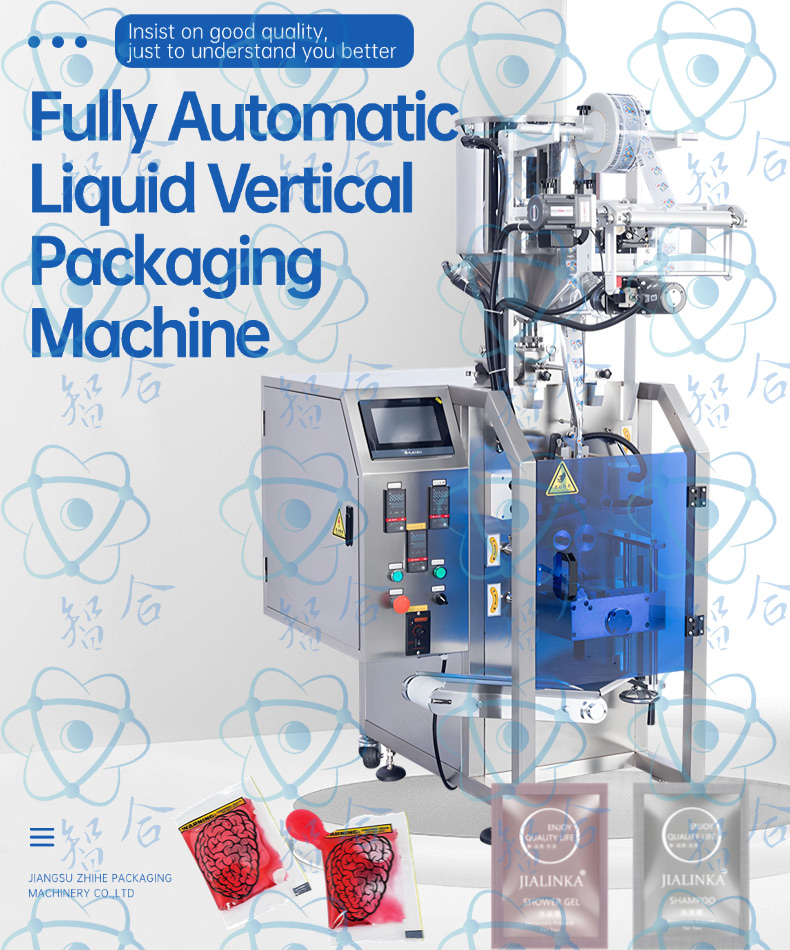

The fully automatic liquid vertical packaging machine is a highly automated and multifunctional equipment specifically designed for packaging various liquid products. Below is a detailed description of this equipment, including its technical features, working principles, and a comprehensive explanation of its various components as mentioned.

The fully automatic liquid vertical packaging machine is a highly automated and multifunctional equipment specifically designed for packaging various liquid products. Below is a detailed description of this equipment, including its technical features, working principles, and a comprehensive explanation of its various components as mentioned.

Technical Features

Efficiency: The fully automatic liquid vertical packaging machine achieves full automation from raw materials to finished products, encompassing functions such as bag making, metering, filling, sealing, cutting, counting, and more, significantly enhancing production efficiency.

Accuracy: Equipped with advanced sensors and control systems, it precisely controls filling volumes and sealing times, ensuring packaging accuracy and precision. The filling capacity is flexibly adjustable to accommodate different product specifications.

Stability: Constructed with high-quality materials and components, the machine undergoes rigorous testing and inspection, ensuring stable and reliable performance for long-term operation.

Safety: Featuring an intelligent control system, it monitors the equipment’s operational status in real-time, promptly alerts and addresses abnormalities, safeguarding operator safety.

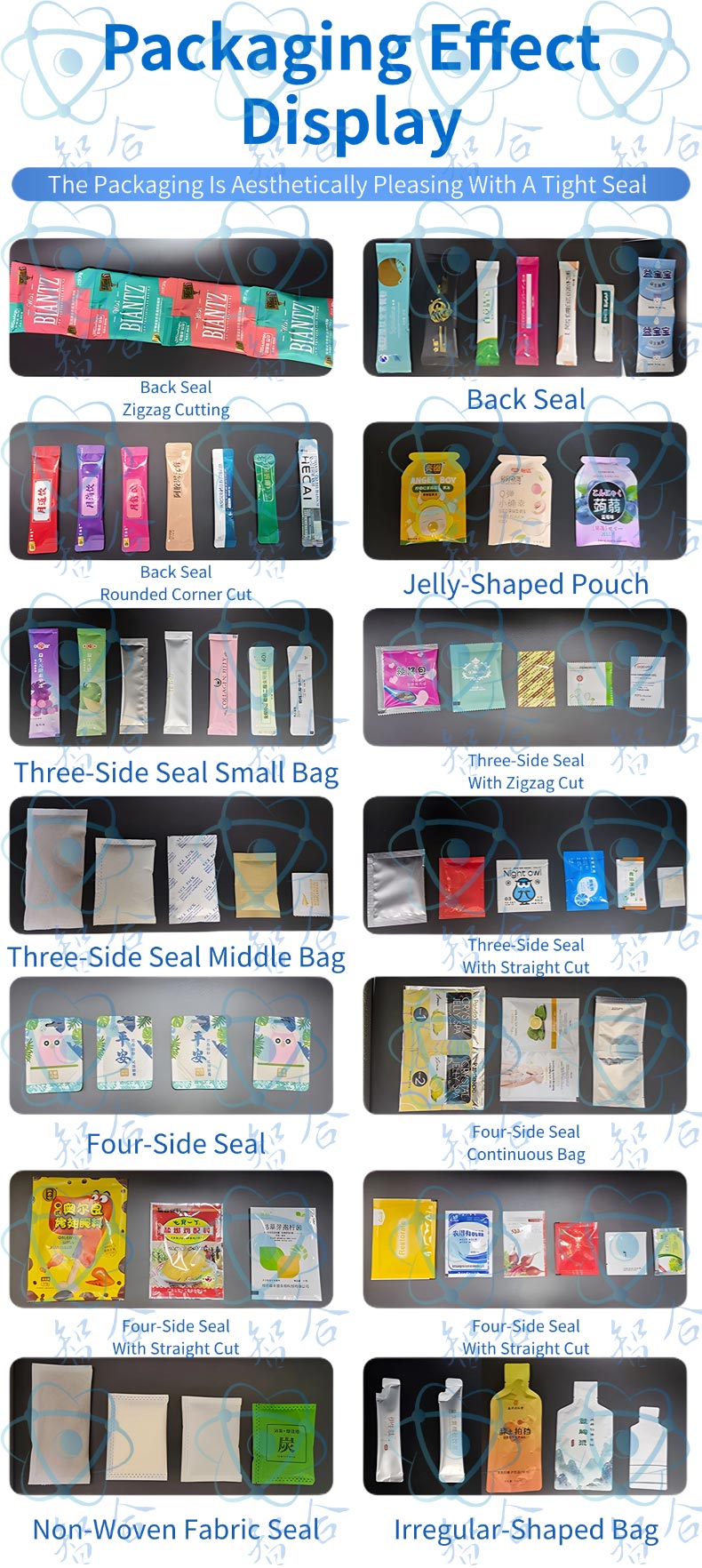

Adaptability: Suitable for packaging a wide range of liquid products, including soy sauce, vinegar, cooking wine, milk, beverages, cosmetics, and more, catering to diverse customer needs.

Working Principles

The working principles of the fully automatic liquid vertical packaging machine primarily encompass the following steps:

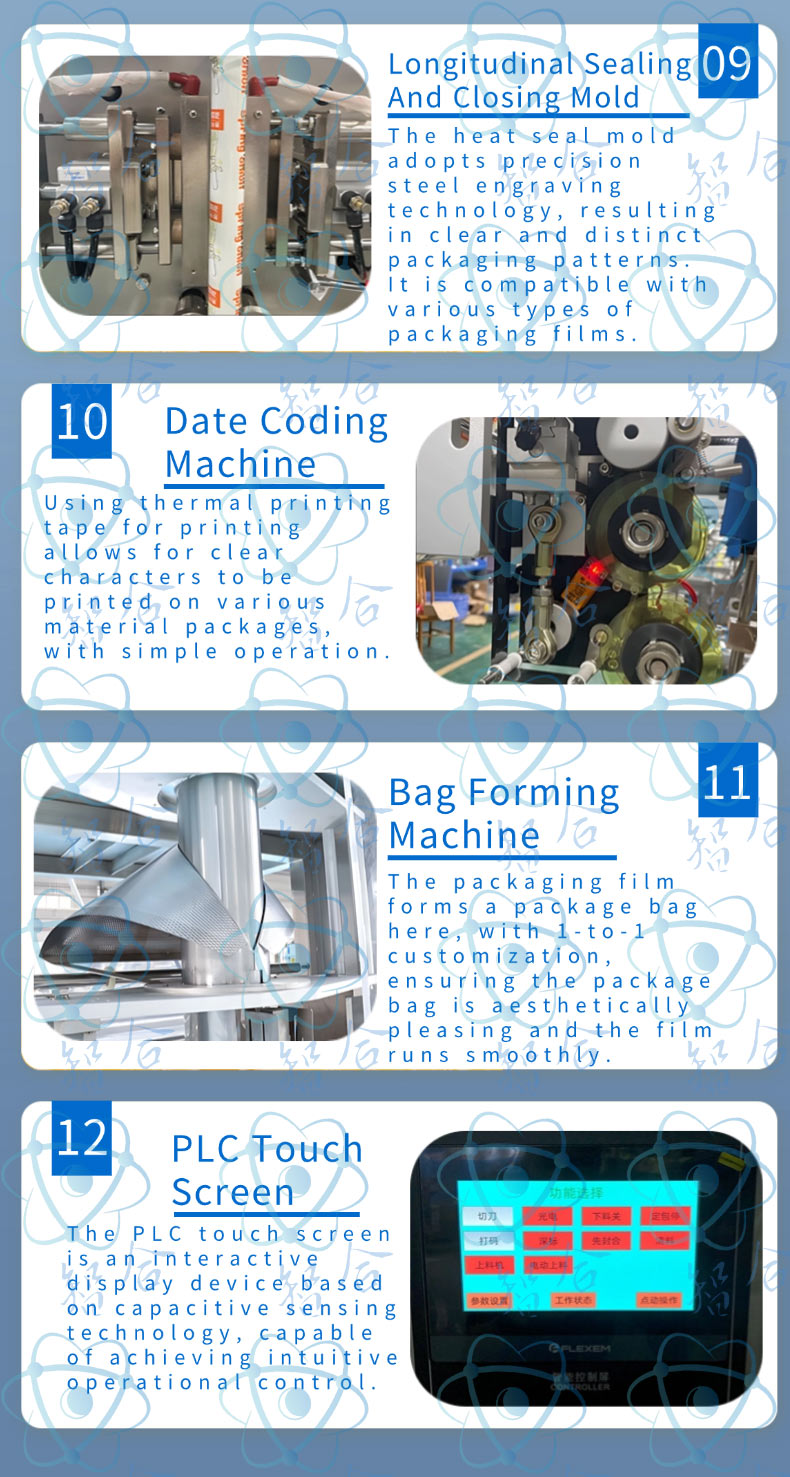

Film Feeding and Forming: The film is pulled from the film holder and precisely controlled by the film control motor, entering the film former for shaping into the desired bag form.

Liquid Filling: The liquid pump metering device extracts liquid from the 50-liter bulk hopper based on preset filling volumes and injects it into the formed bags through the discharge port. The filling volume is adjusted via the control panel of the liquid pump metering device.

Sealing Process: After filling, the bags enter the longitudinal and transverse sealing areas. Longitudinal sealing first seals the sides of the bag, followed by transverse sealing that cuts and seals the top or bottom, completing the packaging process.

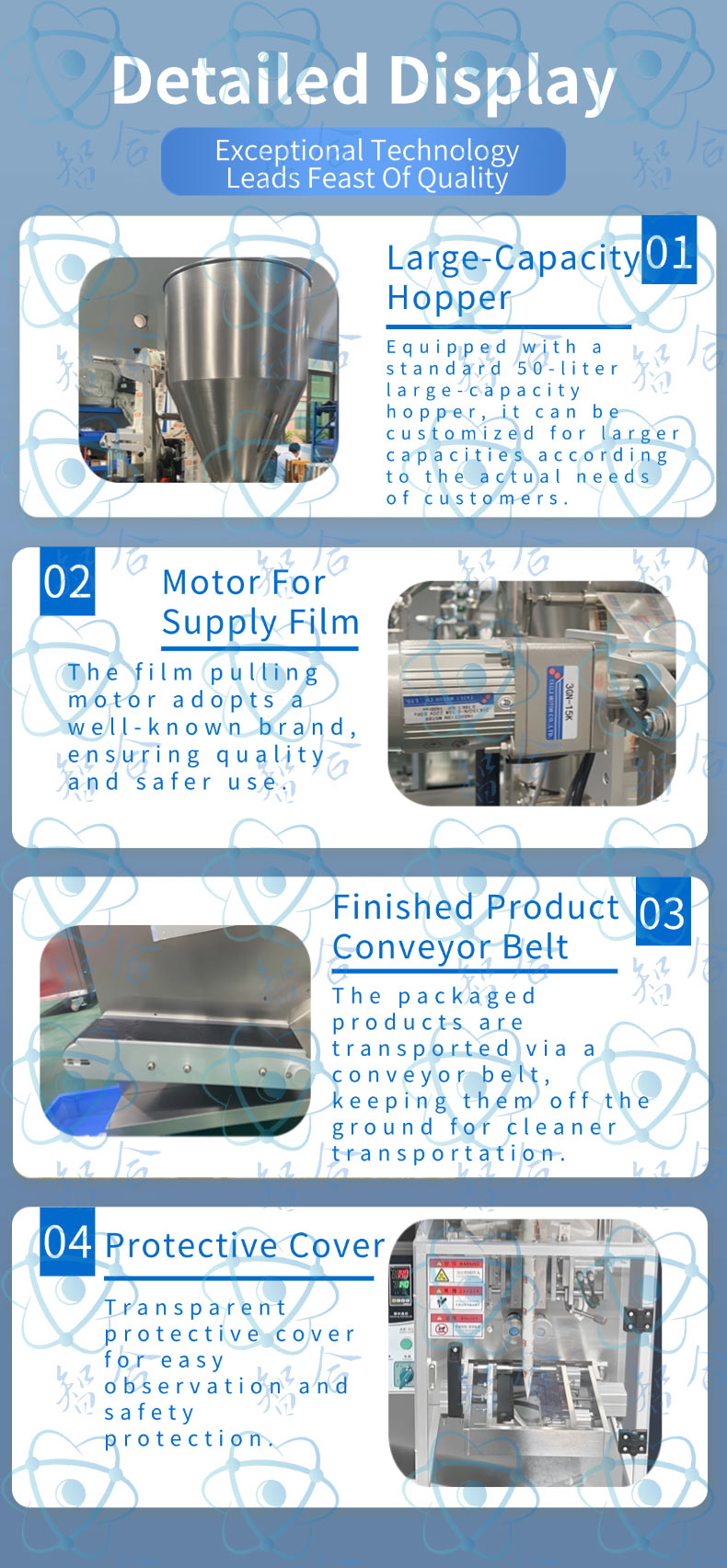

Cutting and Counting: The sealed bags are cut within the machine and counted by a counting device, facilitating subsequent packaging and transportation.

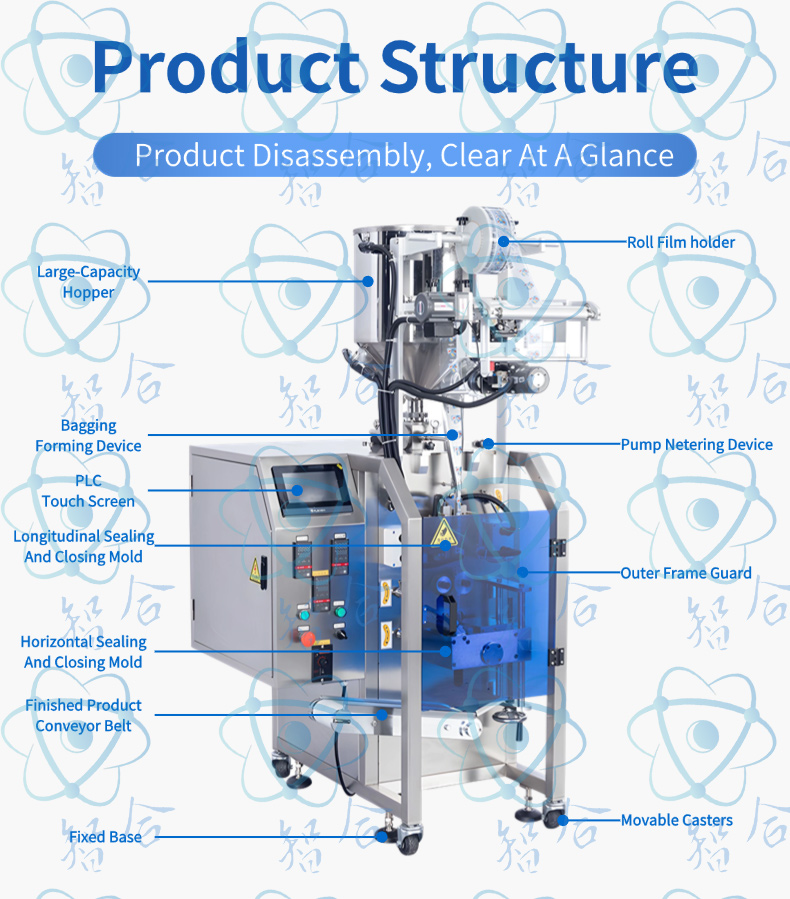

Detailed Component Explanation

50-liter Bulk Hopper: Stores the liquid raw materials for packaging, with a large capacity to meet the demands of continuous production over extended periods.

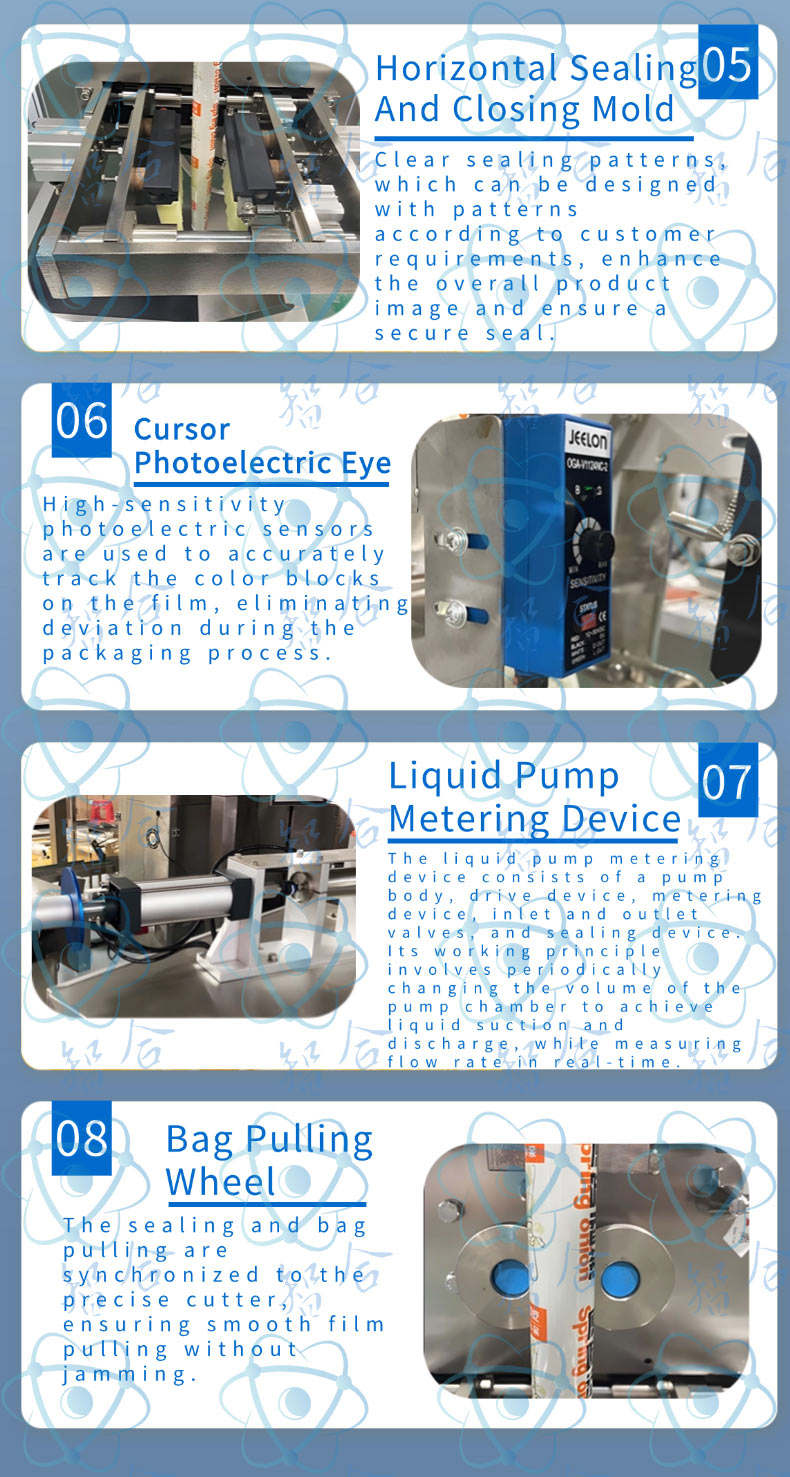

Film Holder: Holds and secures the film roll, ensuring smooth and continuous film feeding to the film former.

Film Control Motor: Precisely controls film feeding speed and tension, ensuring stability and consistency during film forming and packaging.

Filling Control Panel: Adjusts and controls the filling volume of the liquid pump metering device, ensuring accurate liquid quantities in each bag.

Liquid Pump Metering Device: Draws liquid from the hopper and transports it to the discharge port for precise filling.

Packaging Control Panel: Integrates various control buttons and displays, monitoring and adjusting equipment status, including film feeding, filling volumes, sealing temperatures, and other parameters.

Emergency Stop Switch: Quickly cuts off the equipment’s power in emergencies, ensuring operator safety.

Discharge Port: Connects the liquid pump metering device to the bags, ensuring accurate and leak-free liquid injection.

Mobile Casters: Facilitate equipment movement and installation, enhancing flexibility and convenience.

Film Former: Shapes the film into the desired bag form, preparing it for subsequent filling and sealing.

Longitudinal and Transverse Sealing: Respectively seal the sides and top/bottom of the bags, ensuring their seal integrity and completeness.

In conclusion, the fully automatic liquid vertical packaging machine, with its efficient, accurate, stable, and safe technical features, comprehensive components, and advanced working principles, plays a pivotal role in the liquid product packaging industry.