Detailed Description of Fully Automatic Tube Filling and Sealing Machine (Model ZHGZFWJ-60)

Detailed Description of Fully Automatic Tube Filling and Sealing Machine (Model ZHGZFWJ-60)

- Equipment Overview

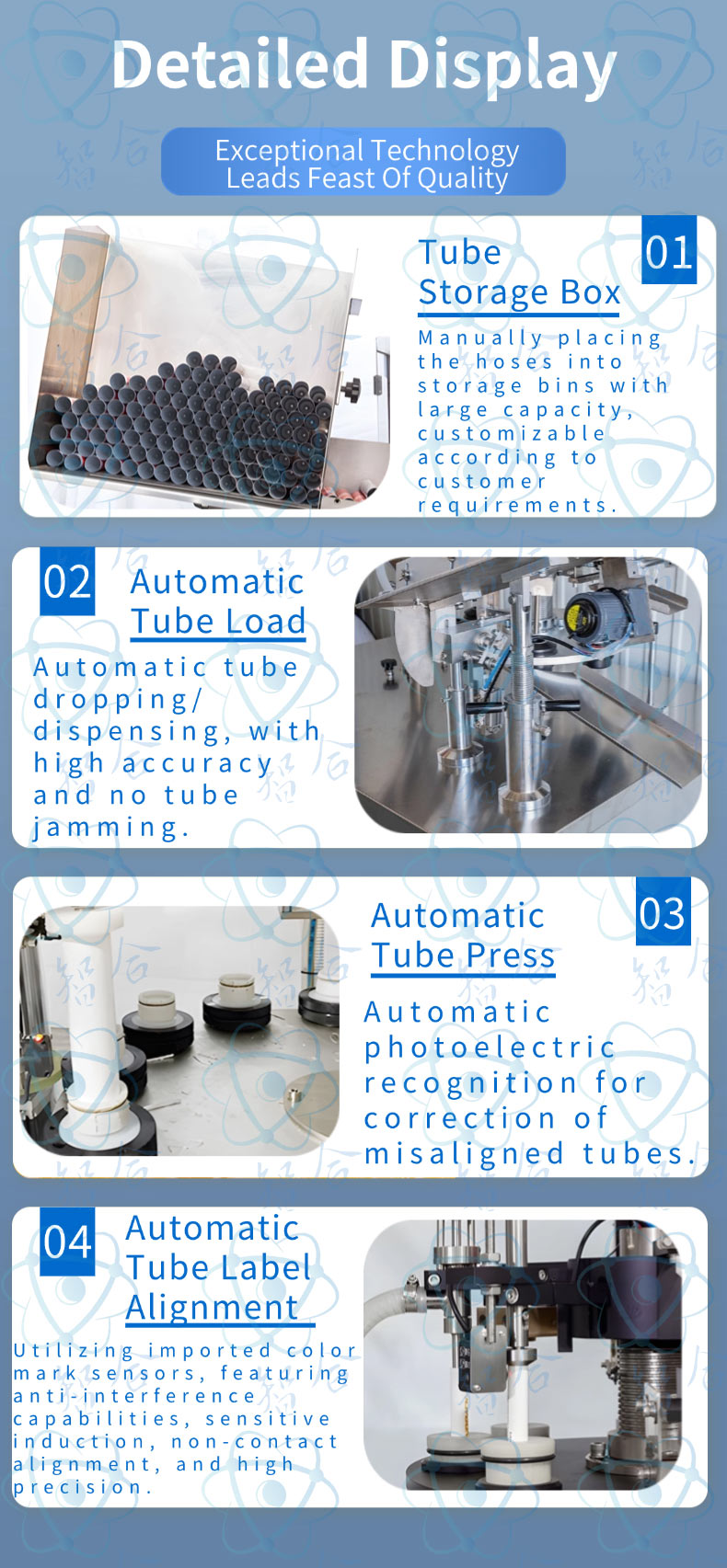

The ZHGZFWJ-60 automatic tube filling and sealing machine is a highly efficient production equipment specifically designed for industries such as toothpaste, cosmetics, pharmaceuticals, and food. This machine integrates multiple functions including filling, sealing, batch number printing, and automatic tube ejection. With its high degree of automation and precise process control, it has become a preferred choice for numerous production lines. - Technical Features

- High Automation: From automatic color mark alignment, filling, sealing, batch number printing, to automatic tube ejection, the entire process requires no manual intervention, significantly improving production efficiency and product consistency.

- Precise Alignment: Utilizing a photoelectric color mark alignment station equipped with high-precision probes and stepper motors, it ensures that the tube patterns are always in the optimal position, meeting the aesthetic and accuracy requirements of packaging.

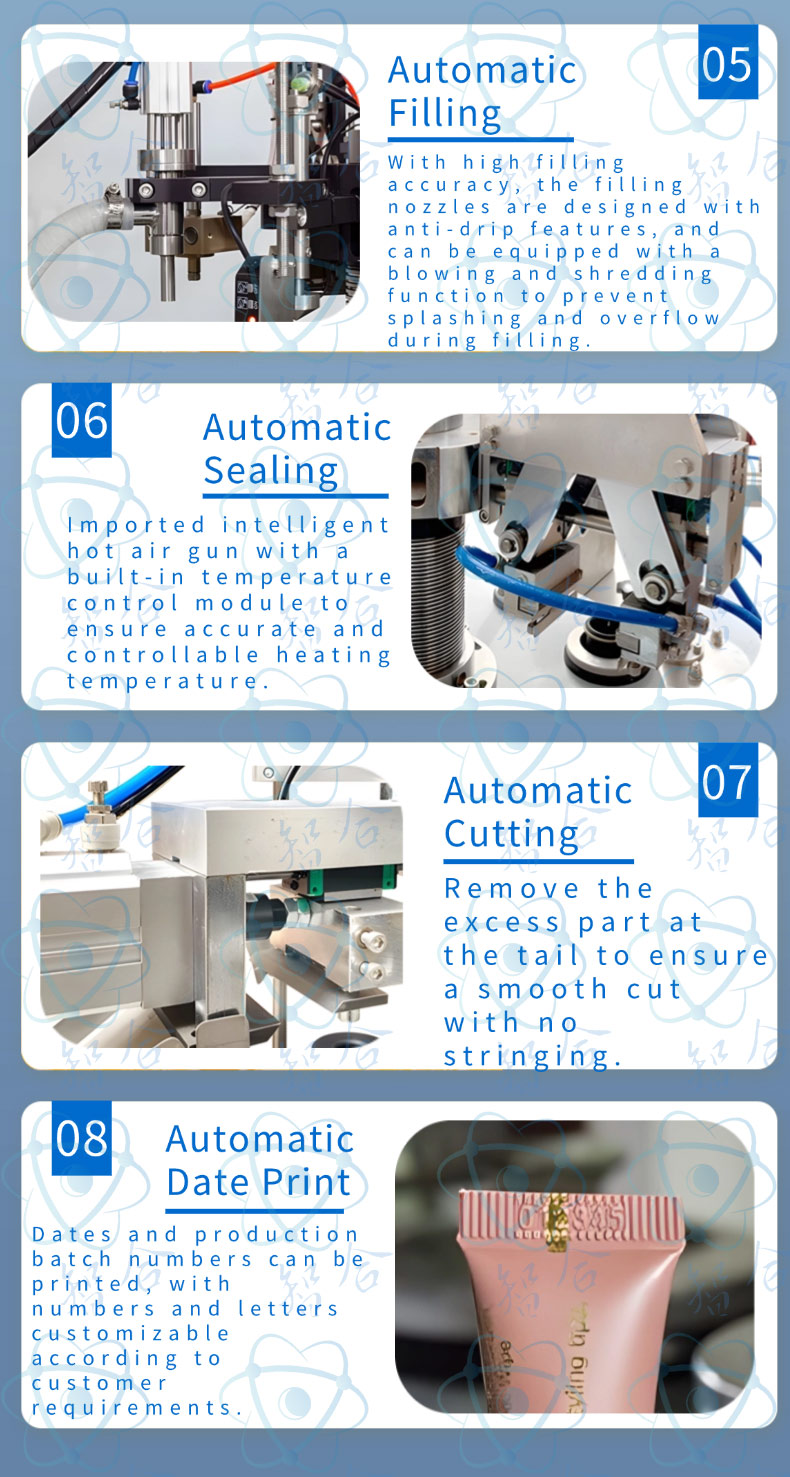

- Advanced Heating Technology: Adopting an internal heating method in conjunction with a “LEISTER” hot air blower from Switzerland, hot air is blown from the inside of the tube to achieve rapid melting of the plastic. This ensures sealing quality while reducing external heat impact, thereby protecting the tube’s appearance.

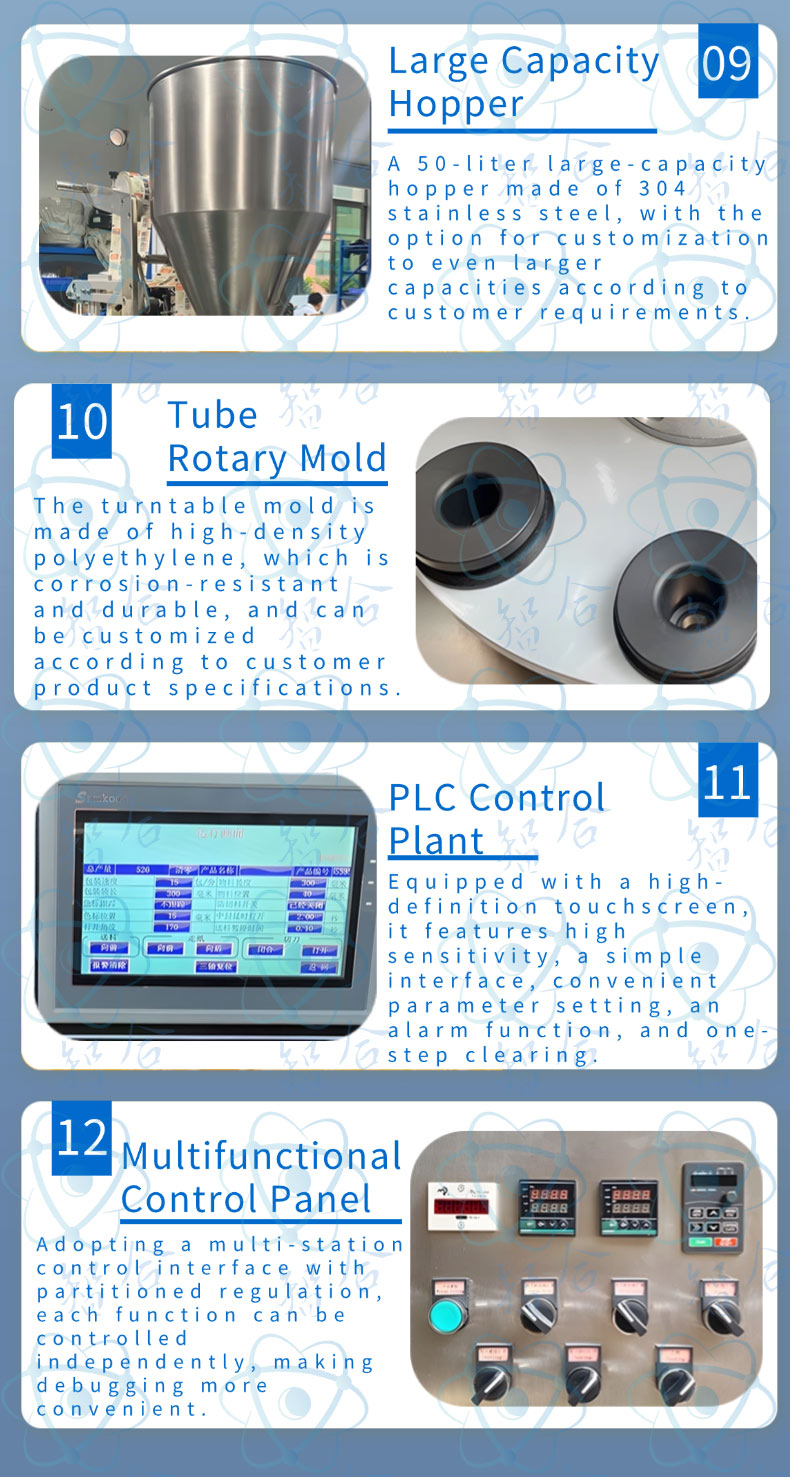

- Precise Control: The indexing mechanism uses a precision cam indexing mechanism to ensure accurate and stable positioning. The indexing motor employs frequency conversion speed regulation technology, allowing users to flexibly adjust the operating speed according to production needs.

- Safety Protection: The transmission part is enclosed below the platform, reducing safety hazards. The filling and sealing part is installed within a semi-enclosed, anti-static outer frame cover, which facilitates observation and operation while effectively preventing contamination.

- Flexible Configuration: Options for inclined and vertical tube magazines are available to meet the needs of different production environments. The shaping manipulator can shear the tube tail into a right angle or rounded corner, satisfying customers’ diverse packaging requirements.

- Intelligent Alarm and Protection: The equipment is equipped with fault alarm and overload shutdown functions. It immediately stops upon detecting abnormalities, effectively preventing equipment damage and production accidents.

- Energy-saving and Environmental Protection: With low air consumption, optimized hot sealing power, and chiller power, it meets the requirements of energy conservation and environmental protection.

III. Working Principle

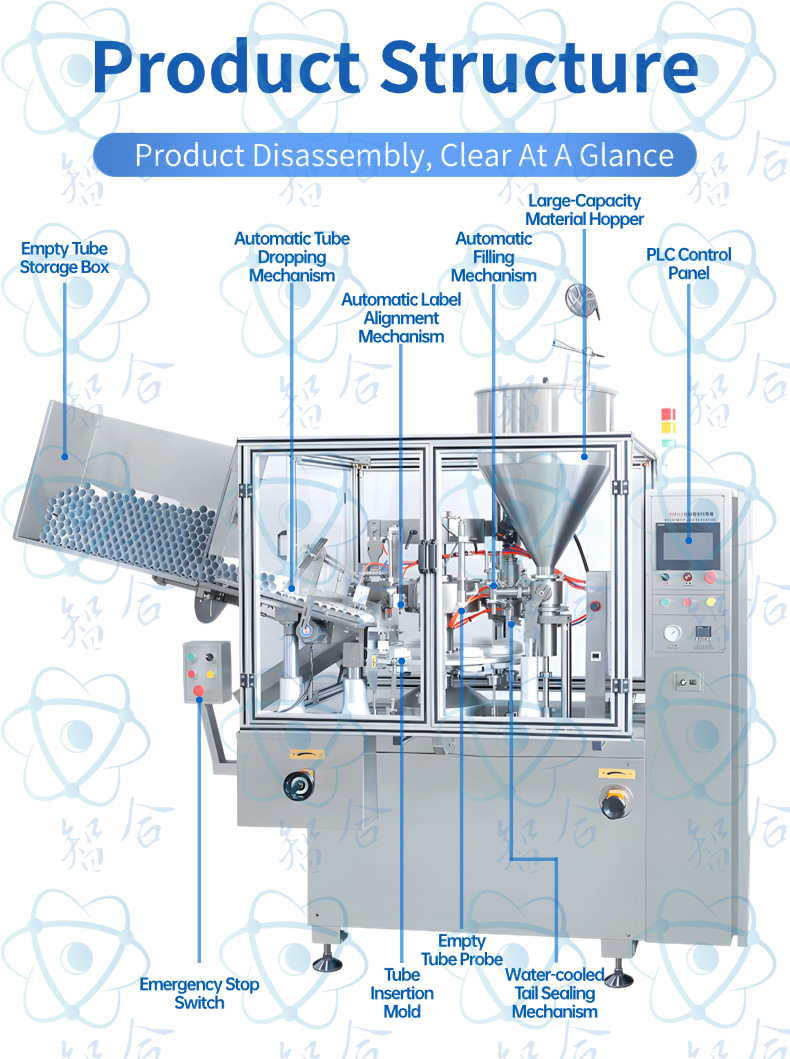

- Automatic Tube Supply: Tubes are automatically conveyed to the working area through the tube magazine. The vacuum adsorption device and tube pressing device on the arcuate arm interact to accurately feed the tube into the tube loading station.

- Color Mark Alignment: The photoelectric color mark alignment station controls high-precision probes and stepper motors to ensure accurate alignment of tube patterns.

- Filling: Once the tube is in position, the filling system starts to work, precisely filling the material into the tube.

- Internal Heating and Sealing: The LEISTER hot air gun blows hot air from the inside of the tube to melt the plastic, followed by embossing and sealing (with optional coding), completing the sealing operation.

- Tail Cutting and Ejection: The shaping manipulator cuts the tube tail according to settings, and the finished product is automatically ejected to the collection area.

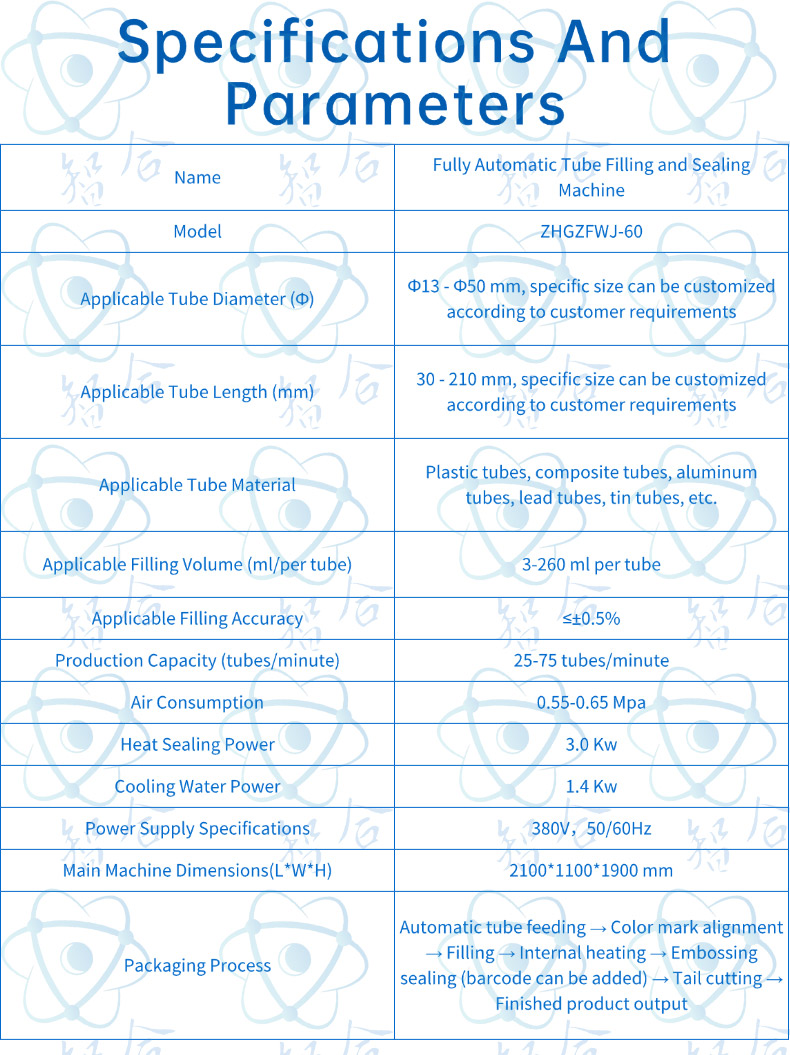

- Technical Specifications

- Model: ZHGZFWJ-60

• Applicable Tube Diameter: Φ 13- Φ 50 mm (specific sizes can be customized)

• Applicable Tube Length: 30 – 210 mm (specific sizes can be customized)

• Applicable Tube Types: Plastic tubes, laminated tubes, aluminum tubes, lead tubes, tin tubes, etc.

• Applicable Packaging Capacity: 3-260 milliliters per tube

• Packaging Accuracy: ≤±0.5%

• Production Capacity: 25-75 tubes per minute

• Air Consumption: 0.55-0.65 Mpa

• Hot Sealing Power: 3.0 Kw

• Chiller Power: 1.4 Kw

• Power Specification: 380V, 50/60Hz

• Dimensions of the Main Unit: 2100*1100*1900 mm

In summary, the ZHGZFWJ-60 automatic tube filling and sealing machine, with its efficient, precise, and automated features, serves as a valuable assistant on numerous industry production lines.