-counterfeiting performance and moisture-proof effect.

Working Principle

The working principle of the Fully Automatic High-Speed Over-Wrapping Packaging Machine is as follows:

- Feeding Stage: Users place the products to be packaged on the feeding device, which conveys the products to the packaging station through a conveyor belt or robotic arm.

- Wrapping Stage: When the product reaches the packaging station, the packaging film is pulled from the film roll and wrapped around the product. At this time, the upper and lower double-layer blowing auxiliary film device begins to work, eliminating static electricity on the packaging film and making it fit the product more snugly.

- Heat Sealing Stage: After wrapping, the heat sealing mechanism heats and presses the packaging film to form a sealed packaging structure. The heat sealing temperature and pressure can be adjusted according to actual needs to ensure sealing effectiveness.

- Shaping and Cosmetic Stage: The packaged products, after heat sealing, pass through the double-sided crease cosmetic device for shaping and beautification, making the packaging smoother and more aesthetically pleasing.

- Output Stage: The packaged products, after shaping and beautification, are conveyed to a designated location through a conveyor belt or robotic arm for subsequent processing or warehousing.

Other Functions

- Double Safety Mechanism: The machine adopts a double safety mechanism design. When the machine operates asynchronously, there is no need to stop it, and it will not damage other components. This design greatly improves the reliability and safety of the equipment.

- Hand Crank Device: The equipment is equipped with a hand crank device, allowing users to clear jammed products or make other necessary adjustments by turning the machine forward or backward.

- Convenient Height Adjustment: When changing molds, there is no need to adjust the height of the working tables on both sides of the machine. When adjusting the film cutting mechanism and upper shaping, simply turn the handwheel to change the height, without needing to dismantle and assemble the discharge chain and feeding hopper.

- Automated Unattended Production Line Connection: By changing the feeding method, the machine can easily connect with fully automated unattended production lines, achieving automation and intelligent upgrading of the production line.

In summary, the Fully Automatic High-Speed Over-Wrapping Packaging Machine, with its advanced technical features, efficient working principle, and rich functional configuration, has become a leader in the field of automated packaging across various industries.