The fully automatic vertical granular packaging machine is an integrated packaging equipment featuring automation, high efficiency, and precision, widely applied in various industries such as food, pharmaceuticals, and chemicals, especially catering to the packaging needs of granular materials. Based on the components you provided, the following is a detailed description of its technical characteristics, working principle, and components.

The fully automatic vertical granular packaging machine is an integrated packaging equipment featuring automation, high efficiency, and precision, widely applied in various industries such as food, pharmaceuticals, and chemicals, especially catering to the packaging needs of granular materials. Based on the components you provided, the following is a detailed description of its technical characteristics, working principle, and components.

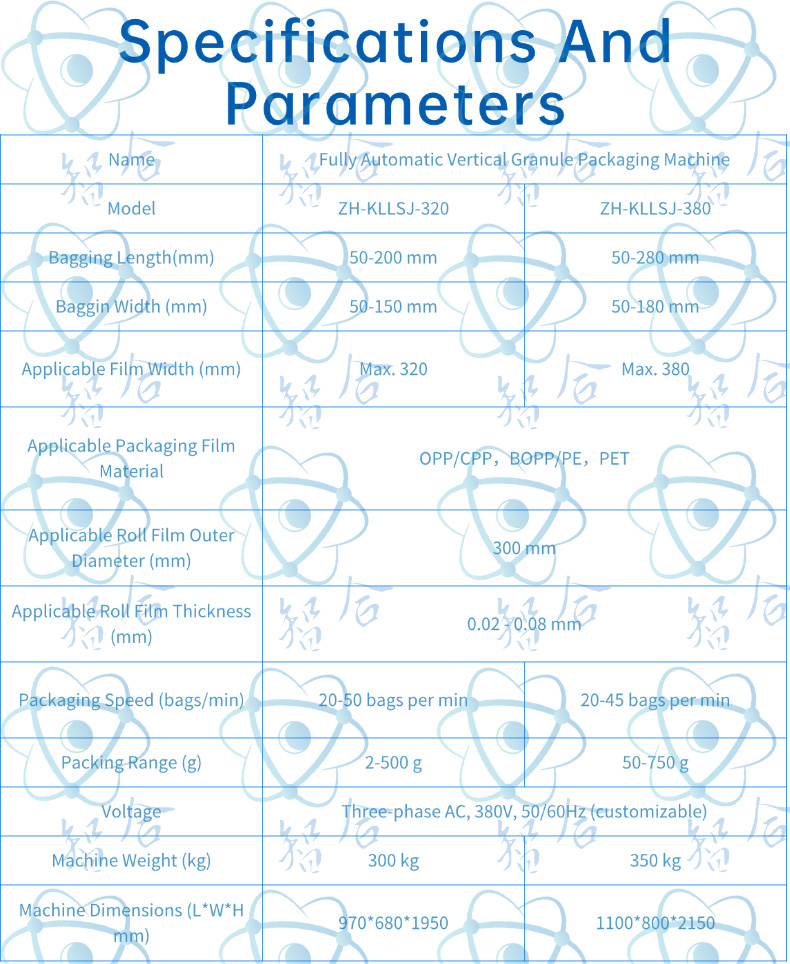

Technical Characteristics

High-precision metering: Equipped with an advanced metering system (cup metering), it ensures precise and error-free weight of materials in each package, enhancing product quality.

High speed and efficiency: The automated control system optimizes the entire packaging process, from feeding to sealing, with tightly connected links, significantly boosting packaging speed and production efficiency.

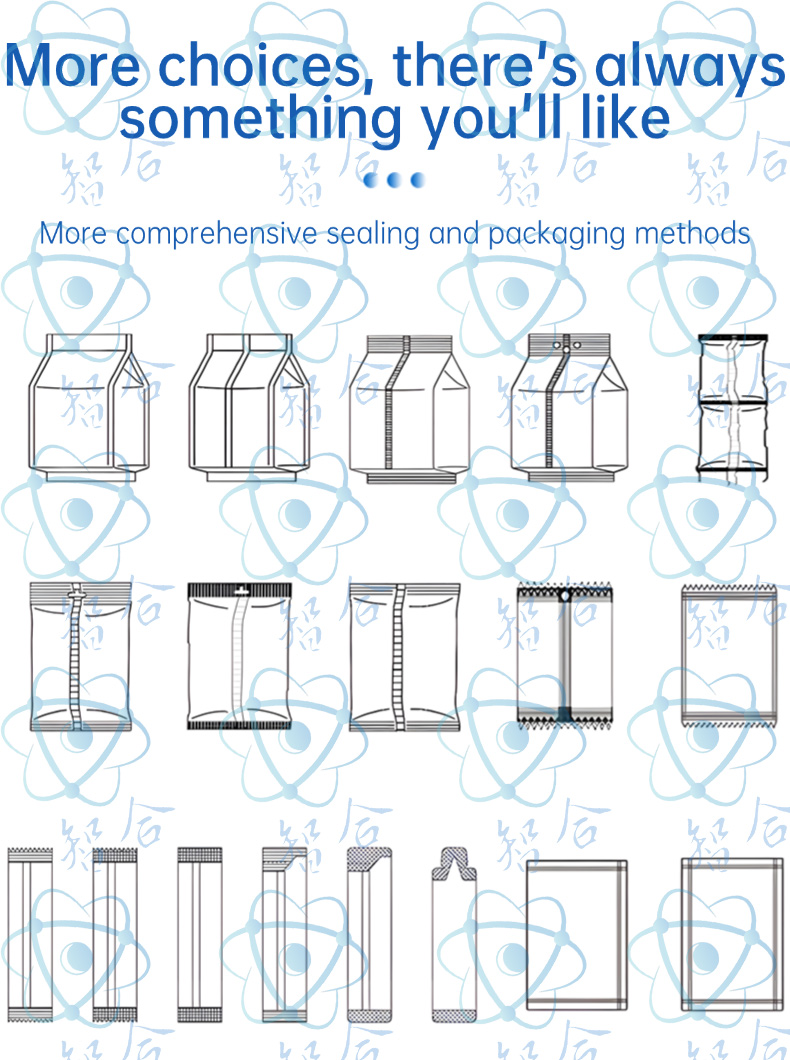

Flexibility: Capable of accommodating different sizes and materials of packaging bags, it is not limited by packaging containers, making it suitable for scenarios where material types and packaging specifications frequently change.

Excellent stability: With a reasonably designed structure, the machine operates stably and reliably, reducing breakdowns and downtime, thereby improving overall equipment utilization.

Easy operation: Featuring digital displays and microcomputer control, the operation interface is intuitive and easy to understand, allowing for seamless switching of working modes and facilitating maintenance.

Working Principle

The working process of the fully automatic vertical granular packaging machine is outlined as follows:

Feeding: The material to be packaged enters the cup feeder through the hopper, flowing evenly and continuously into the bag according to the set weight.

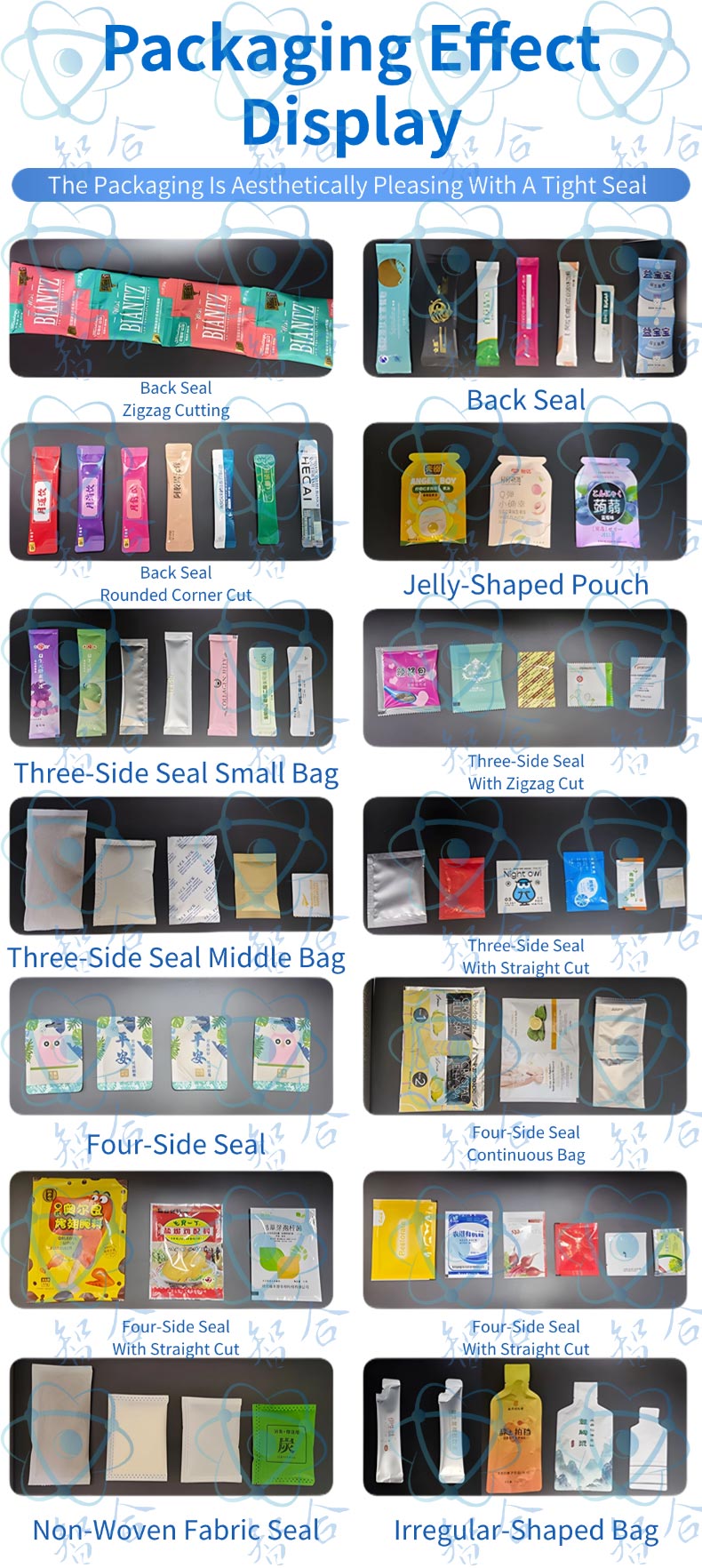

Bag making and filling: The film on the film holder is driven by the film control motor, passing through the film former to shape the packaging bag. The metered material is then fed into the bag through the discharge port, while the bag is initially sealed by the longitudinal sealing device.

Sealing and cutting: Once the bag is filled, the transverse sealing device performs the final sealing, and the cutting device separates the bag from the machine.

Printing (optional): The sealed bag can be printed with information such as production date, specifications, and batch number through the printing device.

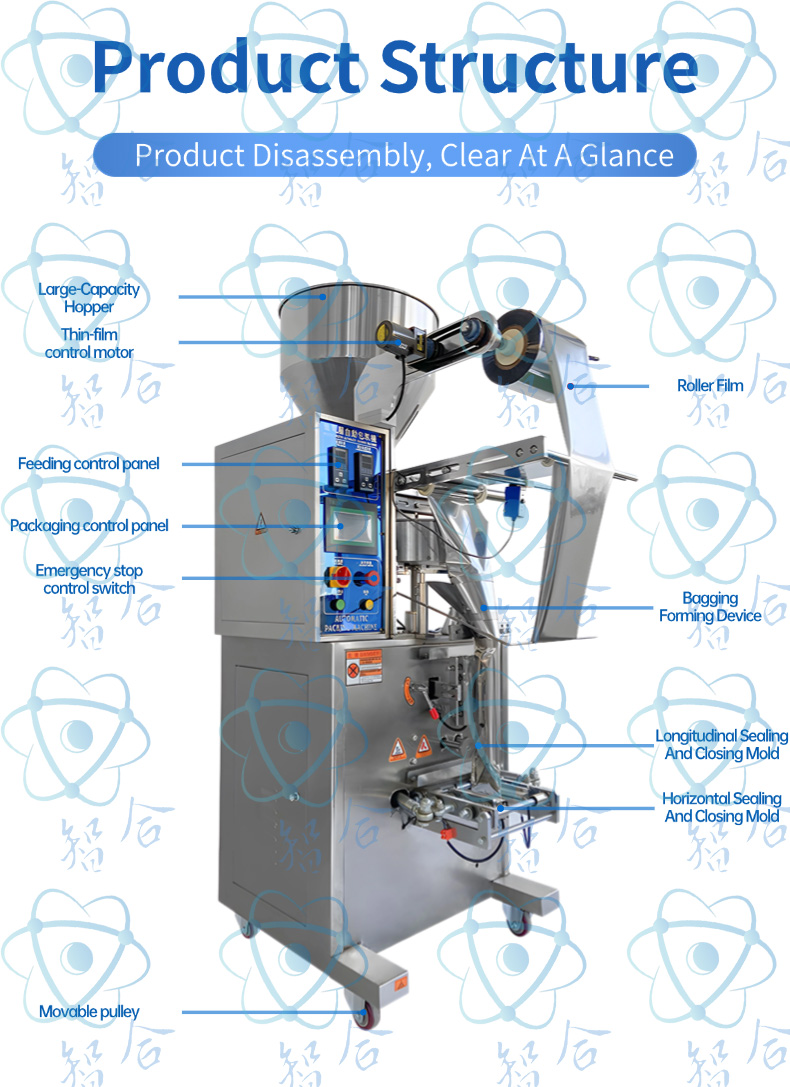

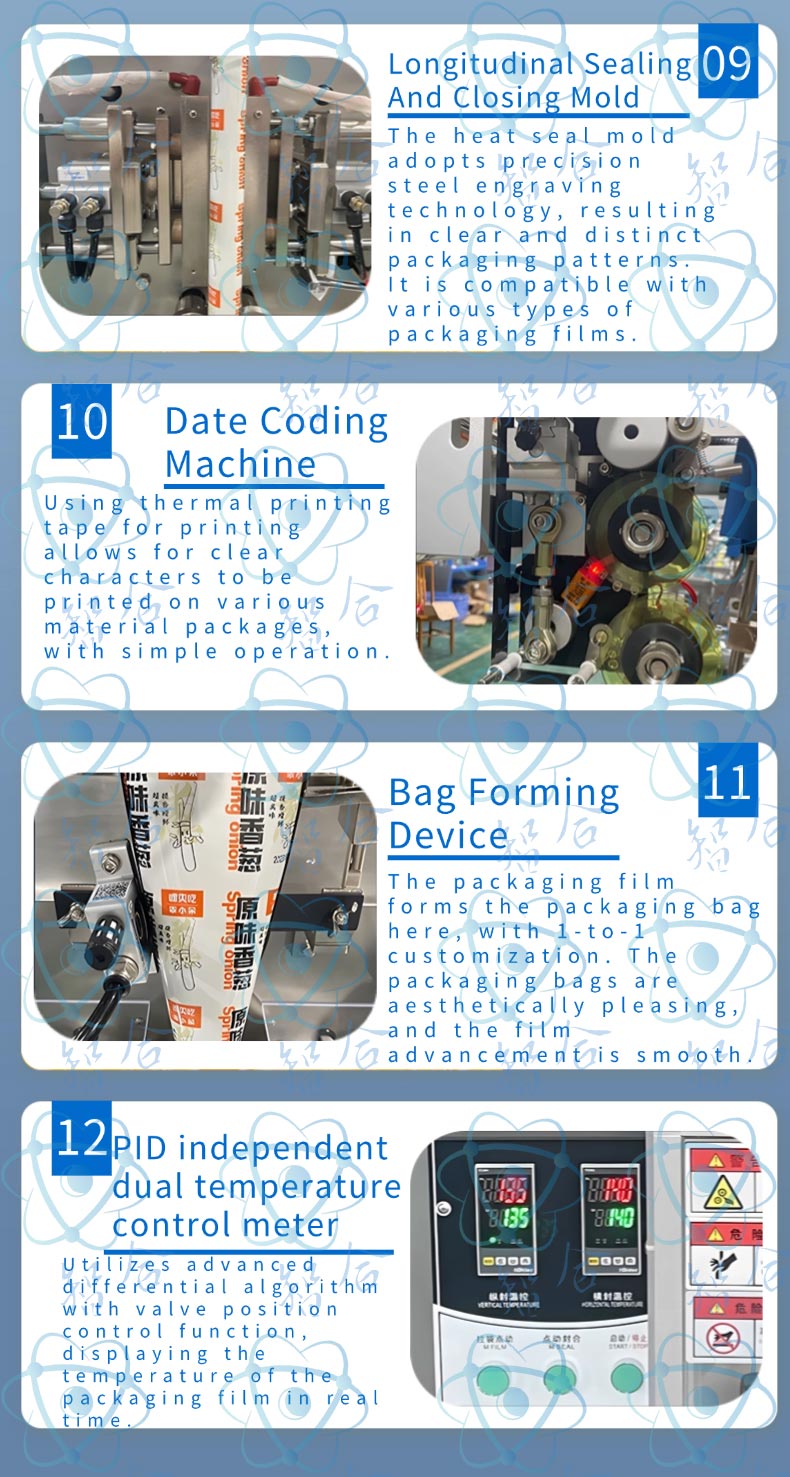

Detailed Description of Components

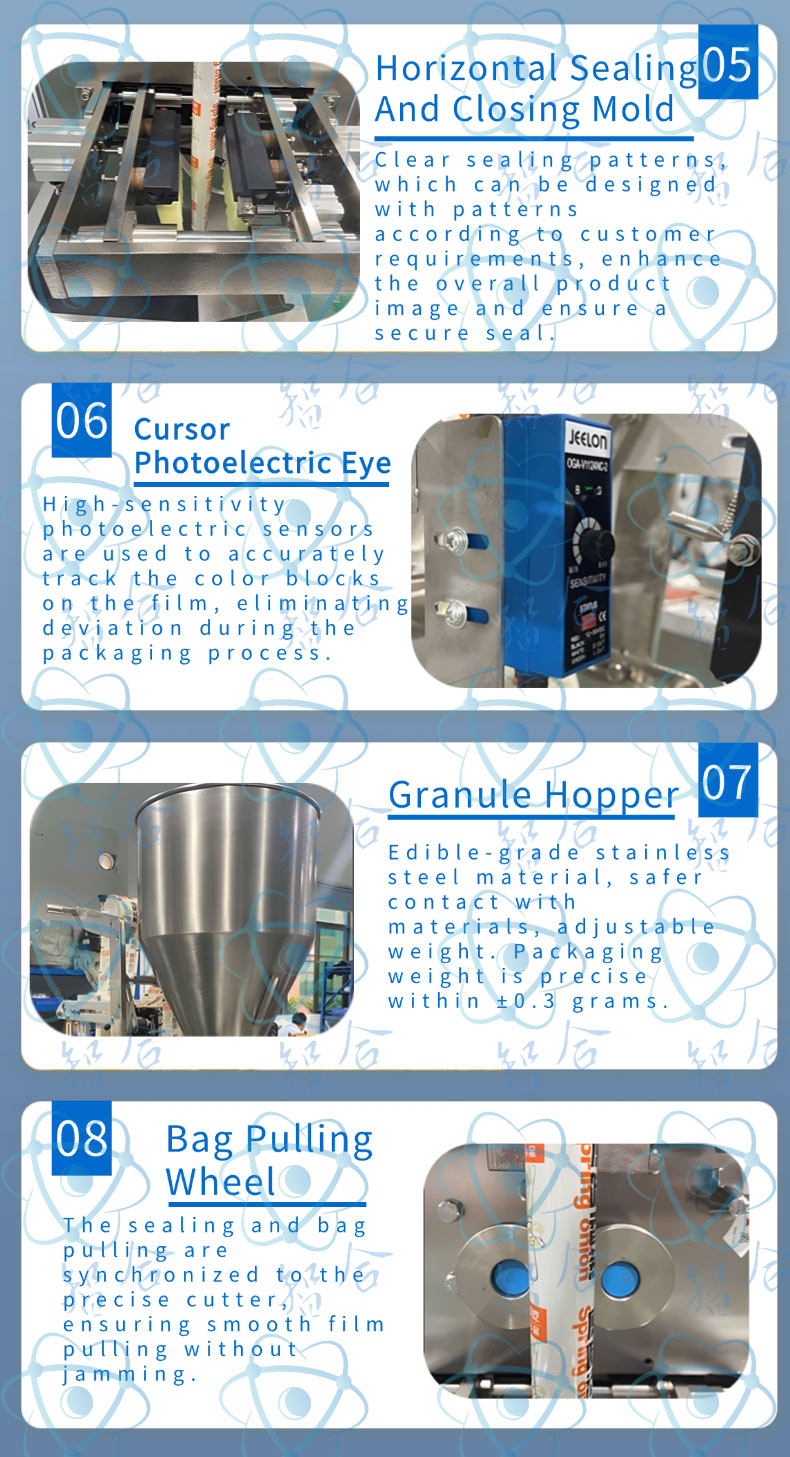

Hopper: Used to store granular materials to be packaged, typically designed as straight or inclined to facilitate smooth material flow to the next stage.

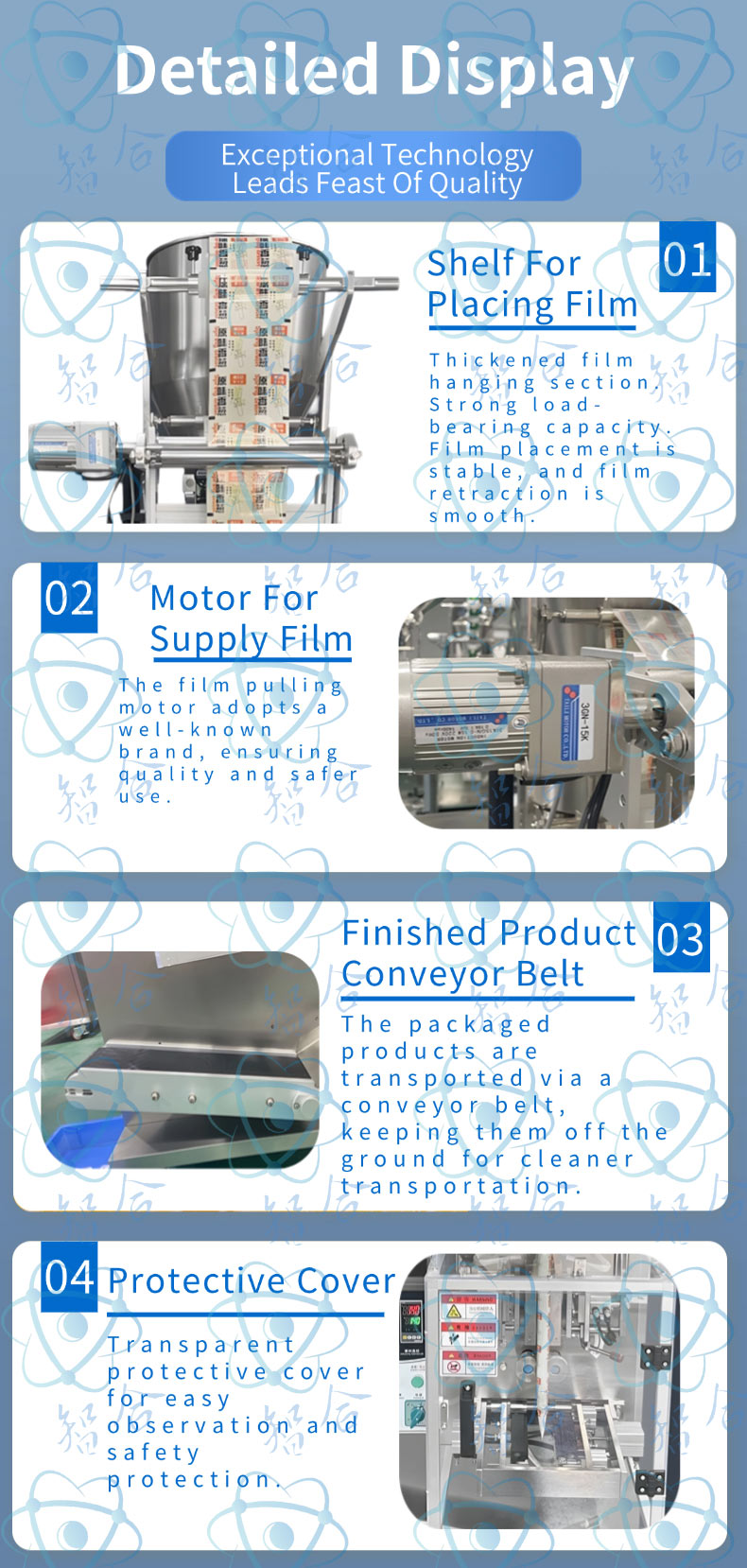

Film holder: Supports and fixes the packaging film, ensuring it remains flat and does not deviate during the packaging process.

Film control motor: Drives the film forward, automatically adjusting the film feed speed according to the packaging speed.

Discharge control panel: Controls the speed and amount of material discharge, typically including adjustment knobs, displays, and other components.

Packaging control panel: The central control hub of the entire packaging machine, integrating various control buttons, indicators, and displays for monitoring and adjusting the machine’s operating status.

Emergency stop switch: A safety device that quickly cuts off the equipment’s power in emergencies to prevent accidents.

Discharge port: The channel where material flows from the metering device into the packaging bag, ensuring smooth flow and minimal clogging.

Mobile casters: Facilitate moving or repositioning the equipment as needed.

Film former: Shapes the film into the packaging bag, fixing it to the former through heat sealing or cold sealing.

Longitudinal and transverse sealing devices: Respectively seal the longitudinal and transverse sides of the packaging bag, ensuring its airtightness.

In summary, the fully automatic vertical granular packaging machine plays a vital role in the packaging of granular materials, leveraging its technical characteristics of high precision, efficiency, and flexibility.