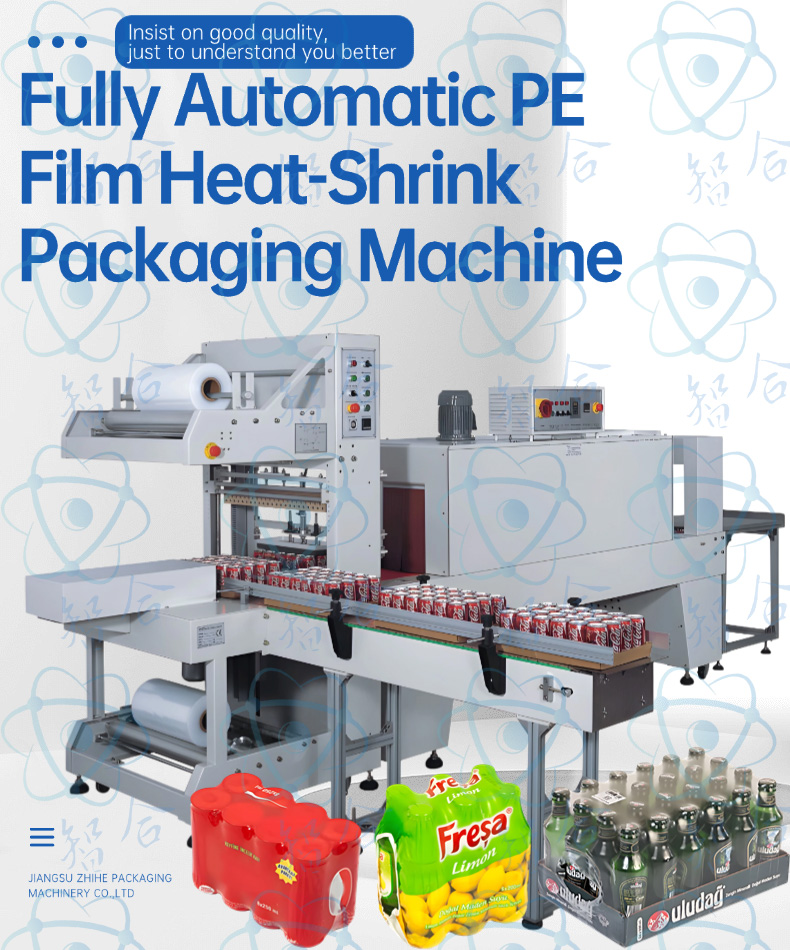

The fully automatic PE film heat-shrink packaging machine is specifically designed for packaging bottled or canned products such as mineral water, fruit juice, liquor, beer, and infusion bottles. With high specificity and stable performance, this model tightly wraps products in PE film, achieving a firm and aesthetically pleasing packaging effect. As a single-push model, it enhances production efficiency while ensuring uniformity and consistency in packaging.

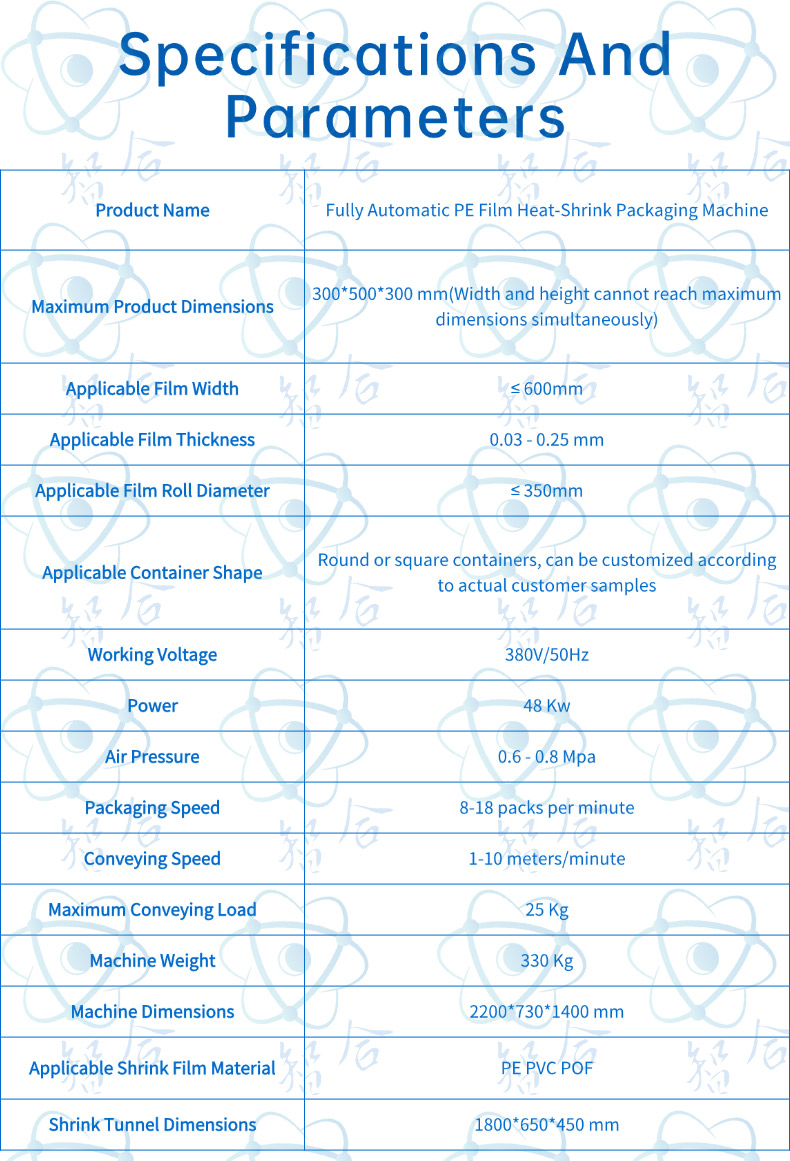

Technical Features

Unique Split Design:

- The equipment adopts a unique split design, separating the automatic sealing and cutting machine from the dual-cycle heat shrinker. This design facilitates both integrated and standalone operation, enhancing the equipment’s flexibility and practicality.

Advanced Sealing and Cutting Technology:

- The sealing and cutting section utilizes Italian hot-seal/cold-cut or hot-cut technology, ensuring stable and reliable sealing quality that fully complies with international quality standards. Both cold and hot cutting can achieve ideal sealing results.

Flexible Speed Adjustment in Heat Shrinker:

- The heat shrinker is equipped with a speed-adjustable motor supporting various speed adjustment methods such as frequency conversion, mechanical manual adjustment, and electronic voltage regulation. This design enables the equipment to adapt to the shrink requirements of different types of packaged items, improving its adaptability and flexibility.

Dual Cold and Hot Air Circulation System:

- The heat shrinker employs a dual cold and hot air circulation system, ensuring uniform heat distribution within the channel. Additionally, the outer shell quickly reaches room temperature, conserving thermal energy while ensuring consistent and stable shrinking effects.

High-Quality Conveyor Belt:

- The equipment uses a Teflon conveyor belt with German technology. This belt exhibits slow heat exchange, minimal heat carrying, and high temperature resistance, wear resistance, and tensile strength, making it a premium mainstream configuration in the packaging industry.

PLC-Centered Pneumatic Control:

- Pneumatic components are controlled with a PLC as the core, utilizing mechanical synchronous control and mechanical interlocking control to ensure machine safety. This control method enhances operational stability and reliability, reducing the failure rate.

Convenient Mold Replacement:

- By changing molds, the equipment can adapt to various packaging types, improving its versatility and flexibility. This design meets different customer needs and reduces production costs.

Working Principle

Product Input:

- Products to be packaged are placed on the conveyor belt and conveyed into the equipment.

PE Film Wrapping:

- PE film is automatically unwound and wrapped around the products, forming an initial packaging shape.

Sealing and Cutting:

- The sealing and cutting section uses hot-seal/cold-cut or hot-cut technology to seal the PE film onto the products and cut off excess film material.

Heat Shrinking:

- Sealed products enter the heat shrinker section, where the dual cold and hot air circulation system heats and cools the PE film, causing it to tightly adhere to the products, achieving a firm and aesthetically pleasing packaging effect.

Product Output:

- Shrink-wrapped products are conveyed out of the equipment by the conveyor belt, completing the entire packaging process.

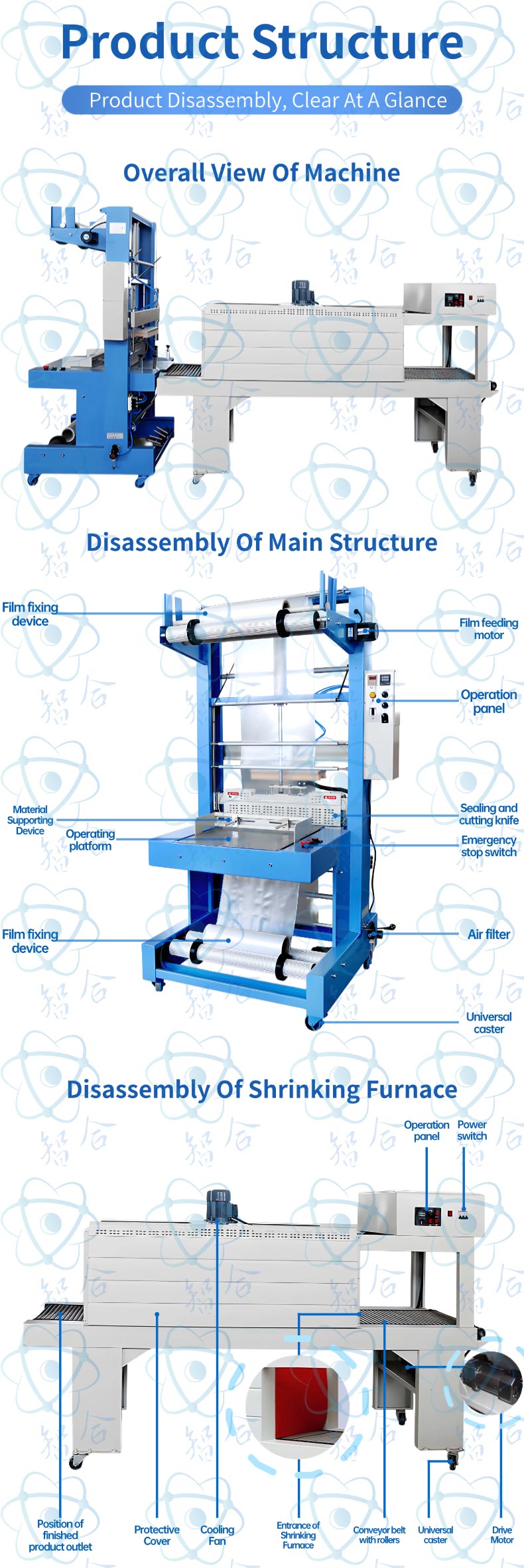

Overall Structure

The overall structure is reasonable, with a stable framework, ensuring stability and reliability during prolonged operation. Additionally, the equipment achieves energy-saving efficiency within a certain range, improving production safety and efficiency.

In summary, the fully automatic PE film heat-shrink packaging machine is a packaging equipment that combines efficiency, stability, and flexibility. It meets the needs of different customers, enhances production efficiency, and reduces production costs.