The fully automatic powder vertical packaging machine is a highly efficient and precise packaging equipment widely used in various industries such as pharmaceuticals, food, and chemicals. Below is a detailed description of its technical characteristics, working principle, and components.

The fully automatic powder vertical packaging machine is a highly efficient and precise packaging equipment widely used in various industries such as pharmaceuticals, food, and chemicals. Below is a detailed description of its technical characteristics, working principle, and components.

Technical Characteristics:

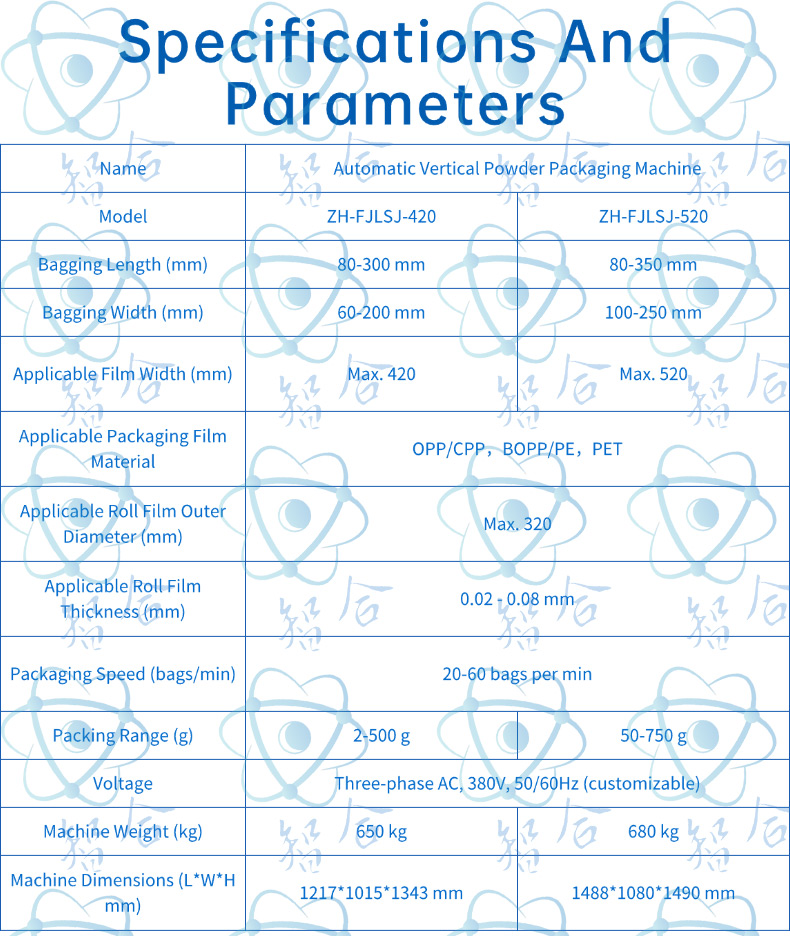

- High Precision: Utilizing a high-precision screw feeder driven by a servo motor, it ensures packaging accuracy of ±0.2 grams or even higher, meeting the stringent requirements of various industries for packaging accuracy.

- High Efficiency: Capable of continuously and stably performing powder metering and packaging operations, enhancing production efficiency. Some advanced models can achieve a packaging speed of 20-60 bags per minute.

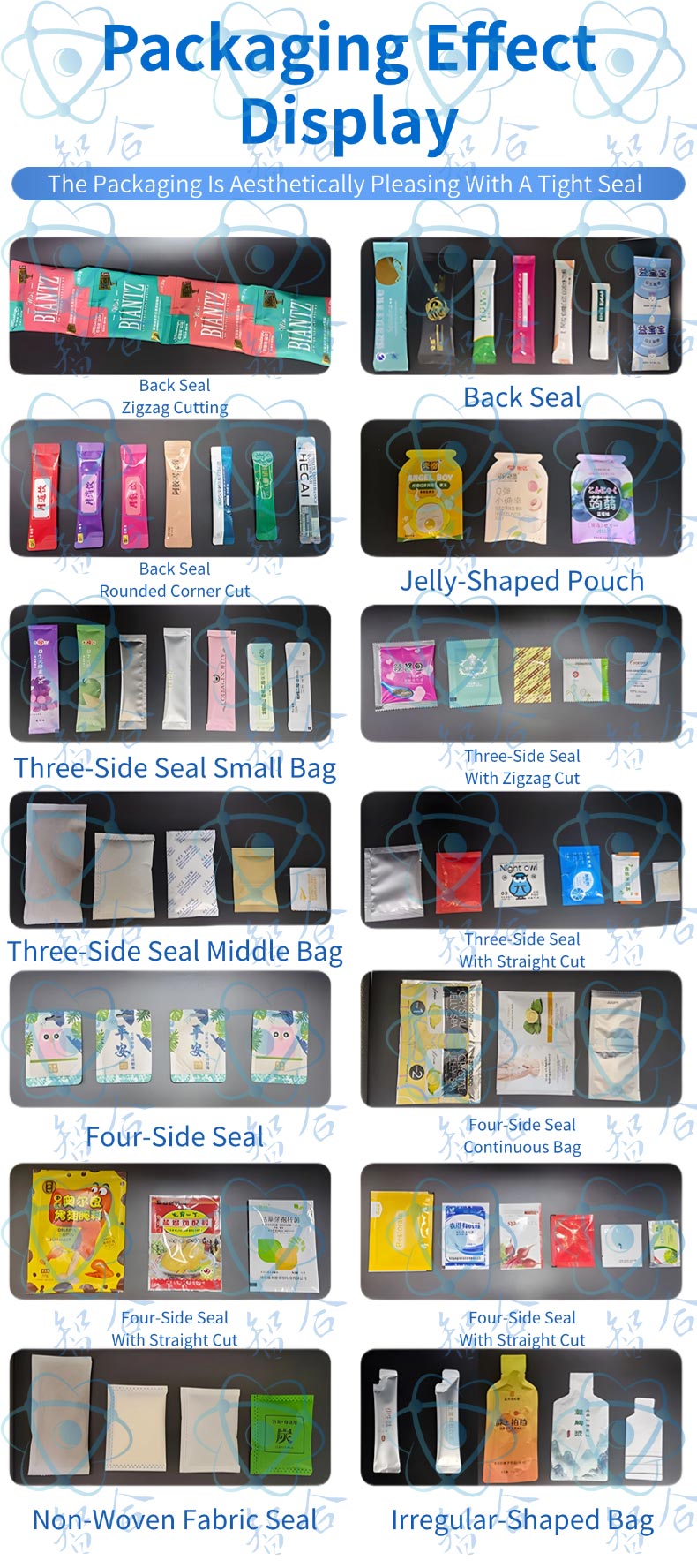

- High Automation: The entire packaging process, from material feeding to sealing, counting, and printing, is automated, significantly reducing manual intervention and improving production efficiency and product consistency.

- Easy Operation and Maintenance: Equipped with a user-friendly human-machine interface for straightforward operation. Additionally, the machine’s design facilitates cleaning and maintenance.

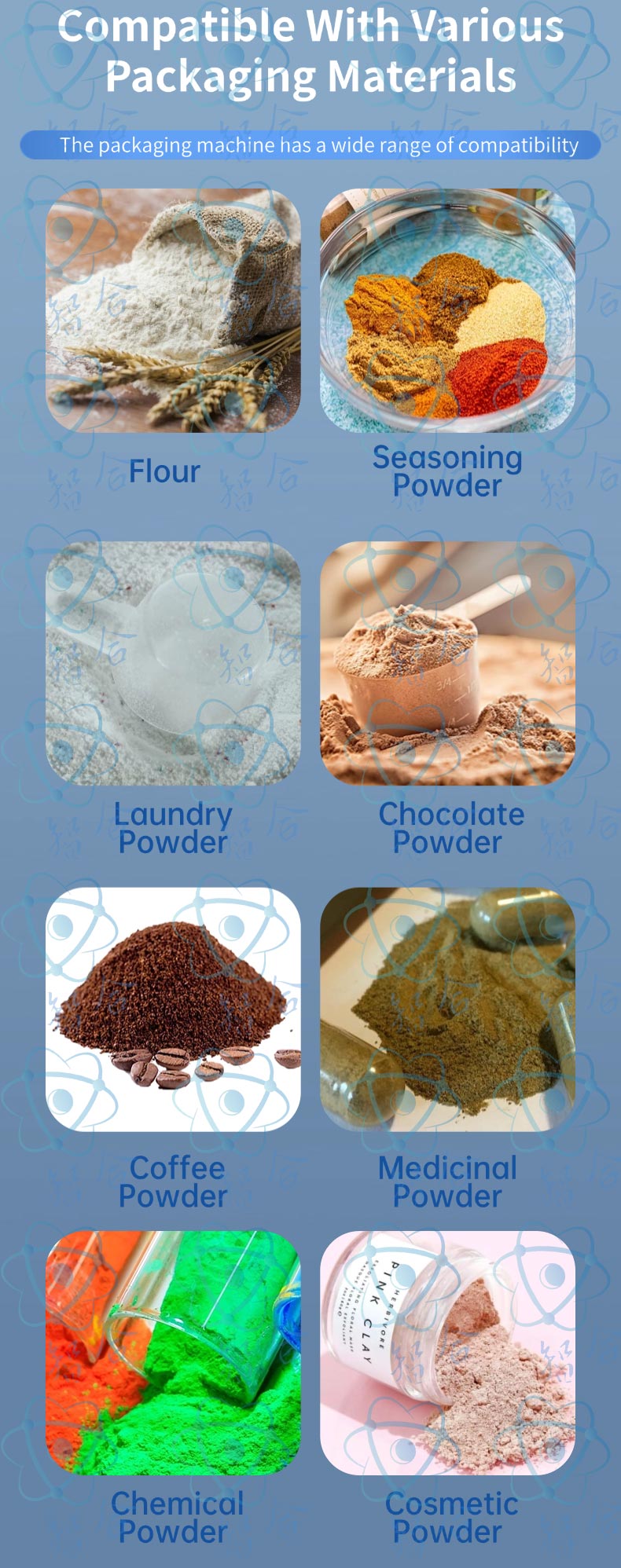

- Strong Adaptability: Suitable for packaging various powder materials and can be customized to meet the packaging needs of different industries and products.

- Environmentally Friendly and Energy-Saving: Featuring a closed structure and advanced exhaust system, it minimizes dust pollution while optimizing energy consumption, reducing production costs.

Working Principle:

The fully automatic powder vertical packaging machine involves the coordinated work of multiple processes, including material feeding, metering and filling, sealing, conveying, and collecting.

- Material Feeding: Powder materials enter the packaging machine through a sealed feeding hopper, ensuring material purity during transportation. The hopper design minimizes dust emission.

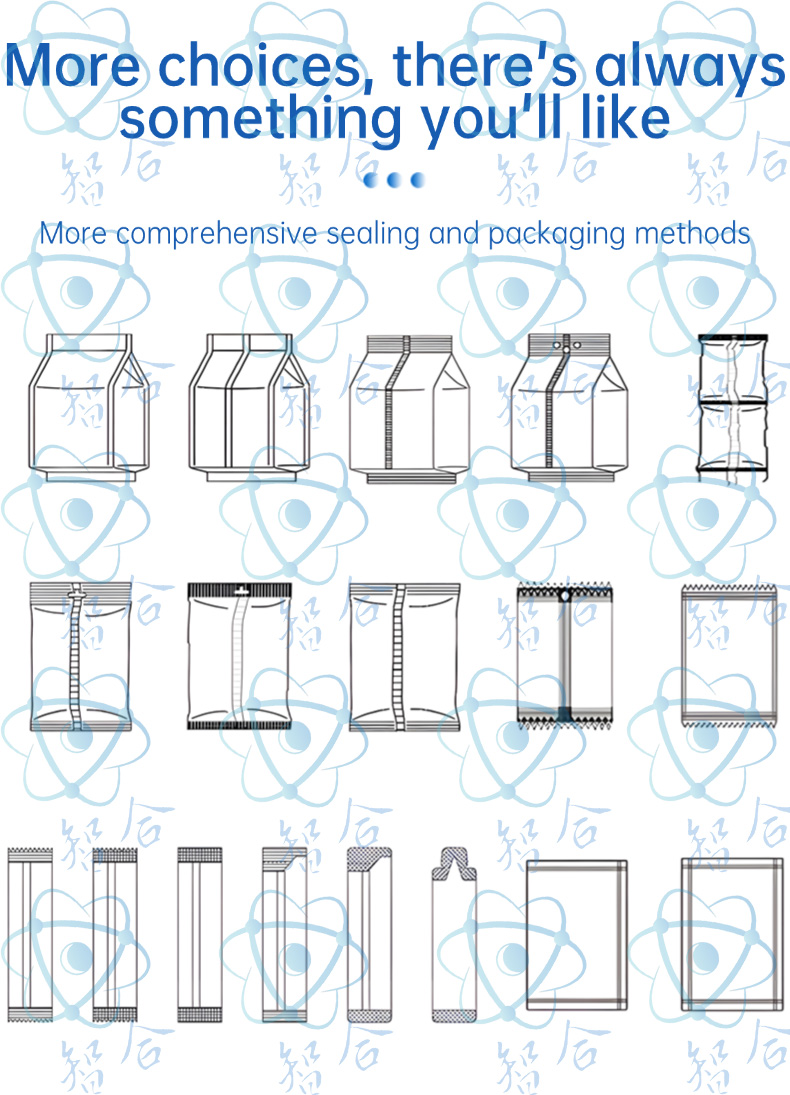

- Metering and Filling: The stirring powder feeder evenly sends materials into the metering system, which precisely calculates and controls the required material quantity for each package based on preset parameters. Upon completion, the material enters the film former’s packaging bag through the screw feeder. The machine also features automatic venting to ensure bag tightness and sealing.

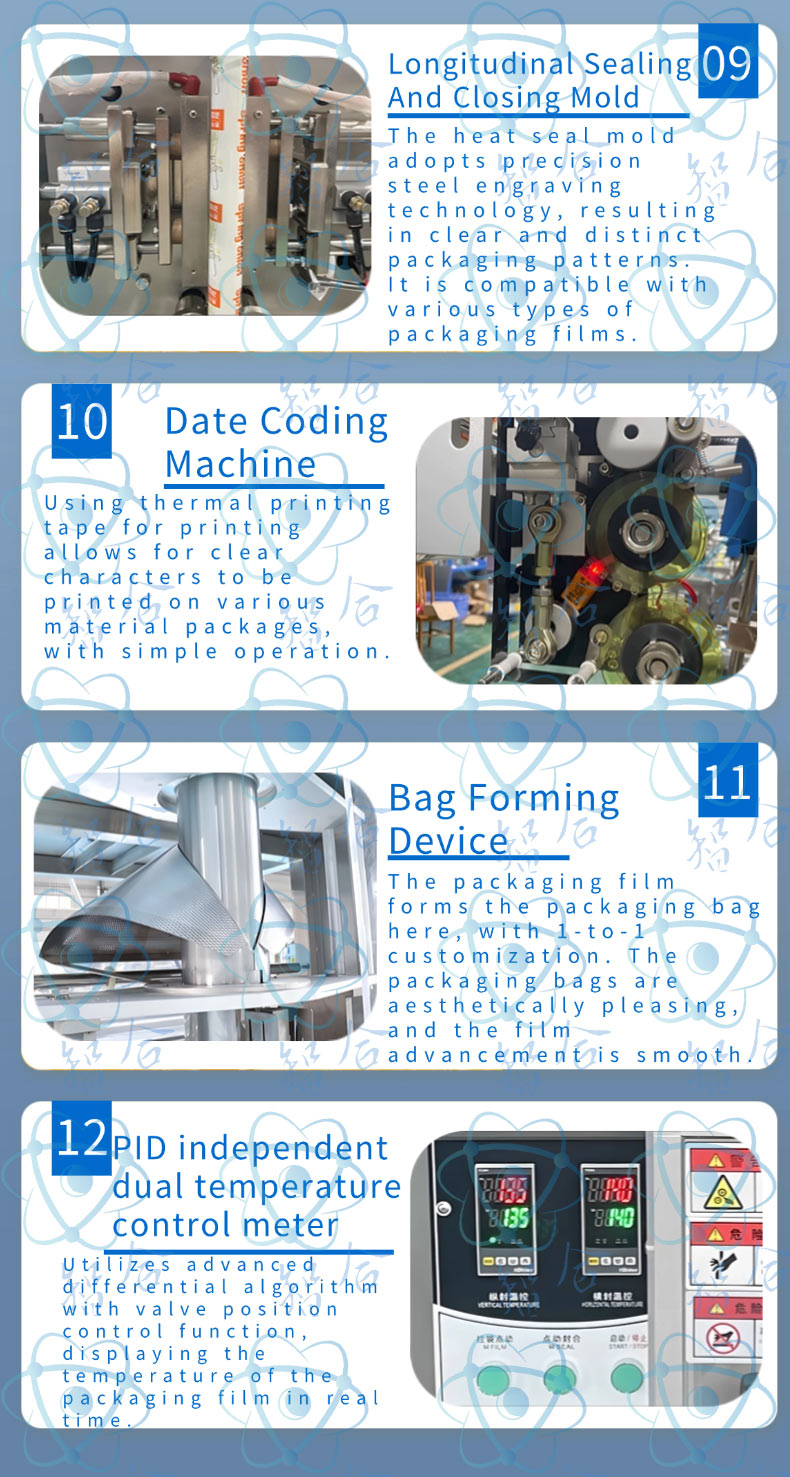

- Sealing: After filling, the bag enters the sealing process. Longitudinal and transverse sealing devices seal the bag, automatically adjusting sealing temperature and pressure based on bag material and thickness to ensure sealing quality. The system also includes automatic detection and correction functions.

- Conveying and Collecting: Sealed bags are smoothly conveyed to a designated collection area via the conveying system, which offers adjustable speed and direction. The collection area is equipped with organized arrangement and collection devices for convenient distribution and use.

Components Explanation:

- Sealed Feeding Hopper: Ensures material purity during transportation and minimizes dust emission.

- Film Support Frame: Holds and supports the film roll, providing a stable film source for packaging.

- Film Control Motor: Drives film feeding and positioning, ensuring precision and stability during packaging.

- Feeding Control Panel: Controls the feeding device’s operation, including speed and material flow adjustments.

- Stirring Powder Feeder: Evenly feeds materials into the metering system, ensuring accurate and stable metering.

- Packaging Control Panel: Acts as the main control center, coordinating the work of various components to achieve automated packaging.

- Emergency Stop Switch: Quickly cuts off power in emergencies, ensuring operational safety.

- Discharge Port: The channel where material enters the packaging bag, designed for even material distribution.

- Mobile Casters: Facilitate equipment movement and installation, enhancing flexibility and adaptability.

- Film Former: Forms the packaging bag’s shape based on preset parameters, preparing it for filling and sealing.

- Longitudinal and Transverse Sealing Devices: Seal the bag, ensuring sealing quality and airtightness.

In conclusion, the fully automatic powder vertical packaging machine plays a vital role in industries like pharmaceuticals, food, and chemicals due to its high precision, efficiency, ease of operation, and adaptability. With continuous technological advancements and market development, this equipment will continue to innovate and improve, providing superior and efficient solutions for various production needs.