The fully automatic high-speed milk powder filling production line is a highly integrated production equipment specifically designed for filling powder products such as milk powder. This production line integrates various advanced technologies and equipment, realizing fully automated operations from empty can organization, cleaning and sterilization, precise filling to packaging and unloading. Based on the equipment assembly information provided, the following provides a detailed description of the technical features, working principles, and equipment assembly of this production line.

The fully automatic high-speed milk powder filling production line is a highly integrated production equipment specifically designed for filling powder products such as milk powder. This production line integrates various advanced technologies and equipment, realizing fully automated operations from empty can organization, cleaning and sterilization, precise filling to packaging and unloading. Based on the equipment assembly information provided, the following provides a detailed description of the technical features, working principles, and equipment assembly of this production line.

Technical Features

High Automation: The entire production line adopts a PLC control system combined with a touch screen human-machine interface, achieving fully automated operations and significantly enhancing production efficiency and product quality.

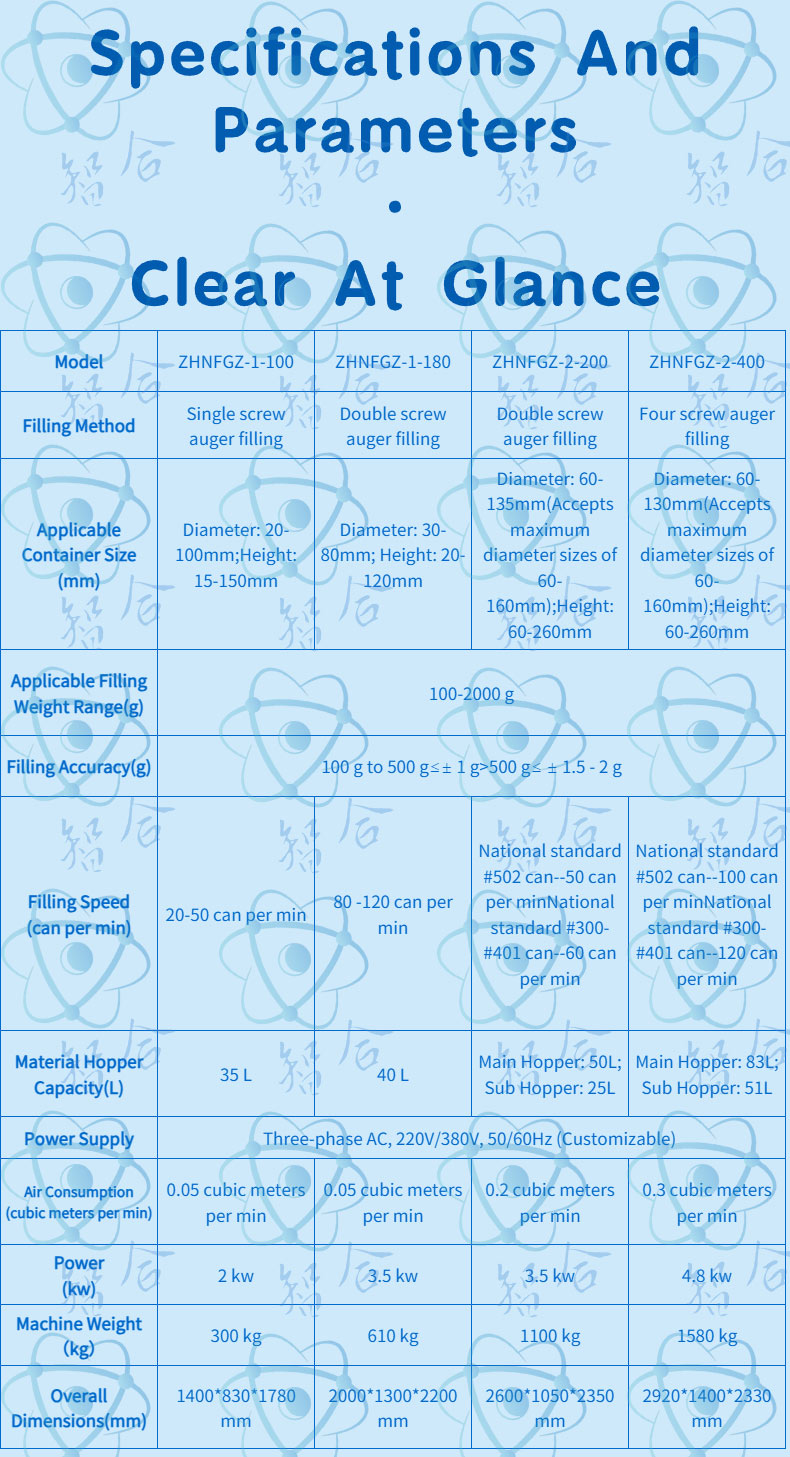

High-Precision Filling: It employs high-precision electronic weighing scales and servo motor-driven filling systems to ensure that the filling volume of each can of milk powder is precise, with an error rate controlled within ±1-2g.

Hygiene and Safety: All equipment parts in contact with materials are made of stainless steel with polished inner walls, facilitating easy cleaning and disinfection, meeting GMP and food hygiene standards.

Efficiency and Energy Saving: Employing variable frequency speed regulation technology, it flexibly adjusts equipment operating speeds based on production demands while optimizing energy management to reduce energy consumption.

Working Principles

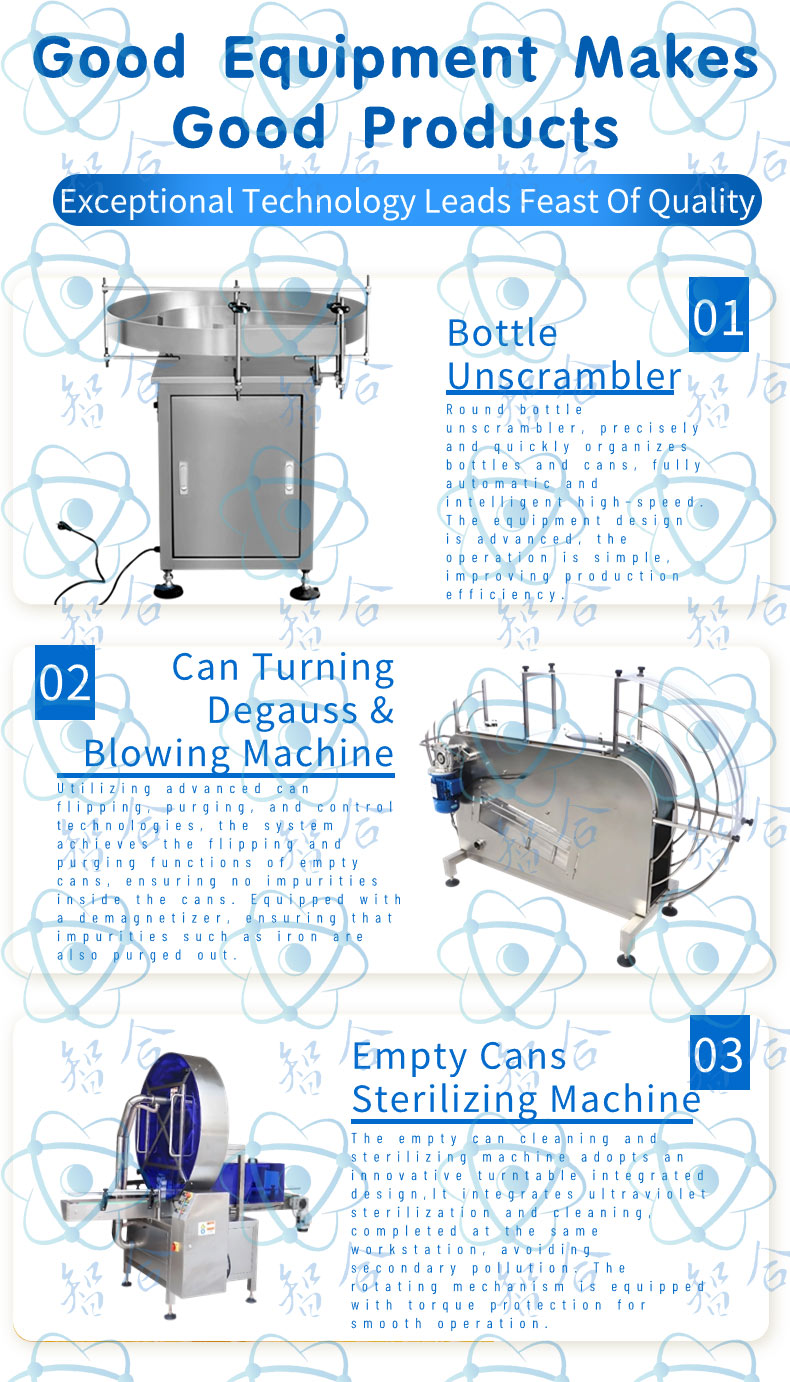

Can Organizer: Initially, empty cans are organized by the can organizer to ensure neat alignment, facilitating subsequent processes.

Can Inverter, Demagnetizer, and Blower: Empty cans enter the inverter, demagnetizer, and blower, where they are flipped, blown clean, and demagnetized to ensure no impurities remain inside.

Ultraviolet Sterilization Machine for Empty Cans: Cleaned cans proceed to the ultraviolet sterilization machine, where UV light eradicates residual microorganisms inside, ensuring sterility.

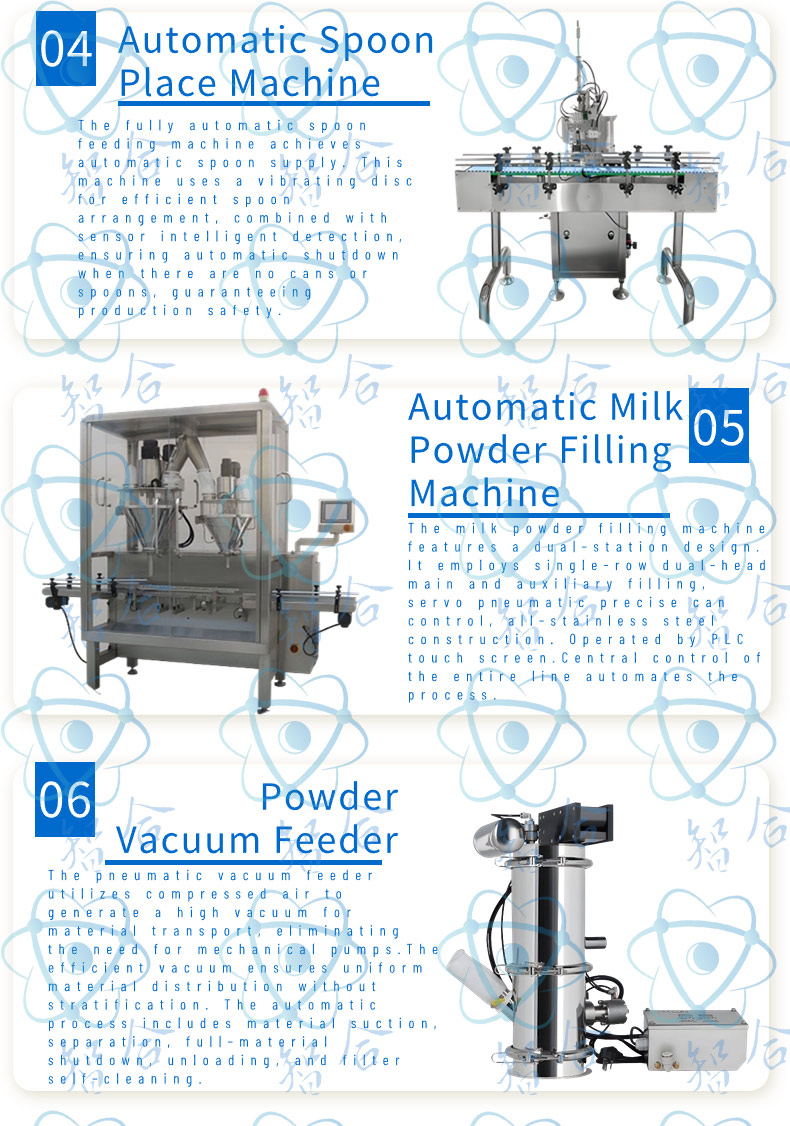

Spoon Feeder (Optional): Some production lines include a spoon feeder, depositing spoons into cans before filling for consumer convenience.

Milk Powder Filler: Preprocessed empty cans enter the milk powder filler, where high-precision electronic weighing scales and servo motor-controlled filling systems achieve precise filling.

Powder Vacuum Loader: The milk powder is transferred from the storage tank to the filler via a vacuum loader, ensuring continuous and stable material feeding.

Can Body Cleaner: Filled cans enter the can body cleaner, where the exterior is cleaned to remove any adhering dust or impurities.

Inkjet Printer: Date of production, batch numbers, and other information are printed on can bodies for traceability and management.

Can Turner: Inverted cans facilitate subsequent processes.

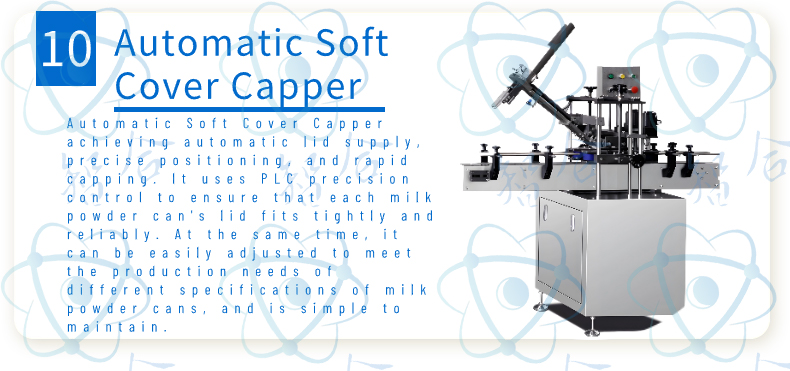

Soft Cap Crimper: Finally, cans enter the soft cap crimper, where caps are crimped to ensure product seal integrity.

Equipment Assembly

Equipment assembly for the entire production line must strictly follow design drawings and installation specifications to ensure seamless integration and smooth operation. Specific assembly steps include:

Base Installation: First, install the production line’s base frame and support structures, ensuring stability and reliability.

Equipment Installation: Following the process flow, sequentially install the can organizer, can inverter, demagnetizer, blower, ultraviolet sterilization machine, spoon feeder (if equipped), milk powder filler, powder vacuum loader, can body cleaner, inkjet printer, can turner, and soft cap crimper.

Electrical Connection: Complete electrical wiring connections for all equipment, including the PLC control system, touch screen human-machine interface, motor drives, etc.

Debugging and Operation: After installation, conduct comprehensive debugging and operational checks to verify functionality and adjust equipment parameters to optimal settings.

Acceptance and Delivery: Upon successful debugging, proceed with acceptance and delivery, providing operational training and after-sales services.

In summary, the fully automatic high-speed milk powder filling production line plays a vital role in the production of milk powder and other powder products due to its efficiency, precision, and hygiene features.