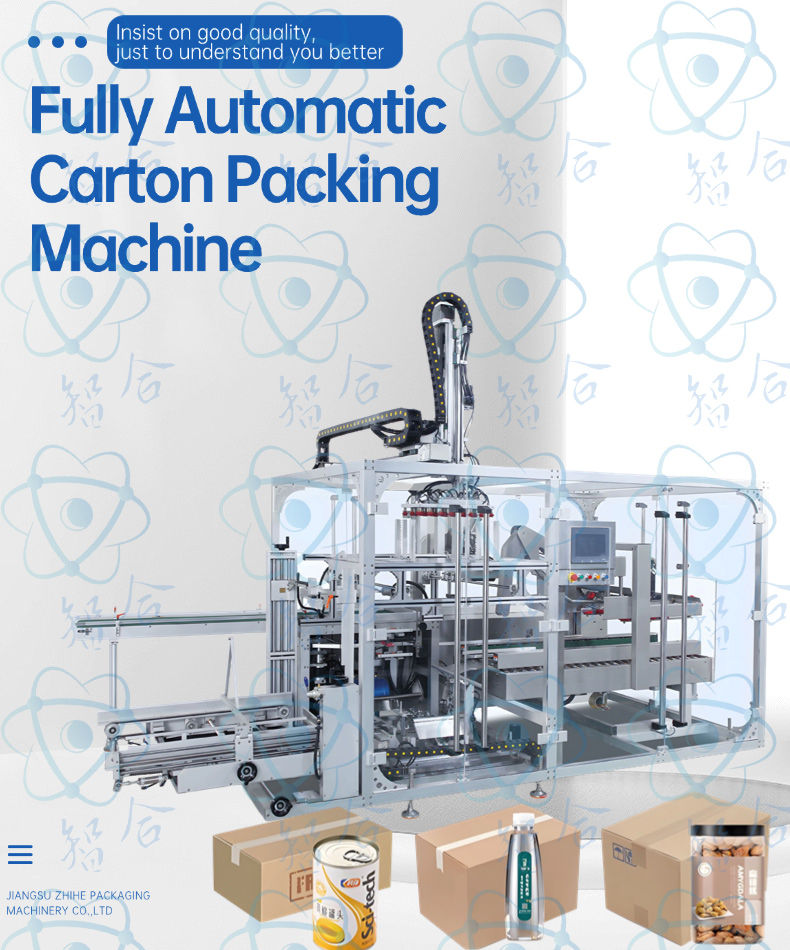

Automatic Grab-Type Case Packer

Automatic Grab-Type Case Packer

I. Product Overview

The Automatic Grab-Type Case Packer is an efficient and intelligent packaging device meticulously developed based on the advantages of various domestic and international case packing technologies. Specifically designed for packaging containers such as PET bottles, plastic bottles, glass bottles, two-piece cans, and three-piece cans, it can automatically organize and accurately pack these containers into cardboard (plastic) boxes. The machine features a compact structure and innovative design, with key components utilizing high-quality imported parts, ensuring an excellent cost-performance ratio and stable operating performance. It is widely used in industries such as beer, beverages, food, chemicals, and pharmaceuticals, and is particularly suitable for assembly line operations. It is portable and easy to integrate into existing production lines.

II. Technical Features

Operational Reliability:

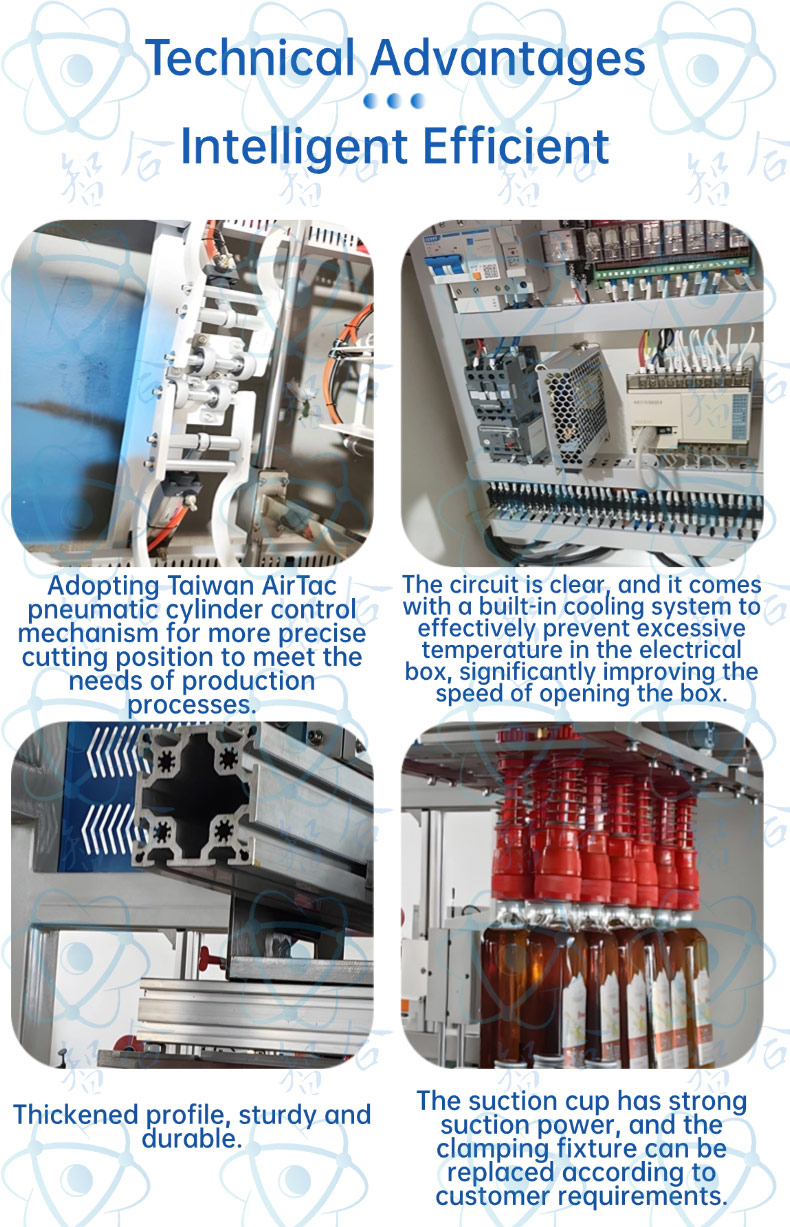

Adopts a single-channel box feeding design, utilizing a gripping and releasing mechanism of the grab head through charging and discharging air.

Precise coordination among mechanical operation, pneumatic control, and the electronic control system ensures accurate and reliable extraction of bottles from boxes, reducing breakage rates.

Operational Stability:

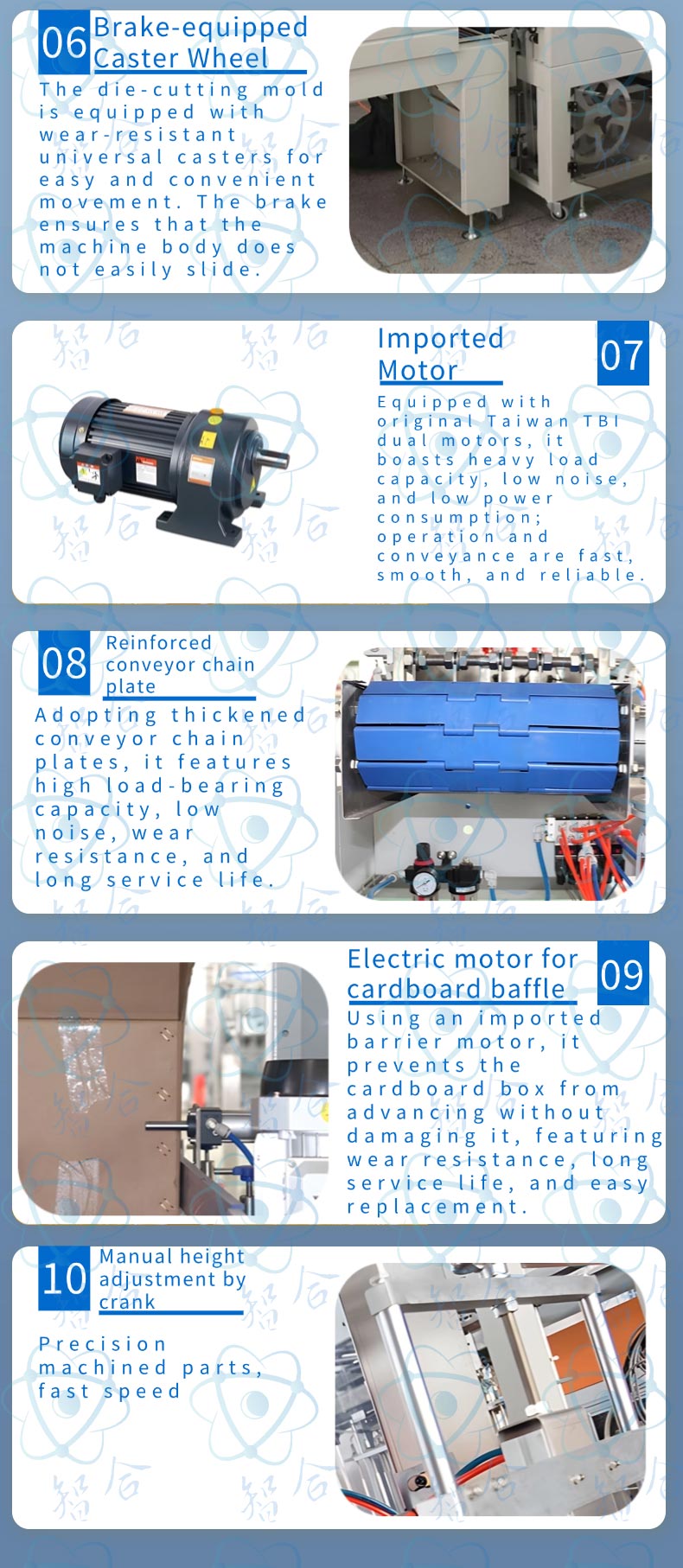

The packing motion is driven by a high-performance gearmotor, achieving smooth lifting and lowering of bottles through a unique chain mechanism.

Startup and final actions are slow and smooth, with mid-journey acceleration to improve production efficiency, while ensuring stability and accuracy during the motion process.

Production Efficiency:

The machine can automatically adjust its operating speed to synchronize with the entire production line, reducing waiting time.

With a high-efficiency packing speed of 5-15 boxes/minute, it meets various production demands.

Ease of Operation:

Fully automatic operation mode, requiring no manual intervention, reducing labor intensity.

Computer programmed control system with simple and intuitive operation, allowing easy setting and adjustment of parameters through the Weinview touchscreen.

Structural Rationality and Advanced Nature:

The mechanical structure is reasonably designed, with reliable pneumatic devices and advanced electronic control technology, perfectly combined to ensure efficient machine operation.

Compact structure with a small footprint, facilitating easy maintenance and servicing.

Safety and Reliability:

The equipment is equipped with protective covers and nets to prevent operators from entering hazardous areas.

Photoelectric safety protection devices automatically shut down the machine upon detecting unauthorized entry, ensuring personnel safety.

Hygiene Requirements:

Low noise, complying with environmental protection requirements.

Oil-free lubrication pneumatic components are used to avoid oil contamination of products.

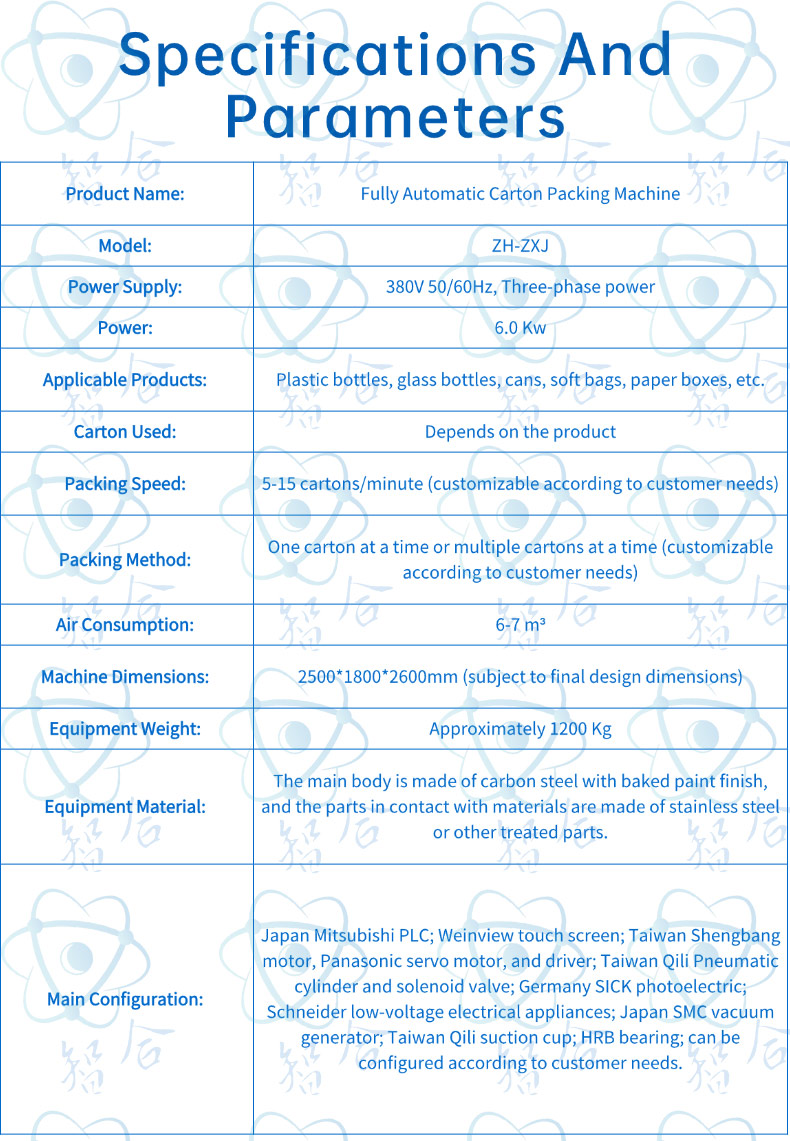

III. Main Configurations and Parameters

Model: ZH-ZXJ

Power Supply: 380V 50HZ 3P

Power: 6KW

Applicable Products: Plastic bottles, glass bottles, cans, soft bags, cartons, etc.

Carton Usage: Customized according to product specifications

Packing Speed: 5-15 boxes/minute

Packing Method: One or multiple boxes per cycle, flexibly adjustable

Air Source Usage: 6-7kg/cubic meter

Machine Dimensions: 250018002600mm (subject to final design dimensions)

Equipment Weight: Approximately 1000KG

Equipment Material: The main body is treated with carbon steel paint, with stainless steel or other corrosion-resistant materials used for parts in contact with materials.

Main Configurations:

PLC Controller: Mitsubishi (Japan)

Touchscreen: Weinview

Motors: Cheng Bang Motors (Taiwan), Panasonic servo motors and drivers

Cylinders, Solenoid Valves: AirTac (Taiwan)

Photoelectric Sensors: SICK (Germany)

Low-Voltage Electrical Appliances: Schneider

Vacuum Generators: SMC (Japan)

Suction Cups: AirTac (Taiwan)

Bearings: HRB

IV. Scope of Application and Application Scenarios

The Automatic Grab-Type Case Packer is suitable for various occasions requiring automated packing, especially in industries such as beer, beverages, food, chemicals, and pharmaceuticals. It can seamlessly connect with various production lines, improving production efficiency and reducing labor costs. Meanwhile, its flexible configuration and adjustable packing method make it adaptable to the packing needs of different specifications and types of products.

V. After-Sales Service

We provide comprehensive after-sales services, including equipment installation and commissioning, operational training, maintenance, and repairs. Additionally, we commit to providing timely technical support and solutions during equipment use to ensure continuous and stable machine operation.

In summary, the Automatic Grab-Type Case Packer is an efficient, intelligent, and reliable packing device that will bring significant improvements and benefits to your production line.