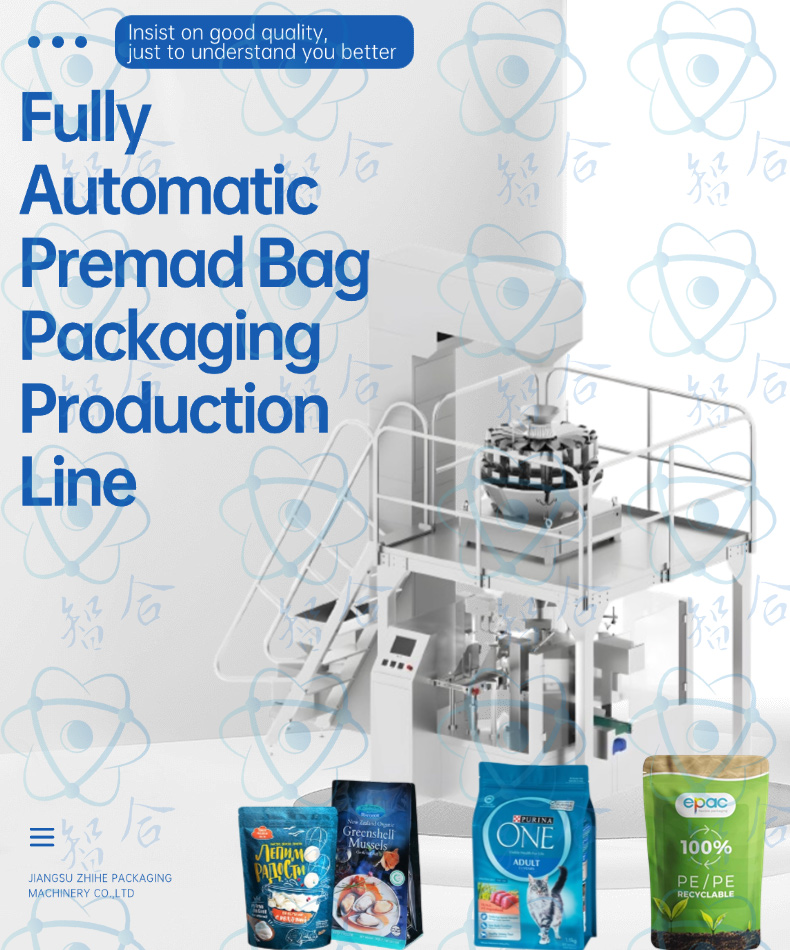

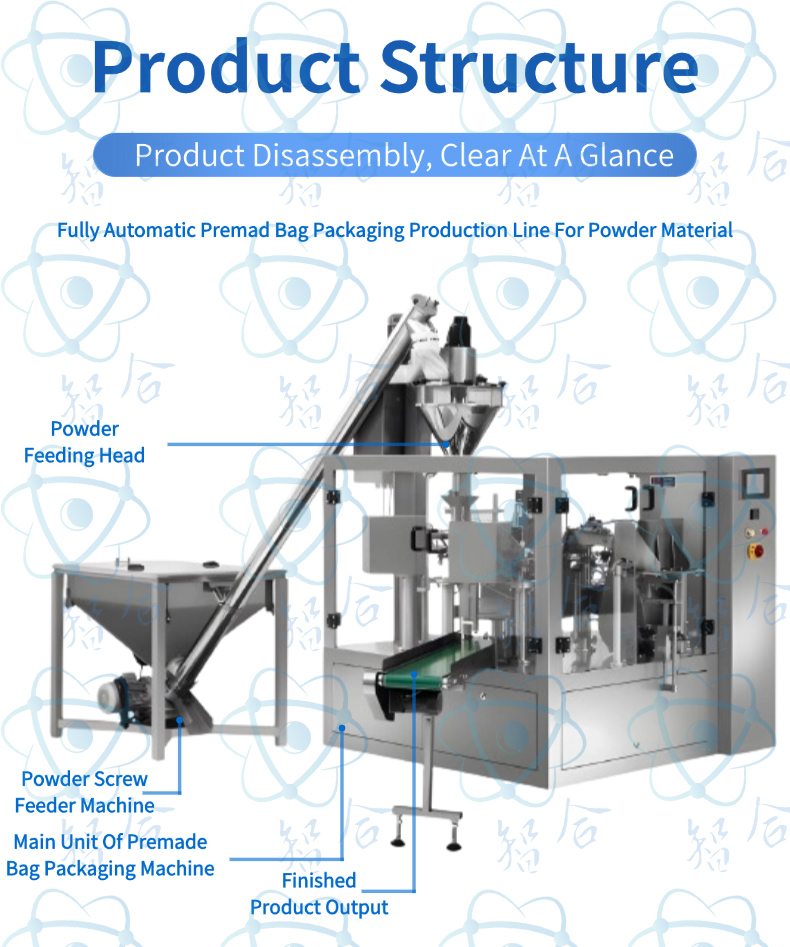

Fully Automatic Premade Bag Packaging Production Line, as a leader in the modern packaging industry, integrates advanced automation technology, precise mechanical design, and intelligent control systems. It provides efficient, precise, and hygienic packaging solutions for various industries such as food, daily chemicals, medical, pharmaceuticals, pesticides, and more. Below is a detailed description of the technical characteristics and working principles of this production line:

Fully Automatic Premade Bag Packaging Production Line, as a leader in the modern packaging industry, integrates advanced automation technology, precise mechanical design, and intelligent control systems. It provides efficient, precise, and hygienic packaging solutions for various industries such as food, daily chemicals, medical, pharmaceuticals, pesticides, and more. Below is a detailed description of the technical characteristics and working principles of this production line:

Technical Characteristics

Safe and Durable Materials: The main body of the entire production line is constructed using 304 stainless steel. For special materials requiring higher corrosion resistance, 316 stainless steel can be selected to ensure that the production environment complies with international standards such as GMP (Good Manufacturing Practices) and FDA (U.S. Food and Drug Administration), safeguarding product safety and preventing contamination.

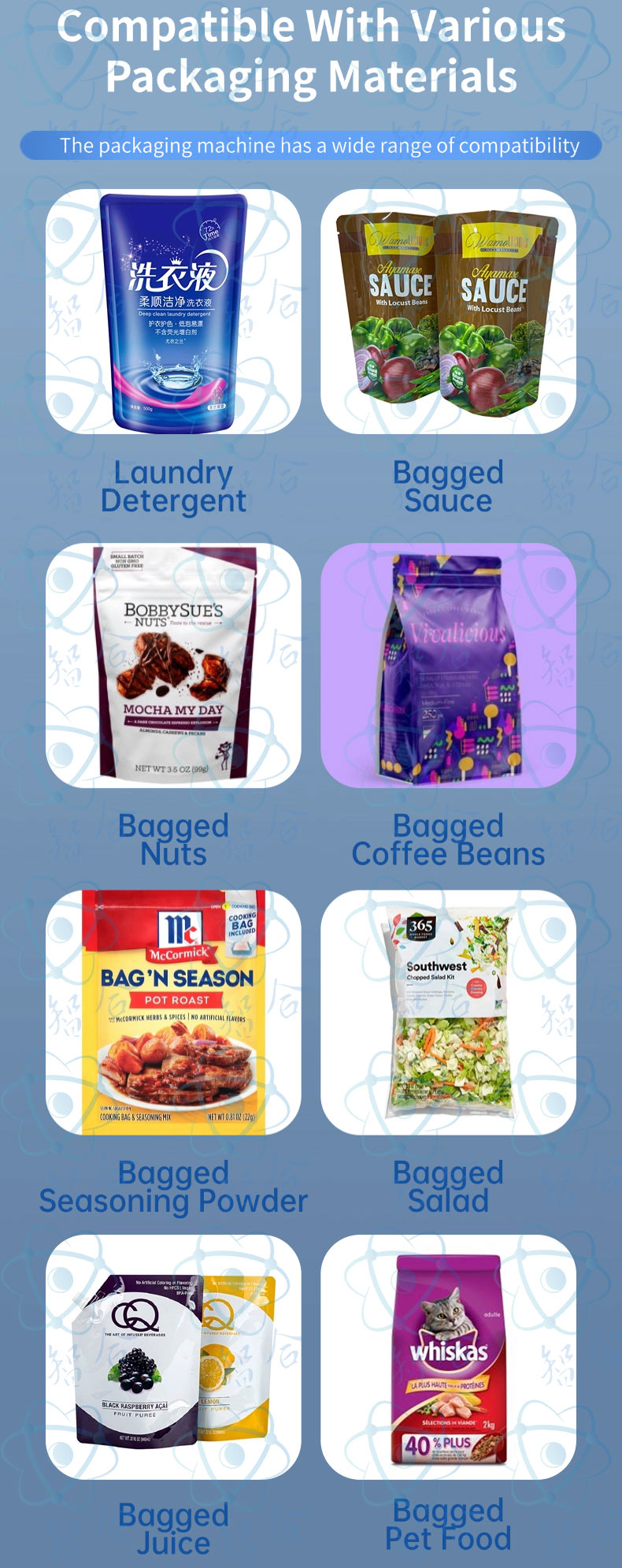

High Flexibility: By replacing different specifications of metering instruments, such as screw meters, liquid pumps, powder filling machines, etc., it can easily adapt to the packaging needs of various materials like granules, liquids, powders, semi-fluids, etc., greatly improving the versatility and flexibility of the production line.

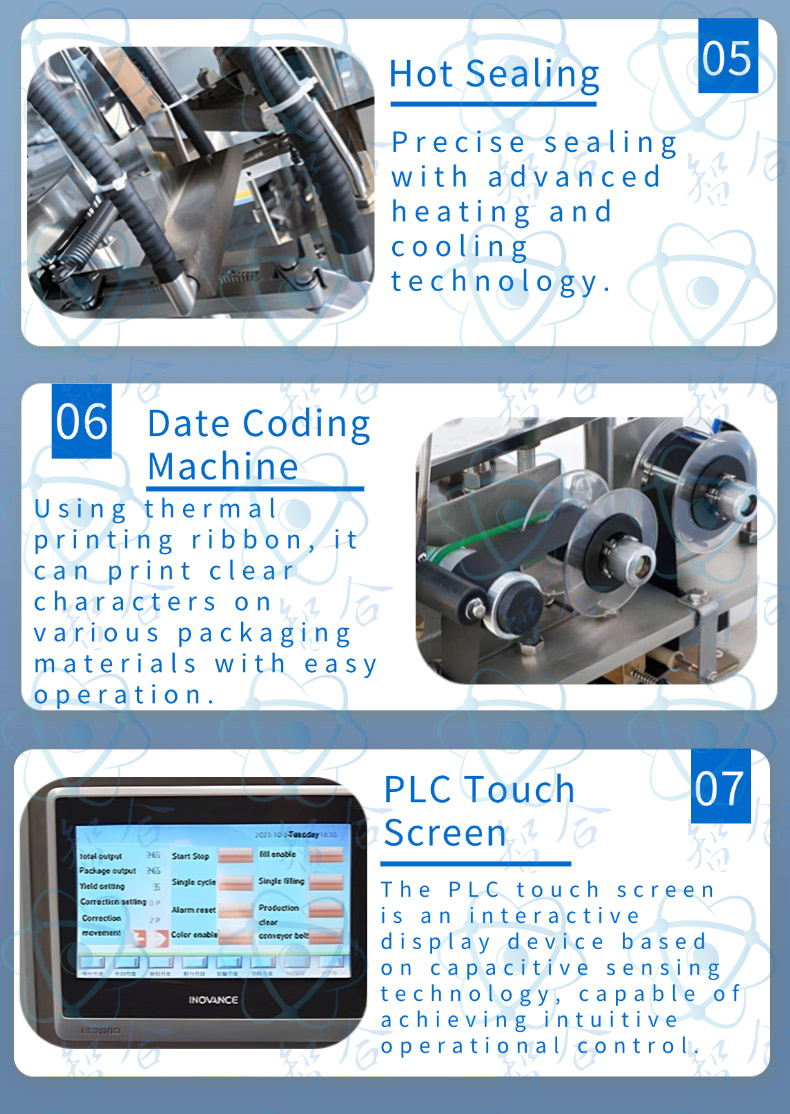

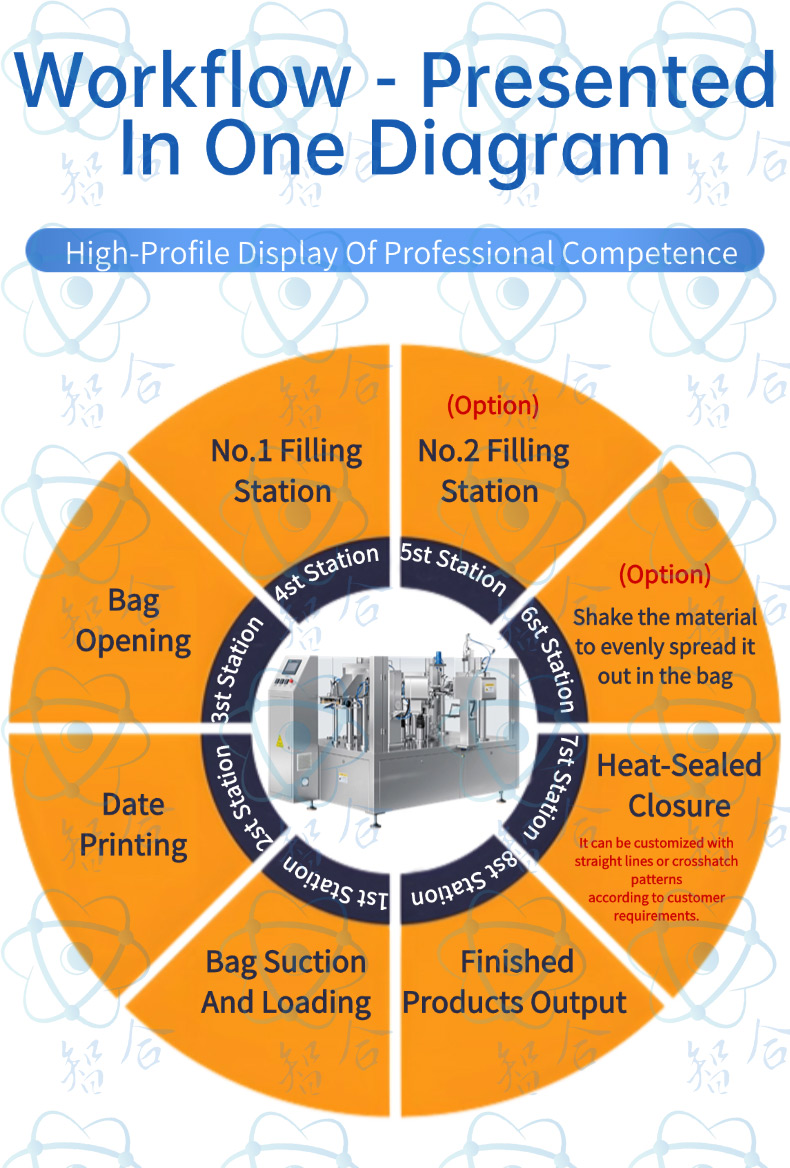

Intelligent Automation: It realizes a fully automated process from bag fetching, coding (printable with production dates, batch numbers, and other information), bag opening, bag opening detection (ensuring the bag is correctly opened without damage), filling, filling detection (ensuring accurate filling volume), heat sealing (using a high-efficiency heating system to ensure a strong and aesthetic seal), to finished product output. Advanced sensors and control systems are equipped to ensure precise and flawless operation at every step.

Efficient Production: Utilizing multi-head electronic scales for rapid and precise metering, combined with a high-speed bag-feeding mechanism, significantly enhances packaging speed, meeting large-scale production demands. Additionally, the entire line design supports 24/7 uninterrupted operation, greatly improving production efficiency.

Quality Assurance: Integrated bag opening and filling detection functions effectively avoid issues such as unopened bags, missing or insufficient filling, ensuring that every product meets quality standards. The heat sealing system adopts advanced temperature control technology to ensure stable and reliable sealing quality.

Modular Design: According to customer needs, auxiliary equipment such as elevators, vacuum pumps, stainless steel worktables, etc., can be flexibly configured to meet the needs of different packaging forms (such as doypack,stand-up bags, flat bags, four-side-sealed bags, etc.) and special processes (such as vacuum packaging, gas-filled packaging).

Working Principles

Bag Fetching and Positioning: Bags are accurately grasped from the bag storage device by a robotic arm or suction cup and positioned at the bag-opening station.

Coding and Bag Opening: After printing necessary information on the bag surface, mechanical or pneumatic devices are used to open the bag mouth, preparing it for filling.

Bag Opening Detection: Using photoelectric sensors or image recognition technology, it detects whether the bag has been successfully opened and is not damaged, ensuring smooth subsequent filling.

Precise Filling: According to preset parameters, multi-head electronic scales or corresponding metering instruments accurately fill the material into the bag.

Filling Detection: Sensors are used again to detect whether the filling volume meets the standard, preventing missing or overfilling.

Heat Sealing: After filling, the bag is conveyed to the heat-sealing station, where heating bars or hot plates are used to heat-seal the bag mouth, ensuring sealing tightness.

Finished Product Output: The sealed packaged products are conveyed to the finished product collection area via a conveyor belt or directly connected to subsequent packaging or logistics systems.

In summary, the Fully Automatic Intelligent High-Speed Bag-Feeding Packaging Production Line, with its efficient, intelligent, and flexible characteristics, provides strong support for modern industrial production and is one of the key equipment driving industrial upgrading and enhancing product competitiveness.