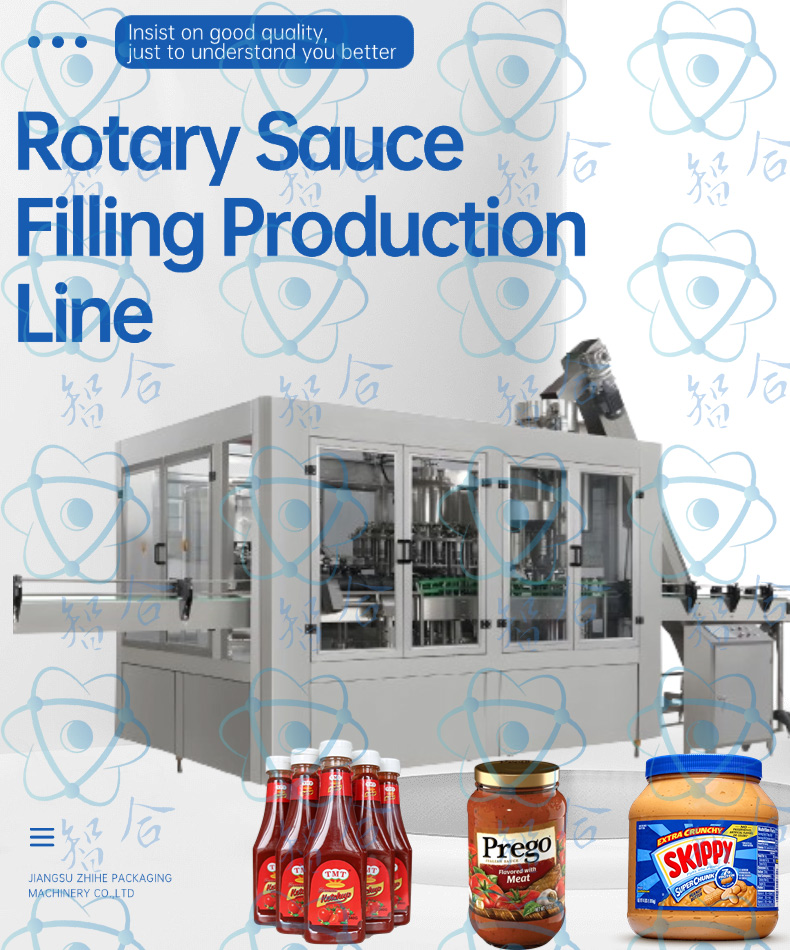

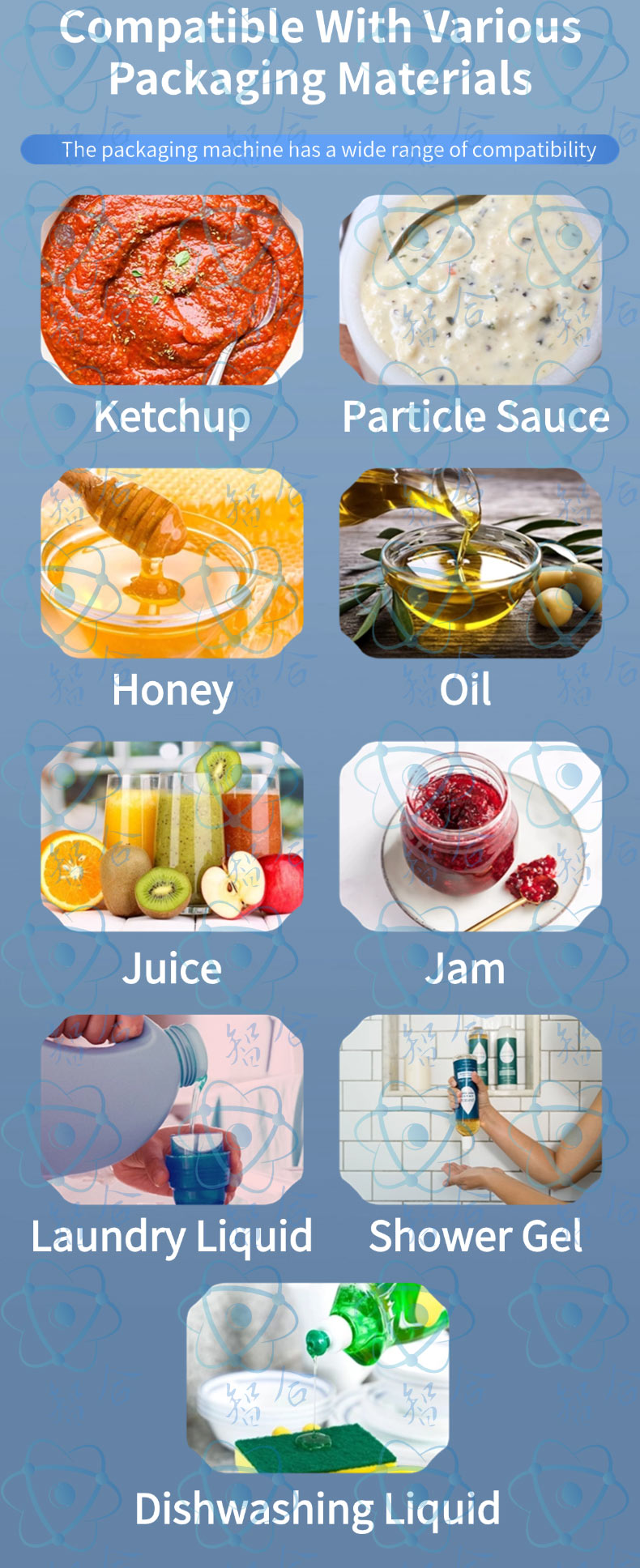

The rotary sauce filling production line is specifically designed to meet the demands of high-capacity production environments with uniform packaging materials. Its compact rotary design optimizes space utilization and enhances overall production efficiency and flexibility. This production line also adheres to the concept of high integration and automation, ensuring efficient, hygienic, and superior-quality sauce filling processes. Here is a detailed description of the rotary sauce filling production line:

The rotary sauce filling production line is specifically designed to meet the demands of high-capacity production environments with uniform packaging materials. Its compact rotary design optimizes space utilization and enhances overall production efficiency and flexibility. This production line also adheres to the concept of high integration and automation, ensuring efficient, hygienic, and superior-quality sauce filling processes. Here is a detailed description of the rotary sauce filling production line:

- Automatic Bottle Sorting and Conveying System

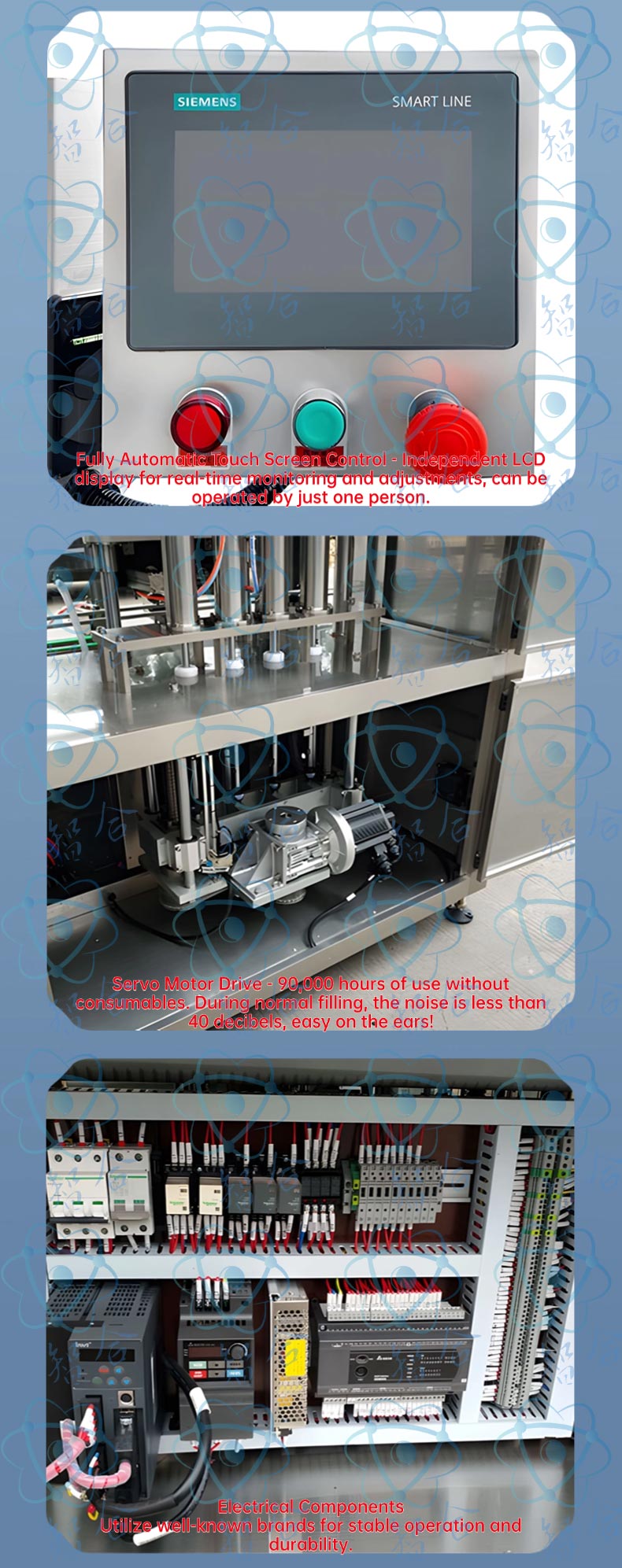

At the beginning of the production line, an advanced automatic bottle sorting machine is equipped. Utilizing vibratory discs, conveyor belts, and intelligent recognition technology, it automatically arranges empty bottles and feeds them into the rotary conveying track at a stable speed. This system ensures that each bottle enters subsequent processes accurately and orderly, laying the foundation for efficient filling. - Fully Automatic Three-in-One Sauce Filling Machine

The core of the rotary production line lies in its integrated fully automatic three-in-one sauce filling machine. This machine combines internal and external water/air bottle washing, high-temperature drying and sterilization, and filling functions into one, significantly simplifying the production process. Bottles move sequentially along the rotary track through cleaning, drying, and filling zones, achieving one-stop processing. This not only enhances production efficiency but also reduces equipment footprint and labor costs.

Cleaning & Drying: High-pressure water jets or gases combined with hot air circulation or far-infrared heating technology thoroughly clean and dry bottles, ensuring a sterile state.

Filling: A high-precision filling system ensures accurate sauce volume in each bottle, meeting strict quality control requirements.

Automatic Cap Sorting & Capping System: Filled bottles continue along the rotary track into the automatic cap sorting and capping system. This system automatically organizes and distributes caps to each bottle, followed by precise mechanical arms or rotating heads screwing the caps tightly onto bottle necks, ensuring sealing performance and preventing sauce leakage.

- Fully Automatic Labeling & Inkjet Printing System

Bottles then enter the labeling and inkjet printing area. The automatic labeling machine precisely affixes pre-printed labels to designated positions on the bottles, while the inkjet printer prints production dates, batch numbers, and other information on bottle bodies or caps, enhancing product traceability and market appeal. - Fully Automatic Sleeve Labeling & Shrink Wrapping System (Optional)

Some rotary production lines are also equipped with automatic sleeve labeling and shrink wrapping machines. The sleeve labeling machine applies transparent shrink film over labeled bottles, and the shrink wrapping machine heats the film, causing it to tightly wrap around the bottle bodies, enhancing product appearance and protection. - Fully Automatic Carton Opening, Packing, & Sealing System (Optional)

Bottles finally enter the automatic carton opening, packing, and sealing system. This system intelligently recognizes bottle quantities and arrangements, automatically opening cartons, arranging bottles inside, and sealing the cartons to form the final product packaging. - Robotic Palletizing & Warehousing System (Optional)

At the end of the production line, the robotic palletizing system operates efficiently, transporting filled cartons to designated locations and stacking them according to preset arrangements. This reduces manual intervention and improves warehouse efficiency and storage space utilization.

In summary, the rotary sauce filling production line, with its compact design, efficient processes, and integrated machinery configuration, provides an ideal solution for high-capacity production environments with uniform packaging materials. It empowers enterprises to enhance production efficiency, product quality, and market competitiveness.