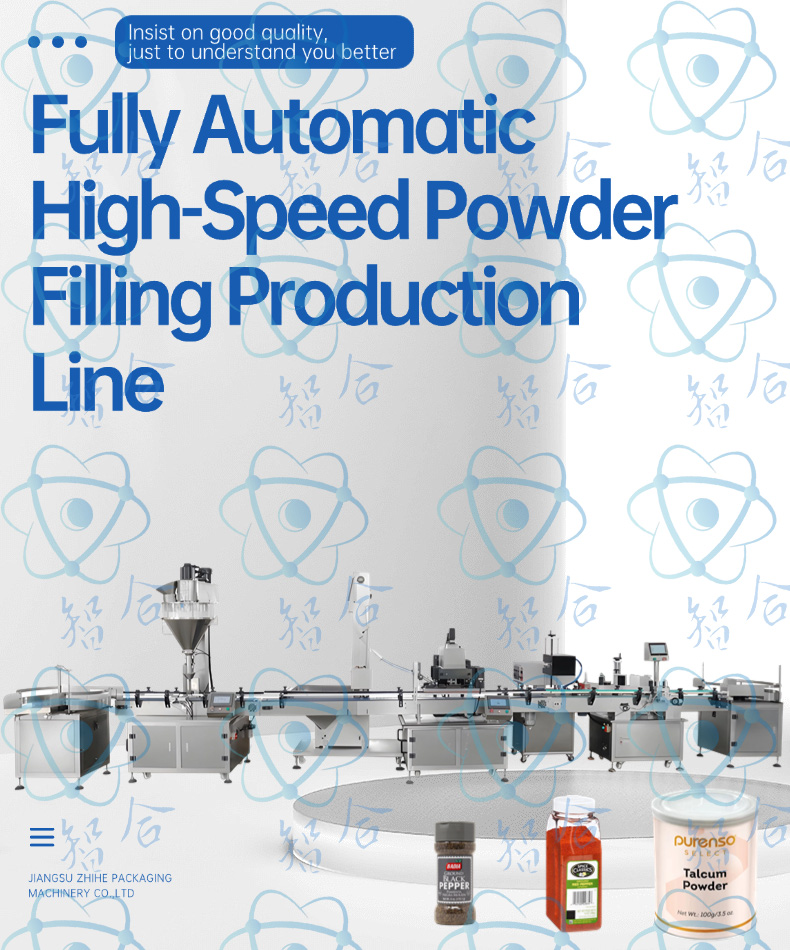

The fully automatic seasoning powder filling production line is a highly automated production equipment specifically designed for the filling operation of seasoning powders such as chicken essence, MSG, pepper powder, chili powder, and more. This production line integrates multiple functional modules, leveraging precise mechanical transmission and intelligent control systems to achieve full automation from raw material feeding to final product packaging. Below is a detailed description of the fully automatic seasoning powder filling production line:

The fully automatic seasoning powder filling production line is a highly automated production equipment specifically designed for the filling operation of seasoning powders such as chicken essence, MSG, pepper powder, chili powder, and more. This production line integrates multiple functional modules, leveraging precise mechanical transmission and intelligent control systems to achieve full automation from raw material feeding to final product packaging. Below is a detailed description of the fully automatic seasoning powder filling production line:

- System Composition

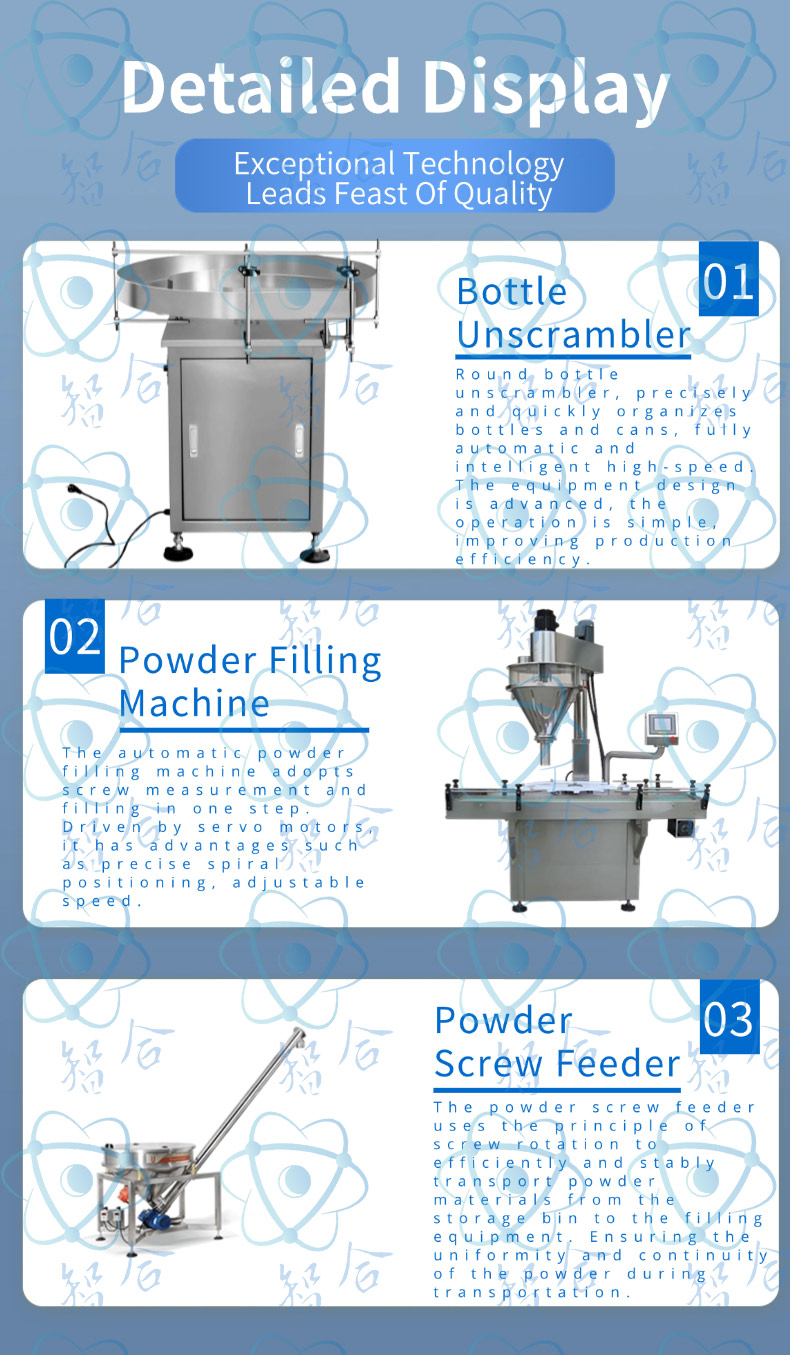

- Screw Feeder

- Function: To quantitatively and continuously convey pre-processed seasoning powder raw materials into the hopper of the filling machine.

- Features: Utilizes the principle of screw rotation, adjusting the screw’s speed and depth to control the feeding amount, ensuring accurate filling.

- Filling System

- Function: Precisely fills seasoning powder into packaging containers (e.g., bottles, bags).

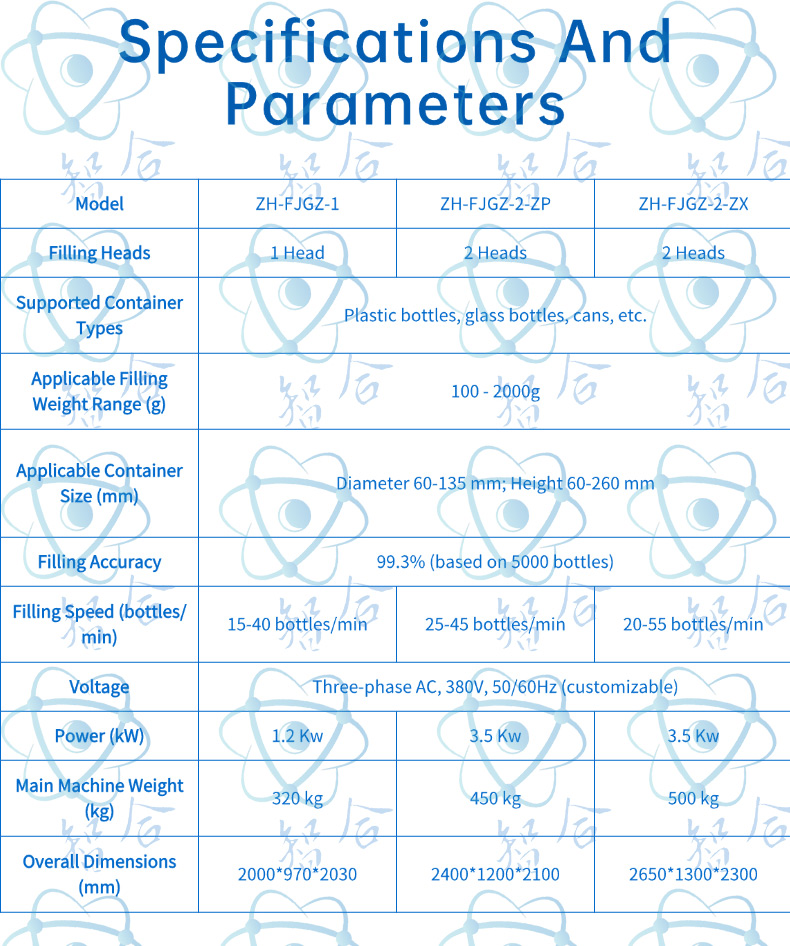

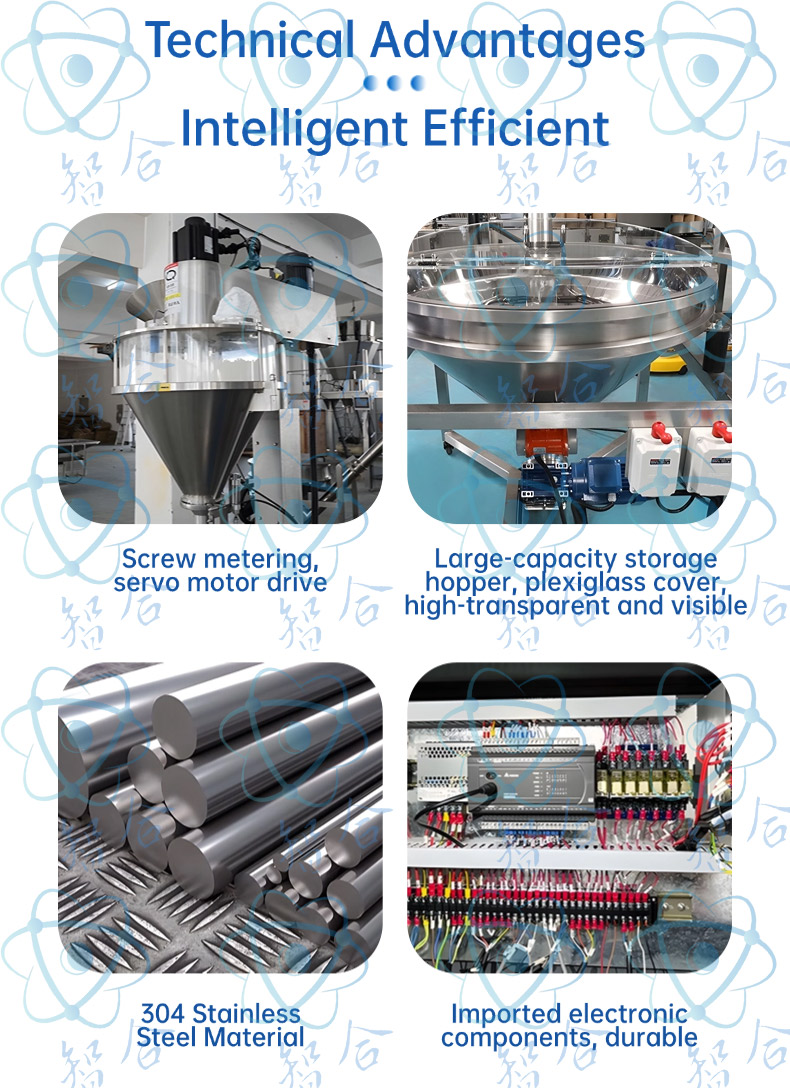

- Equipment: Fully automatic powder filling machine, employing screw metering combined with servo motor drive, advanced sensors, and control systems for automatic metering and filling.

- Features:

- High filling accuracy with minimal error.

- Fast filling speed to meet high-speed production demands.

- Supports various packaging specifications and materials.

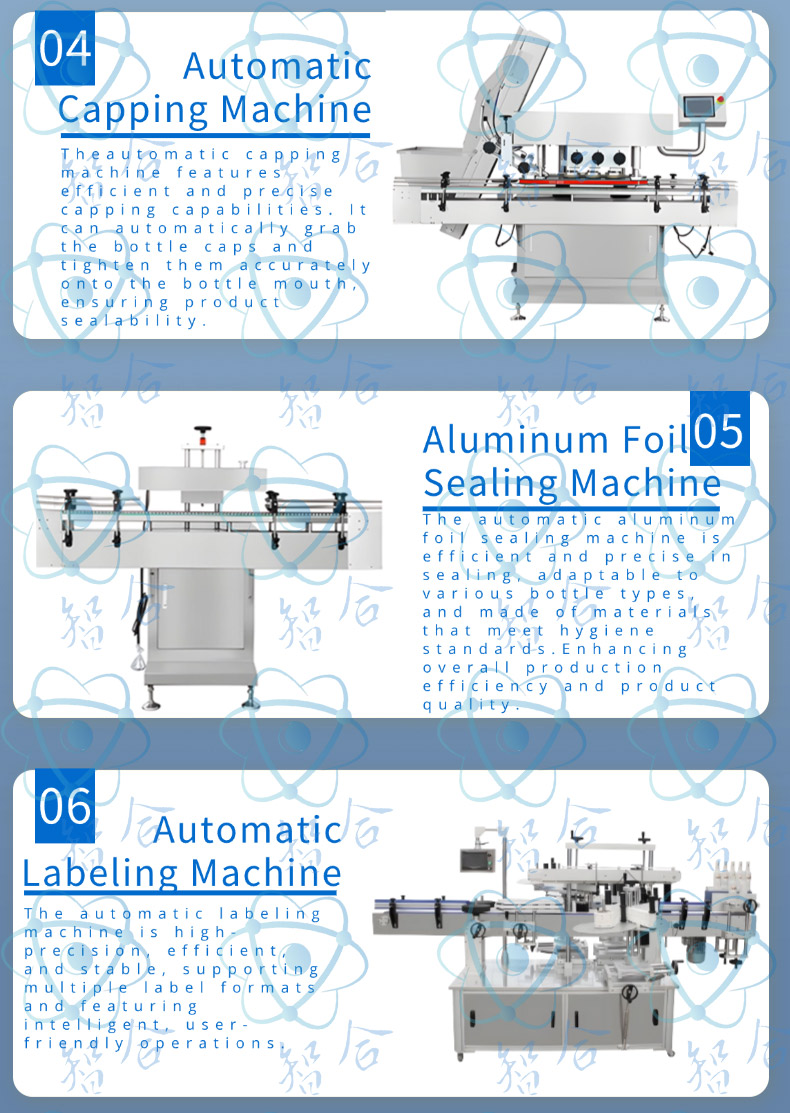

- Sealing System

- Function: Seals the filled packaging containers to ensure product sealing and shelf life.

- Equipment: Automatic capping machines, aluminum foil sealing machines, etc.

- Features:

- Tight sealing with no leakage.

- Supports multiple sealing methods and materials.

- Conveyor System

- Function: Transports packaged products from the filling line to the next process or finished product area.

- Equipment: Conveyor belts, elevators, etc.

- Features:

- Smooth transportation without jolting.

- Adjustable conveying speed and direction based on production needs.

- Control System

- Function: Monitors and adjusts the operating status of the entire production line in real-time, ensuring process stability and efficiency.

- Features:

- Uses PLC and touch screen control for easy and intuitive operation.

- Equipped with fault diagnosis and early warning functions to identify and resolve issues promptly.

- Can connect with upper computers or MES systems for real-time monitoring and tracing of production data.

- Main Advantages

- Increased Production Efficiency: The automated production process significantly enhances production speed, reducing manual intervention and waiting time.

- Improved Product Quality: Precise metering and filling technology ensure product consistency and high quality.

- Reduced Production Costs: Lowers labor costs and material waste, enhancing production efficiency and resource utilization.

- Enhanced Production Flexibility: Quickly adjusts equipment parameters and production line configurations based on production demands.

- Elevated Corporate Image: The automated production line showcases a company’s technological prowess and production capabilities, contributing to brand image enhancement and market competitiveness.