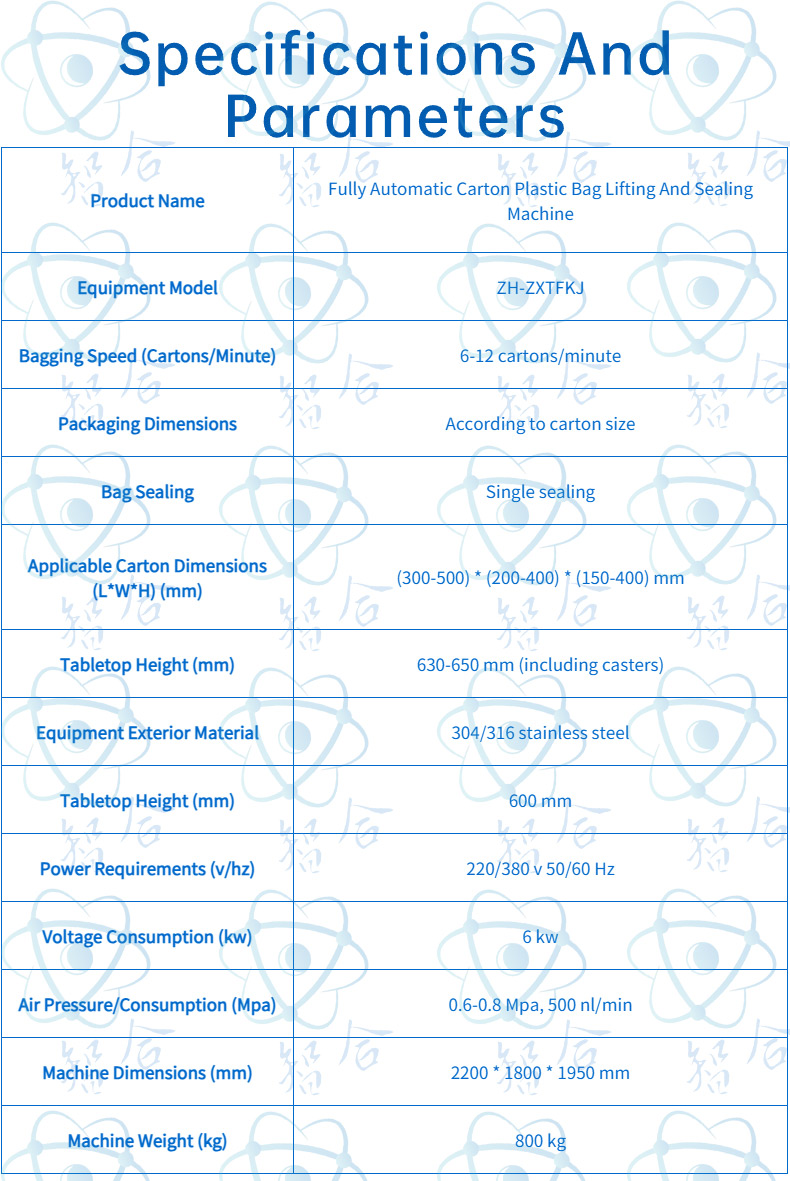

Fully Automatic Carton Plastic Bag Lifting And Sealing Machine – Detailed Technical Description

Fully Automatic Carton Plastic Bag Lifting And Sealing Machine – Detailed Technical Description

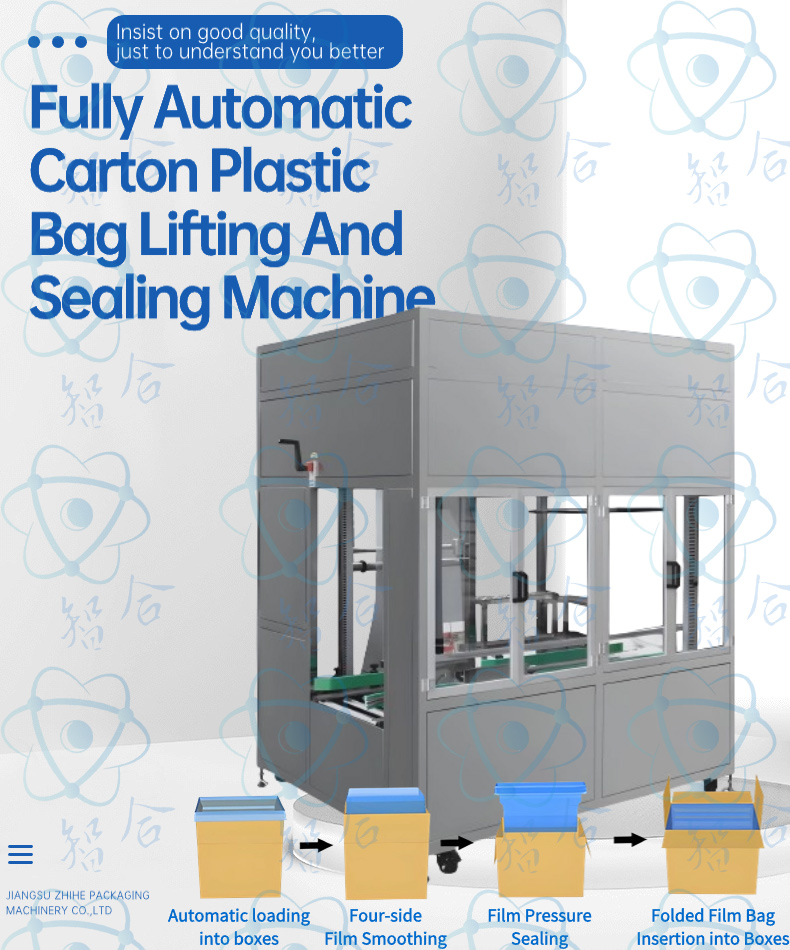

The Fully Automatic Carton Plastic Bag Lifting And Sealing Machine is a crucial piece of automated packaging line equipment, particularly suitable for carton products requiring inner bag sealing. Its core function is to automatically complete the processes of lifting the plastic bag inside a carton that has already been filled with materials, heat-sealing the bag mouth, and folding and flattening the excess bag opening. This prepares the carton for subsequent carton sealing processes. This equipment is widely used in industries requiring moisture-proof, dust-proof, and freshness-preserving packaging, such as chemical raw materials, food ingredients, and pharmaceutical intermediates.

Based on the process you described, the design principles and mechanical structure revolve around the key steps: Bag Lifting → Top Sealing → Folding and Flattening.

I. Design Principles (Inner Bag Sealing Type)

The core design of the Fully Automatic Carton Plastic Bag Lifting And Sealing Machine lies in efficiently, accurately, and reliably completing the sealing of the inner bag within the carton, seamlessly integrating with upstream and downstream processes. Its design principles are mainly reflected in the following aspects:

1. Flow-based Automated Operation Principle:

The equipment is designed for a fully automated process, seamlessly docking with upstream carton erecting machines, case packers, and downstream case sealing machines to achieve continuous, high-efficiency production.

It strictly follows the process sequence of Carton Arrival Detection → Bag Lifting Mechanism Action → Top Sealing → Folding and Flattening → Finished Product Output, requiring no manual intervention.

2. Precise Bag Lifting and Bag Mouth Control Principle:

Reliable Bag Lifting Mechanism: It must be able to stably and reliably lift the plastic bag opening inside the carton completely and without damaging the bag body. During the bag lifting process, it is necessary to ensure the bag mouth is opened for subsequent sealing.

Bag Mouth Opening and Positioning: After lifting the bag mouth, it needs to be effectively opened and positioned at the sealing station to ensure accurate sealing position and consistent sealing quality.

3. Efficient and Reliable Heat Sealing Principle:

Heat Sealing Quality Assurance: The sealing mechanism must provide stable and controllable heat and pressure to ensure the plastic bag mouth is heat-sealed firmly and with good sealing performance, meeting the sealing requirements of product packaging (such as moisture-proof, leak-proof, etc.).

Adaptability to Different Bag Materials: The equipment should be able to adapt to plastic inner bags of different materials and thicknesses, achieving the best sealing effect through parameter adjustments (such as temperature, pressure, and time).

Efficient Sealing: The sealing process is fast and efficient, without affecting the overall production line takt time.

4. Precise Folding and Flattening Principle:

Neat Bag Mouth Folding: The excess bag opening portion needs to be precisely folded by the mechanism, either inwards or to both sides, ensuring the neatness and consistency of the folding.

Flattening Effect: The folded bag mouth needs to be flattened, reducing the height of the carton top to create a flat surface for the subsequent carton sealing process, ensuring sealing effectiveness and aesthetics.

No Damage to Bag Body: The folding and flattening process needs to avoid causing damage to the sealed portion or the bag body, ensuring the sealing performance is not compromised.

5. Stable, Reliable and Easy Maintenance Principle:

Equipment Operation Stability: The equipment needs to operate stably for long periods with a low failure rate, ensuring the continuity and efficiency of the production line.

Easy Operation and Maintenance: The operation interface should be user-friendly and easy to understand for parameter setting and equipment status monitoring; the mechanical structure design should consider the convenience of maintenance and upkeep to reduce downtime.

Safety Protection: The equipment must be equipped with necessary safety protection devices to ensure the safety of operators.

II. Mechanical Structure Composition

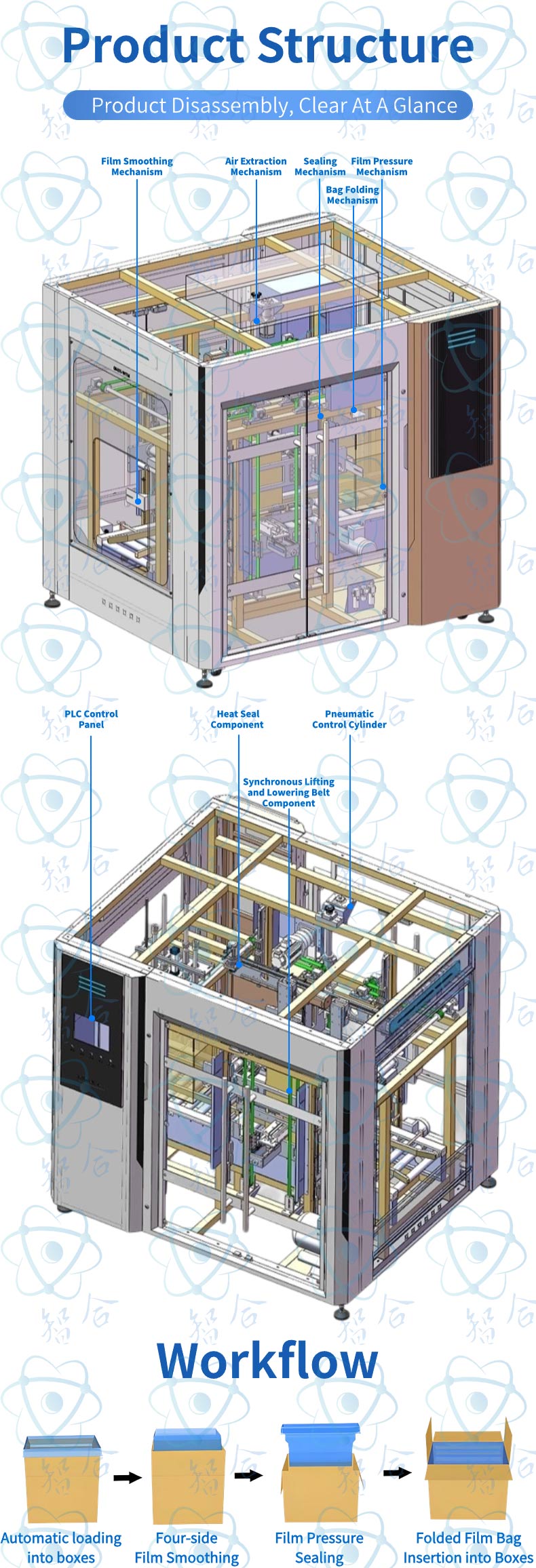

The mechanical structure of the Fully Automatic Carton Plastic Bag Lifting And Sealing Machine revolves around the three core actions of Bag Lifting, Sealing, and Folding & Flattening, and is composed of the following main parts:

1. Carton Input and Positioning System:

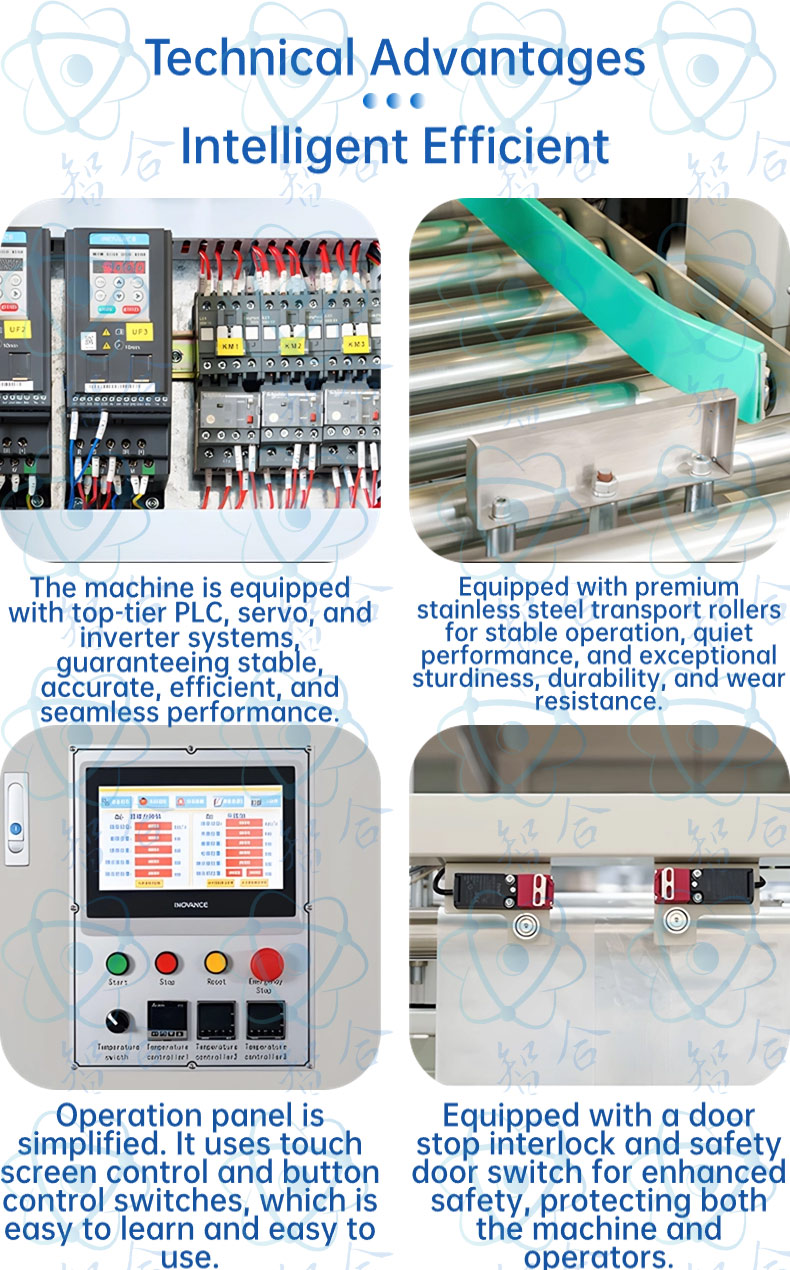

Carton Conveying Mechanism: Typically uses roller conveyor lines or chain conveyor lines to carry cartons from the upstream case packer and smoothly transport them to the bag lifting and sealing station.

Carton Arrival Detection: Sensors (such as photoelectric sensors and proximity sensors) are used to detect whether the carton has reached the predetermined station, triggering subsequent mechanism actions.

Carton Positioning Mechanism: During the bag lifting and sealing process, it may be necessary to precisely position the carton. For example, cylinder-driven baffles or clamping mechanisms are used to ensure the carton position is stable.

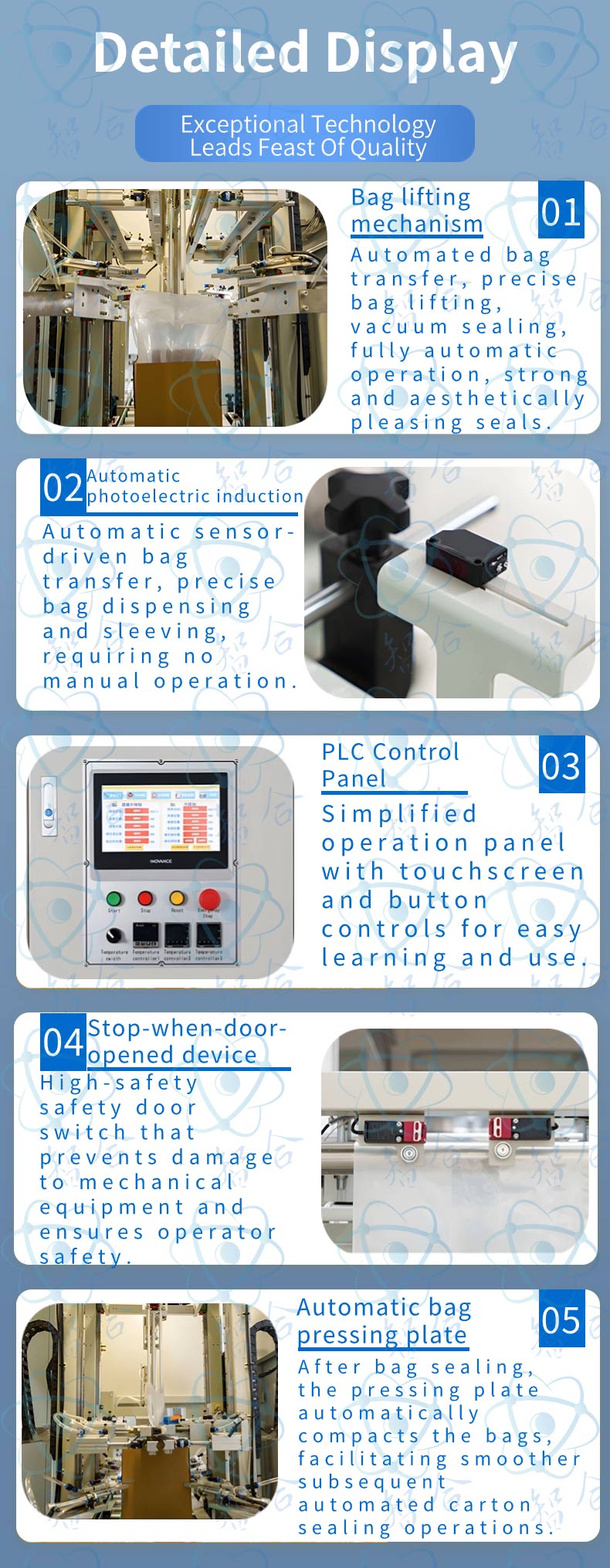

2. Bag Lifting Mechanism:

Gripper-type Bag Lifting Mechanism: Employs mechanical grippers or claws to reach into the carton from above, grasp the edge of the plastic bag opening, and then lift it upwards. The design of the grippers needs to consider adaptability to bag openings of different materials and thicknesses, as well as the reliability and stability of the gripping.

Vacuum Suction Cup Bag Lifting Mechanism: Utilizes vacuum suction cups to adsorb the surface of the plastic bag opening and then lift it upwards. Suitable for plastic bags with relatively flat bag opening surfaces. The number and distribution of suction cups need to be designed according to the bag opening size and weight.

Air Blowing Assisted Opening Mechanism (Optional): Before bag lifting, an air blowing device can be used to blow air into the carton to assist in opening the bag mouth, making it easier for the bag lifting mechanism to grab.

3. Bag Mouth Opening and Positioning Mechanism:

Opening and Clamping Mechanism: After the bag lifting mechanism lifts the bag mouth, a clamping mechanism (such as pneumatic finger grippers, mechanical clamps) is used to clamp the bag mouth from both sides or all around, opening and fixing it.

Bag Mouth Shaping Mechanism (Optional): For cases where the bag mouth shape is irregular, it may be necessary to add a shaping mechanism, such as using guide plates or rollers to organize the bag mouth, making it flat and easy for sealing.

4. Top Sealing Mechanism:

Heat Sealing Mechanism: This is the core component, and the following heat sealing methods are typically used, allowing customers to choose as needed:

Ultrasonic Sealing: Utilizes ultrasonic energy to instantly fuse the plastic bag mouth, with fast sealing speed, high strength, and good sealing performance. Suitable for occasions with extremely high sealing requirements.

Sealing Knife/Sealing Belt: Heating elements that directly contact the plastic bag mouth. The material and shape are selected according to the sealing method and bag material characteristics.

Pressure Mechanism: Provides the pressure required during sealing, typically using cylinder-driven pressure plates or pressure rollers to ensure the sealing knife/sealing belt is in close contact with the bag mouth to achieve firm sealing.

Temperature Control System: Precisely controls the sealing temperature to ensure the stability and consistency of the sealing quality.

5. Folding and Flattening Mechanism:

Folding Mechanism: Responsible for folding the excess bag opening portion. Common folding methods include:

Two-Side Inward Folding: Uses folding plates or folding arms to fold both sides of the bag mouth inwards towards the inside of the carton.

Multiple Folding (Z-fold, etc.): For cases with longer bag openings, multiple folding methods may be used to reduce the volume after folding.

Flattening Mechanism: After folding is complete, a pressure plate, pressure roller, or belt pressing mechanism is used to flatten the folded bag mouth, making it adhere closely to the carton top and remain flat.

6. Output System:

Finished Product Output Conveyor Line: Transports cartons that have completed inner bag sealing and folding & flattening to the subsequent case sealing machine station.

7. Control System:

PLC (Programmable Logic Controller): Serves as the control core of the equipment, controlling the overall equipment operation logic and motion coordination.

HMI (Human-Machine Interface): Used for operation parameter setting, equipment status monitoring, fault alarm display, etc.

Sensor System: Various sensors (such as photoelectric sensors, proximity sensors, temperature sensors, etc.) monitor the equipment operating status and parameters in real time and feed data back to the PLC to achieve closed-loop control.

Drive System: Includes motors, cylinders, servo motors, etc., driving various mechanical mechanisms for precise motion.

8. Safety Protection System:

Safety Guard/Door: Isolates hazardous areas to ensure operator safety.

Emergency Stop Button: Quickly stops equipment operation in emergencies.

Overload Protection: Protects motors and other drive components to prevent equipment damage.

Summary

The Fully Automatic Carton Plastic Bag Lifting And Sealing Machine is a highly integrated automation equipment system. It combines precision mechanical design, advanced control technology, and reliable heat sealing technology to achieve efficient and stable sealing and arranging of carton inner bags. Understanding its design principles and mechanical structure composition helps users better select, use, maintain, and optimize the equipment, improve production efficiency and packaging quality, and meet the inner bag sealing packaging needs of various industries.