Fully Automatic Carton Opening Machine is an efficient and automated packaging equipment widely used in logistics, e-commerce, manufacturing, and other fields. Below is a detailed description of the Fully Automatic Carton Opening Machine, including its technical principles and various components:

Fully Automatic Carton Opening Machine is an efficient and automated packaging equipment widely used in logistics, e-commerce, manufacturing, and other fields. Below is a detailed description of the Fully Automatic Carton Opening Machine, including its technical principles and various components:

I. Technical Principles

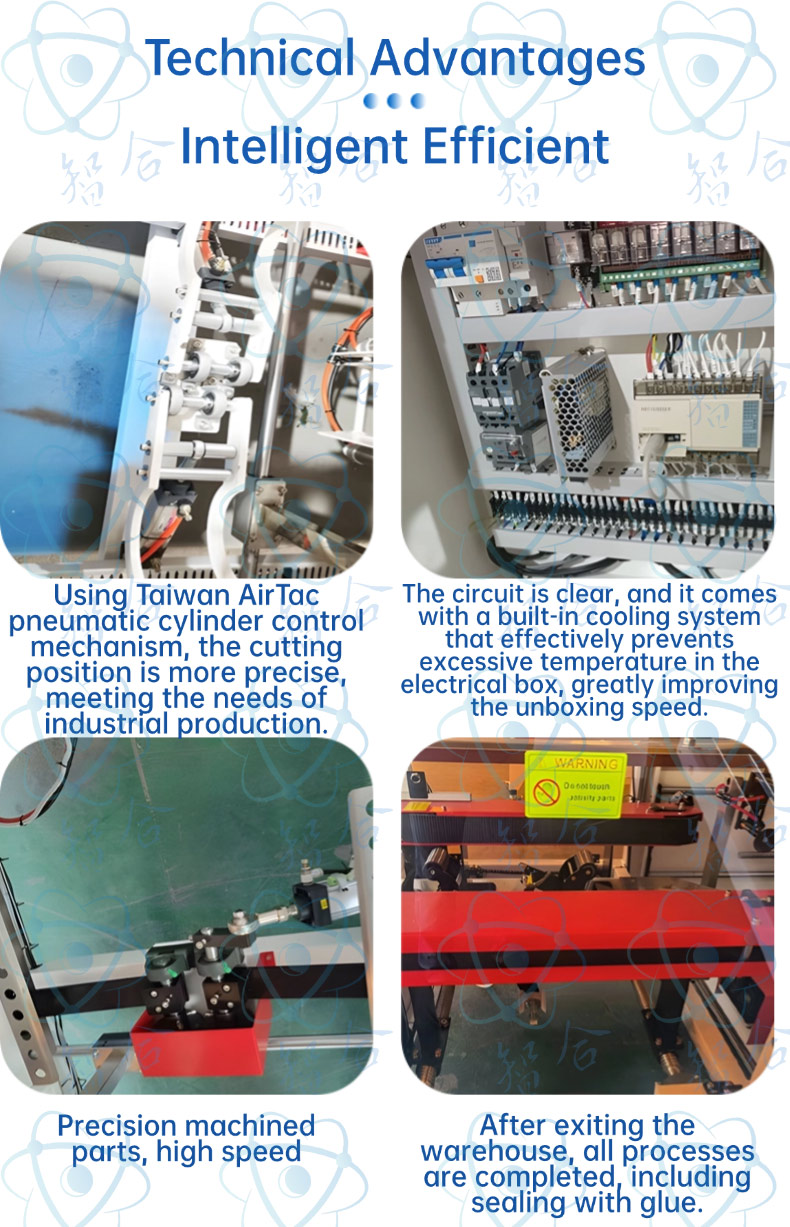

The working principle of the Fully Automatic Carton Opening Machine is mainly based on automation control technology and mechanical transmission principles. It utilizes precise sensors and control systems to achieve automatic identification, positioning, and opening of cartons. At the same time, mechanical transmission devices complete operations such as carton shaping, flap folding, and bottom sealing.

II. Components and Detailed Descriptions

Main Frame:

The main frame is the primary structure of the opening machine, composed of brackets, box plates, lead screws, guide rods, base wheels, supports, control boxes, aluminum alloy frames, and other parts. The main role of the main frame is to assemble various mechanisms into a complete opening machine system.

Feeding Device (Carton Loading Mechanism):

The feeding device is responsible for transporting flat cartons to the working area of the opening machine. It typically consists of a main frame, carton rear baffle, guide rods, sliders, lead screws, nuts, hand wheels, bearings, left and right fixed plates for cartons, etc. By adjusting the hand wheel and lead screw, the height of the loading mechanism can be adjusted to accommodate different heights of carton boards.

Pick-up Device (Vacuum Carton Suction Mechanism):

The pick-up device uses vacuum suction cups to lift cartons from the feeding device and transport them to the shaping device. The vacuum suction cups create a negative pressure to adhere to the cartons, ensuring they do not fall off during transportation.

Shaping Device:

The shaping device is responsible for forming flat cartons into a three-dimensional structure. It usually consists of a rod fixed to the main frame (shaping push box device) and a shaping template. When a carton is transported to the shaping device, the shaping template presses and molds the carton into the desired three-dimensional structure.

Flap Folding Device:

The flap folding device is responsible for folding the carton flaps. It typically consists of short-side flap folding mechanisms and long-side flap folding mechanisms for cartons. The short-side flap folding mechanism first folds the two short sides of the carton, followed by the long-side flap folding mechanism folding the two long sides, completing the entire flap folding process.

Sealing Device:

The sealing device is responsible for sealing the bottom of the carton with adhesive tape. It usually consists of sealing belts, sealing tape, and cutting blades. When a carton is transported to the sealing device, the sealing belts move the carton forward while the sealing tape is adhered to the bottom of the carton. The cutting blade is responsible for cutting off excess tape to ensure a neat sealing effect.

Conveying Device (Carton Guide Rail Mechanism):

The conveying device is responsible for transporting cartons throughout the opening machine system. It typically consists of guide rails, rollers, and transmission devices. The guide rails ensure that the cartons maintain a stable path during transportation, while the rollers reduce friction between the cartons and guide rails, improving transportation efficiency. The transmission device drives the rollers to rotate, realizing carton conveyance.

Control System:

The control system is the core part of the opening machine, responsible for controlling the operation of various devices and coordinating the entire opening process. It usually adopts a PLC (Programmable Logic Controller) and a human-machine interface for control. The PLC receives signals from sensors and issues control instructions according to preset programs, while the human-machine interface provides an interface for user interaction with the opening machine.

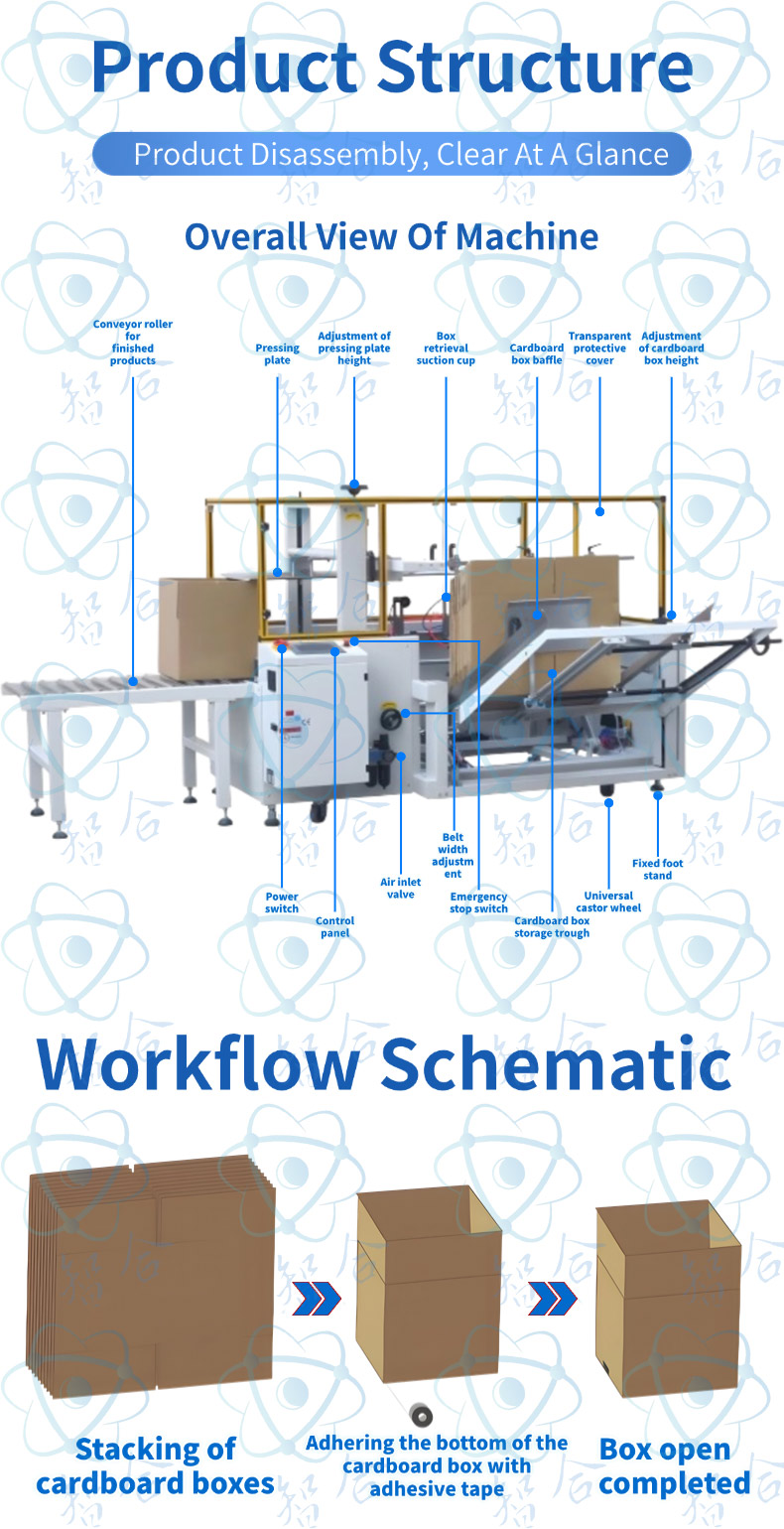

III. Workflow

- Cartons are placed on the feeding device.

- The pick-up device uses vacuum suction cups to lift cartons from the feeding device and transport them to the shaping device.

- The shaping device forms flat cartons into a three-dimensional structure.

- The flap folding device folds the carton flaps.

- The sealing device seals the bottom of the carton with adhesive tape.

- The conveying device transports the sealed carton to the next work process.

IV. Functional Characteristics

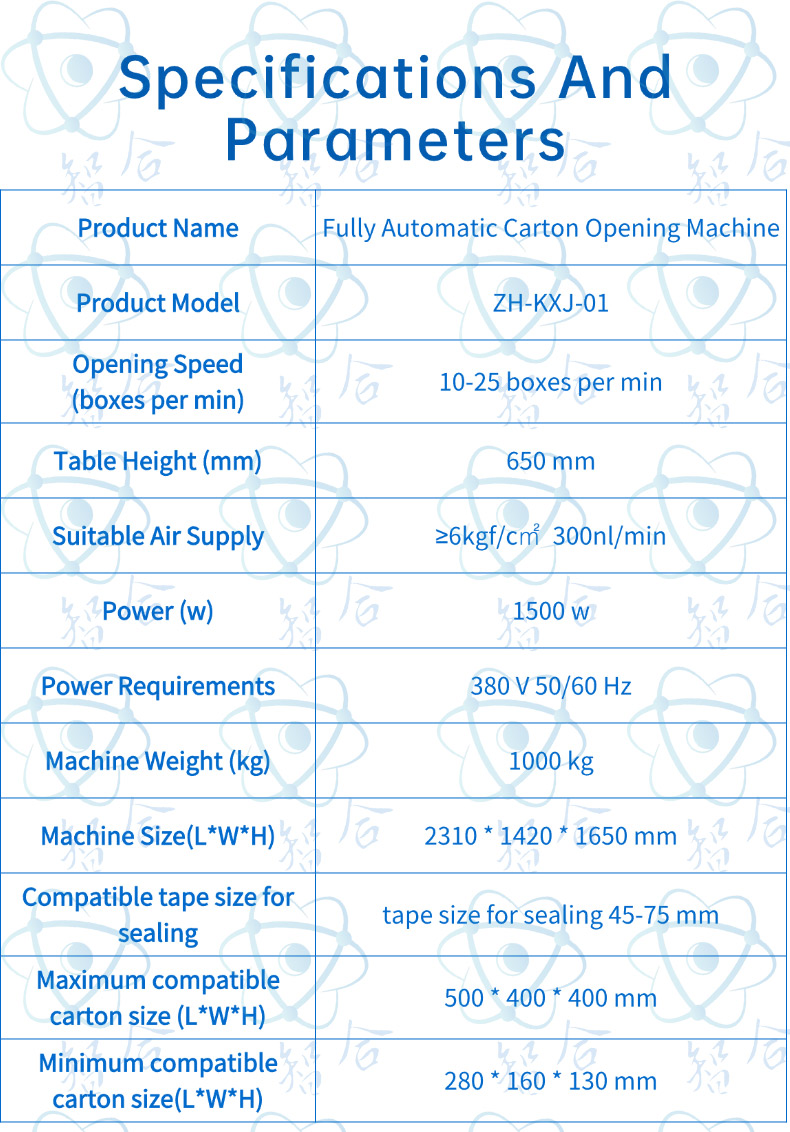

Efficiency: The Fully Automatic Carton Opening Machine can quickly and accurately complete operations such as opening, shaping, flap folding, and bottom sealing, significantly improving logistics operation efficiency.

Applicability: It is suitable for different sizes and types of cartons, meeting packaging needs across various industries.

Ease of Operation: Controlled by PLC and a human-machine interface, operation is simple and convenient.

Durability: Manufactured with high-quality materials and advanced manufacturing processes, it exhibits high durability and reliability.