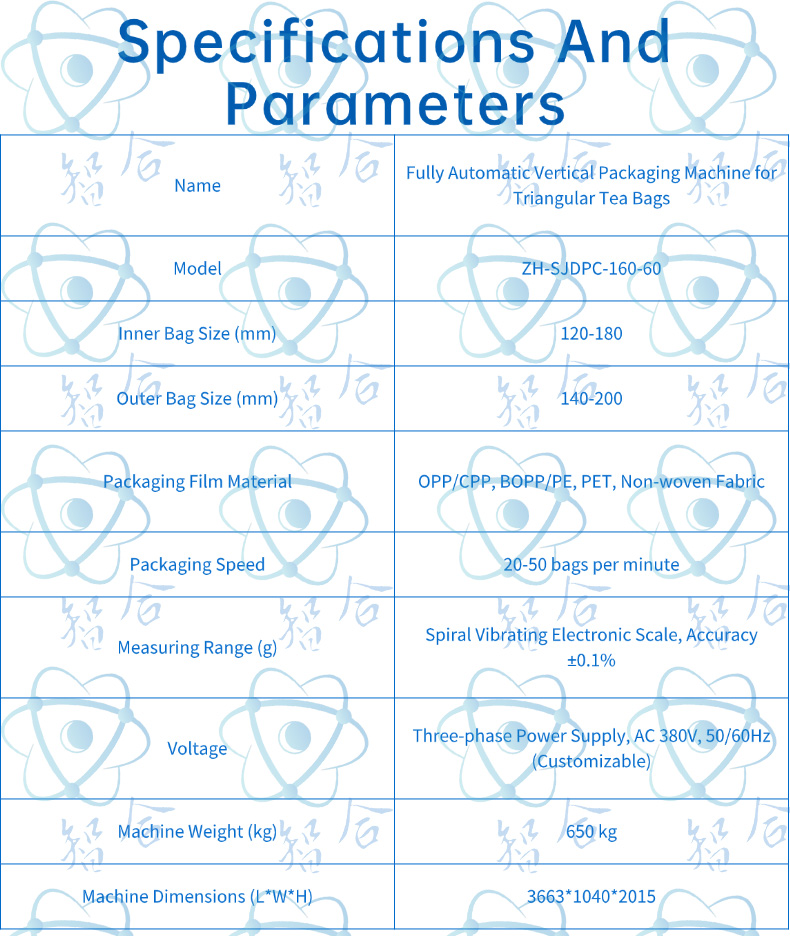

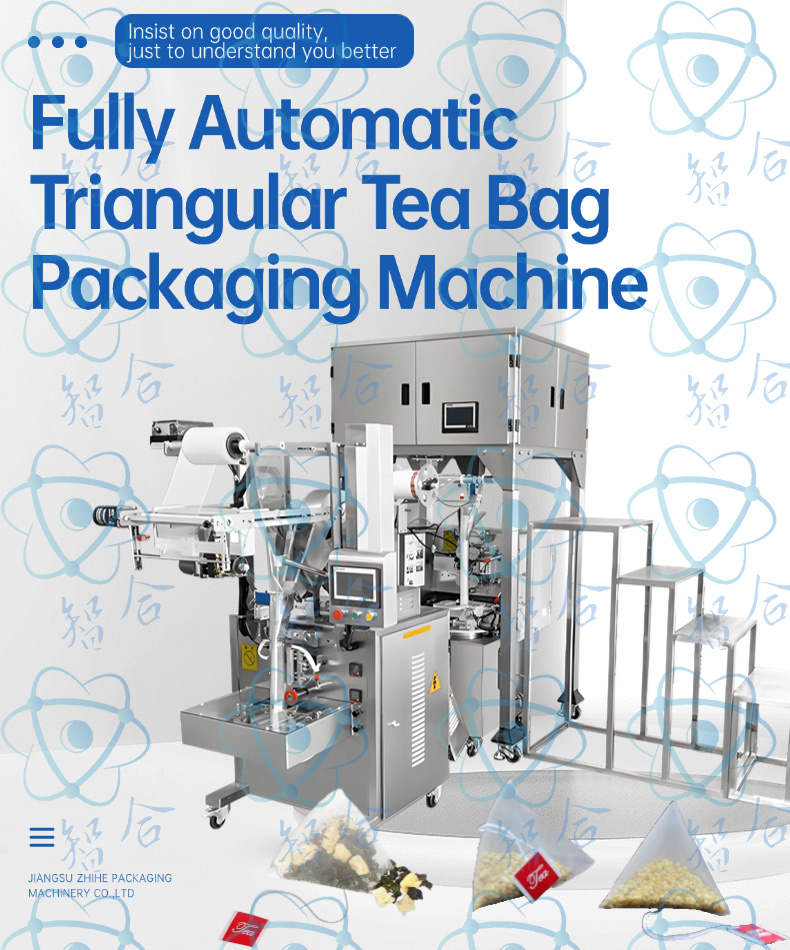

Fully Automatic Vertical Packaging Machine for Triangular Tea Bags: Detailed Description

Fully Automatic Vertical Packaging Machine for Triangular Tea Bags: Detailed Description

This fully automatic vertical packaging machine for triangular tea bags is a highly efficient and automated packaging equipment for tea and similar granular products, integrating the essence of modern mechanical engineering and electronic technology. Below is a detailed description of the product, including its technical features, working principles, and in-depth analysis of its components.

Technical Features

- High-Efficiency Production Capacity: Designed with a high-speed operating system, the packaging machine boasts a packaging capacity of thousands of bags per hour, with specific figures varying based on models and configurations. For instance, some models can reach 3,000 bags per hour, ensuring efficiency in large-scale production.

- Precise Measurement: Equipped with a spiral electronic scale metering device, it can accurately control the weight of each tea bag, guaranteeing the stability and consistency of product quality. Additionally, optional electronic scale metering methods are available for different shapes and densities of tea.

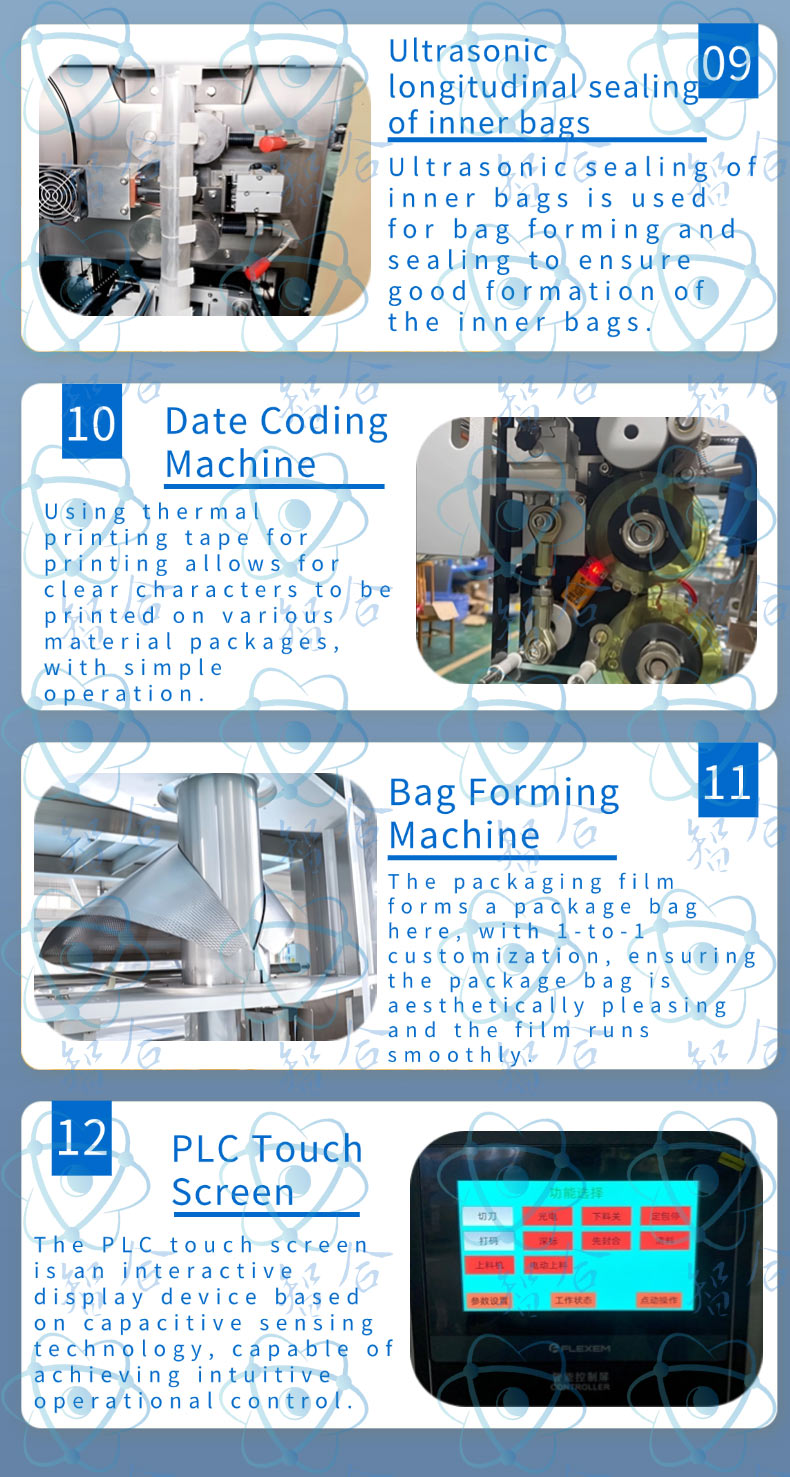

- Advanced Sealing Technology: Utilizing ultrasonic sealing technology, it achieves a firm seal on the packaging bags through ultrasonic longitudinal sealing of the inner bag and thermal sealing and cutting knives of the outer bag. This technology not only enhances sealing speed but also extends the shelf life of the product.

- Intelligent Operation: Equipped with a PLC touchscreen, the operation interface is intuitive and easy to understand. Various parameters, such as packaging quantity, weight, and sealing temperature, can be set through the touchscreen for intelligent control.

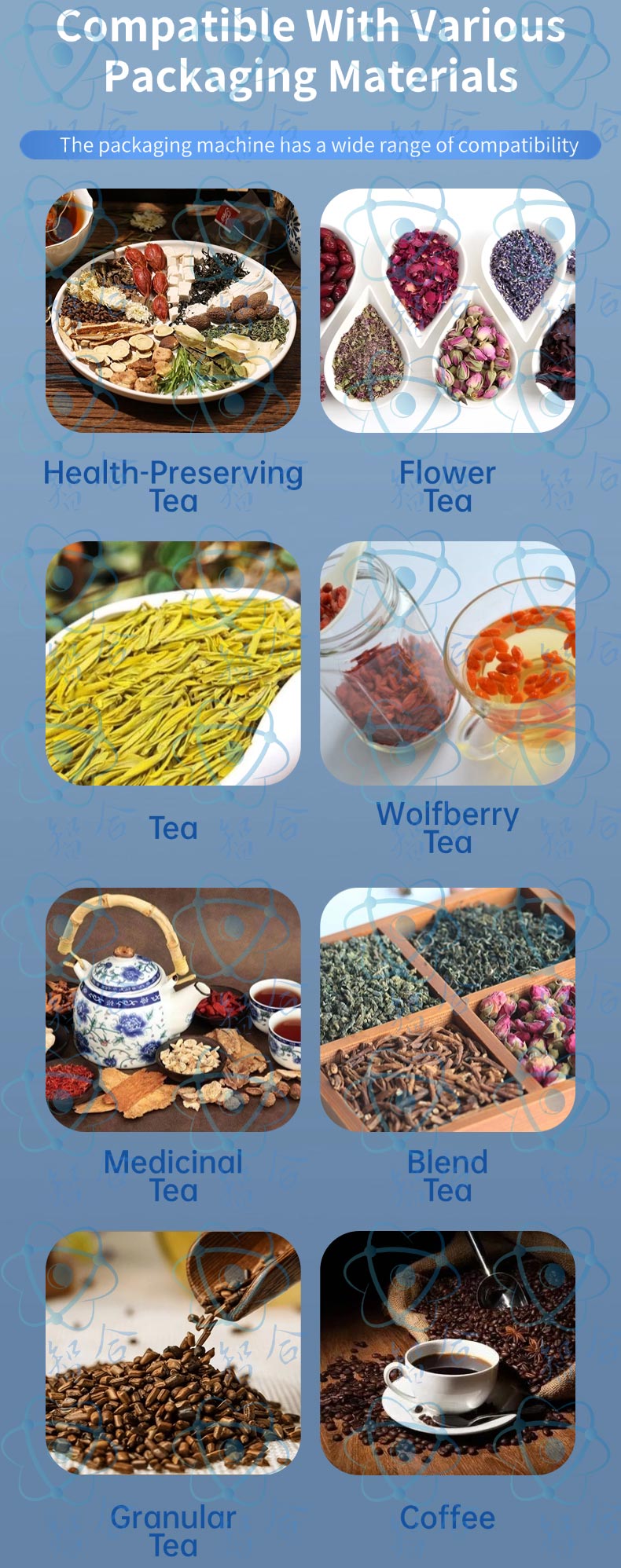

- Versatility: Supports multiple packaging materials and sizes, such as nylon, PET, non-woven fabric, etc., and can customize different specifications of tea bags based on customer demands. Meanwhile, it can be used for various forms such as flat bags and triangular three-dimensional packaging, meeting the diversified needs of the market.

- Safety Protection: The equipment is equipped with protective covers and various safety protection devices, such as door safety limit switches, no packaging material alarms, ultrasonic load alarms, etc., ensuring the safety of operators and the stability of the production process.

Working Principle

The working process of the fully automatic vertical packaging machine for triangular tea bags is roughly as follows:

- Loading: Tea is automatically fed into the feed inlet of the packaging machine through a 50-liter large-capacity hopper.

- Measurement: The spiral electronic scale metering device accurately weighs a certain amount of tea based on preset parameters.

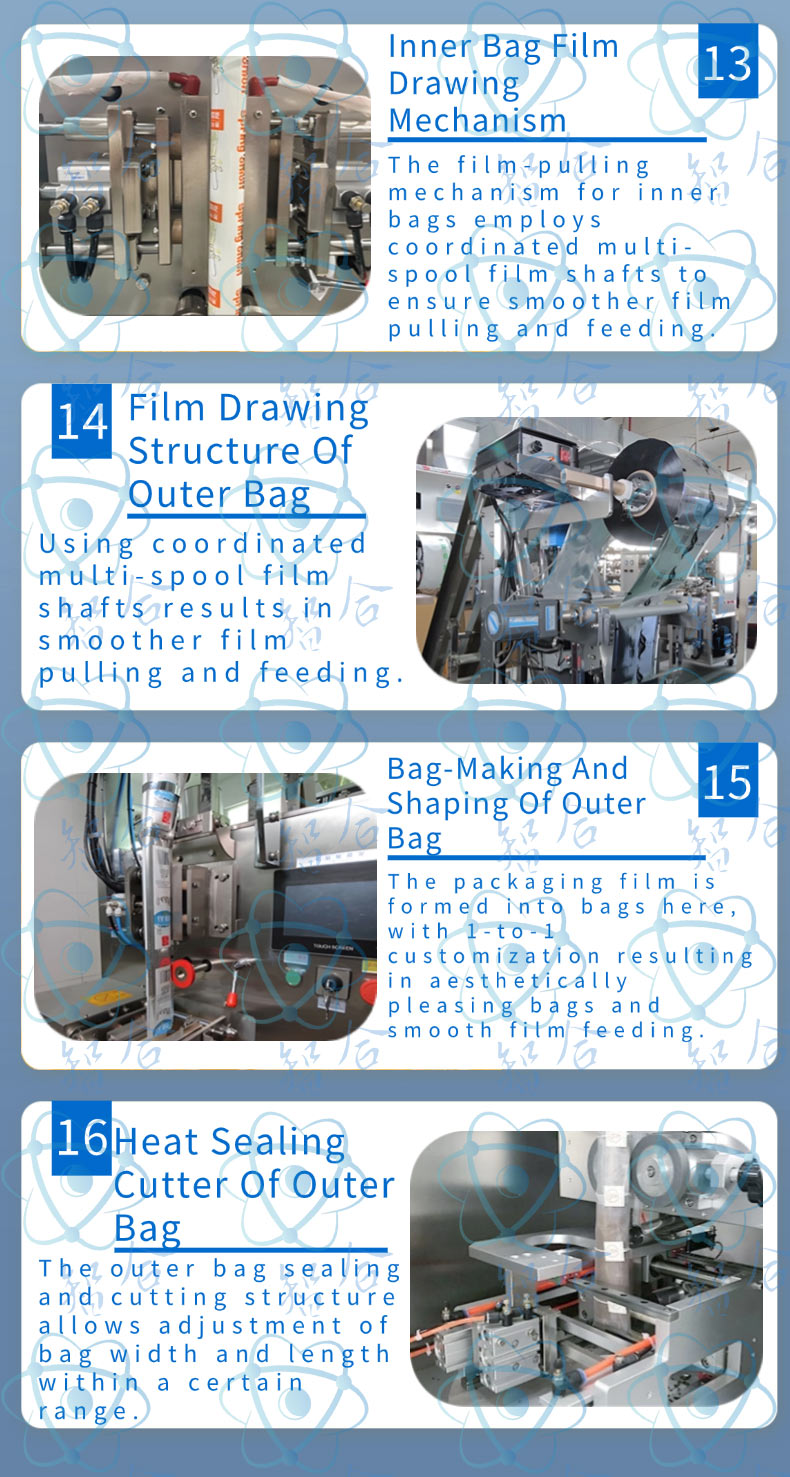

- Bag Forming: The bag-forming device, according to the selected packaging material, stretches the material and forms a predetermined shape of packaging bag through the inner bag film-pulling mechanism and outer bag film-pulling structure.

- Filling and Sealing: The measured tea is fed into the packaging bag, and then the inner bag is initially sealed by ultrasonic longitudinal sealing to prevent tea leakage.

- Outer Bag Sealing and Cutting: After the outer bag is formed, it is finally sealed and cut by the outer bag thermal sealing and cutting knives, forming an independent tea bag.

- Coding and Conveying: A date coder prints information such as the production date and shelf life on the packaging bag, and then the finished product is automatically conveyed out by the conveyor belt for easy collection and packaging.

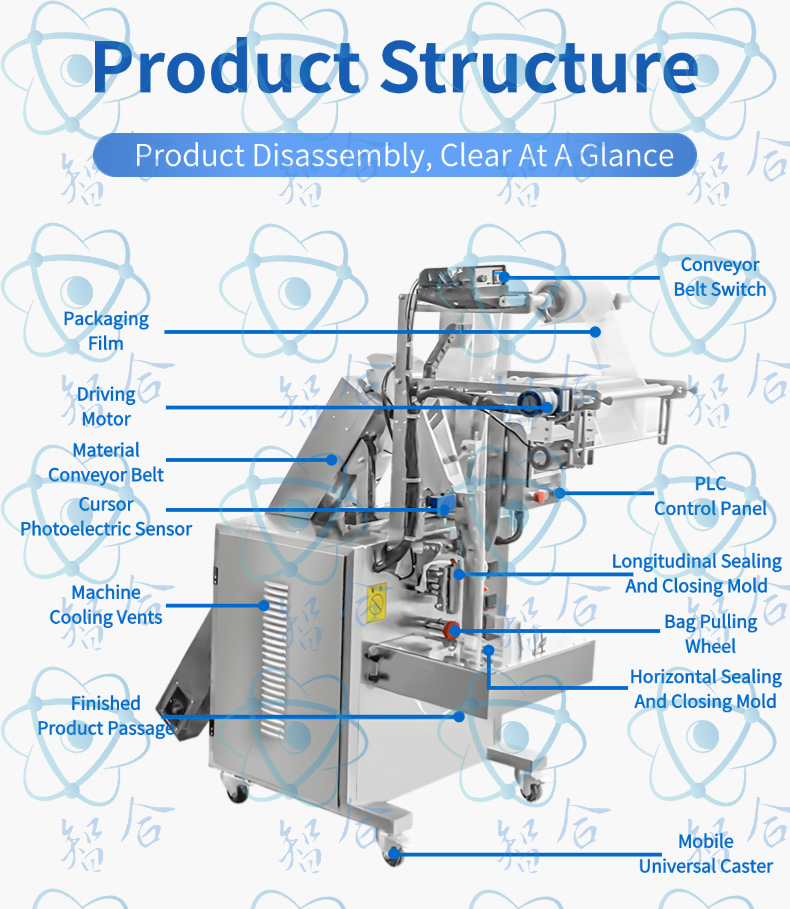

Detailed Explanation of Components

- 50-liter Large-Capacity Hopper: Ensures continuous and stable supply of tea, reducing the frequency of refilling.

- Film Supply Motor: Drives the supply of packaging material to ensure smooth progress of the bag-forming process.

- Finished Product Conveyor Belt: Automatically conveys the packaged tea bags to the collection area.

- Protective Cover: Protects operators from harm by mechanical parts while reducing noise and dust dispersion.

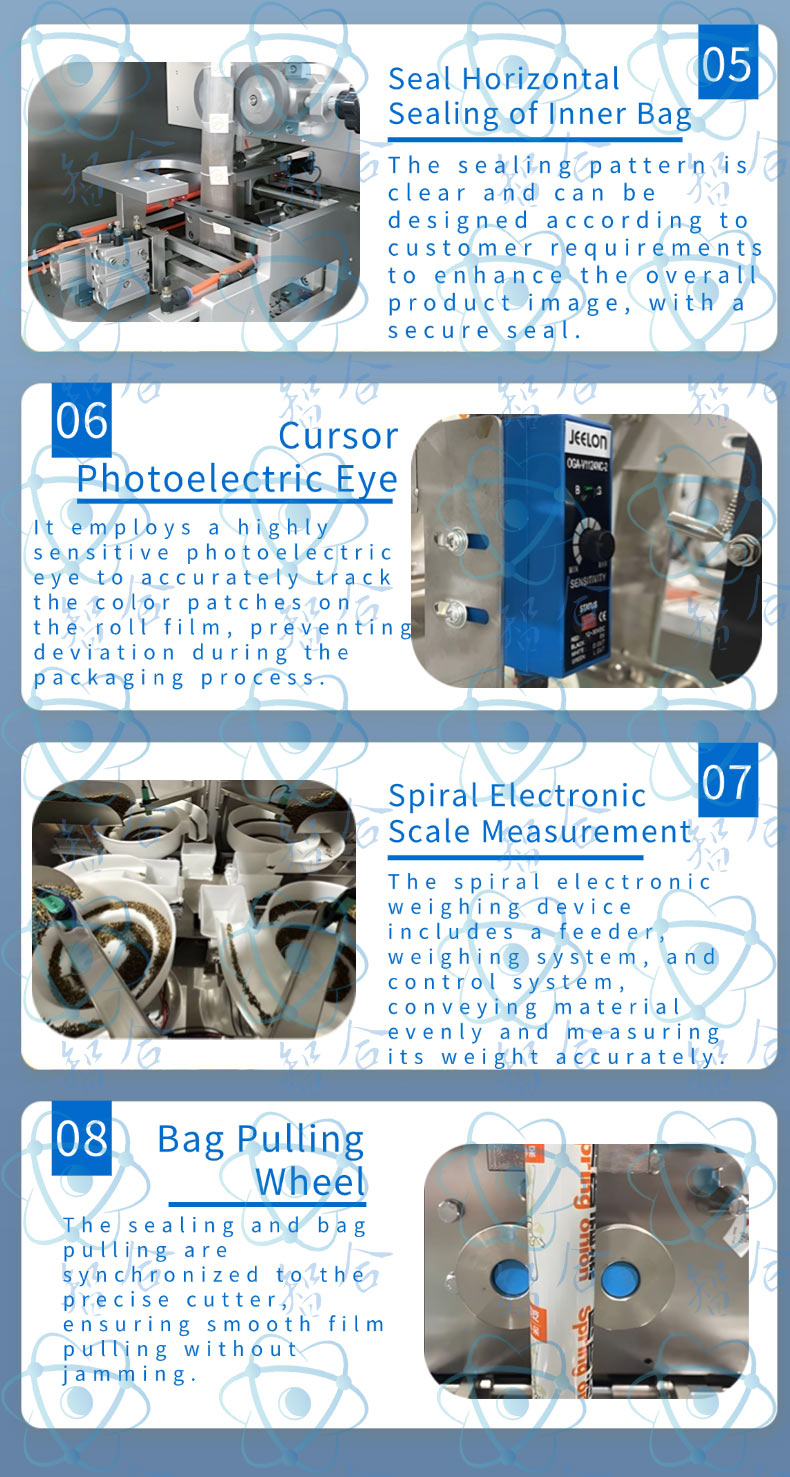

- Inner Bag Horizontal Sealing, Inner Bag Ultrasonic Longitudinal Sealing, Outer Bag Thermal Sealing and Cutting Knives: Collectively constitute the sealing system of the packaging machine, ensuring the seal tightness of tea bags.

- Optical Sensor: Detects the position and status of the packaging material to ensure the accuracy of bag-forming.

- Spiral Electronic Scale Metering Device: Precisely controls the filling amount of tea.

- Bag-Pulling Wheel, Inner Bag Film-Pulling Mechanism, Outer Bag Film-Pulling Structure: Work together to achieve stretching and forming of packaging bags.

- PLC Touchscreen: Acts as the control center of the equipment, enabling parameter setting, status monitoring, fault diagnosis, and other functions.

In summary, the fully automatic vertical packaging machine for triangular tea bags, with its high efficiency, precision, intelligent technical features, and comprehensive working principles and components, provides a superior solution for the packaging of tea and other granular products.