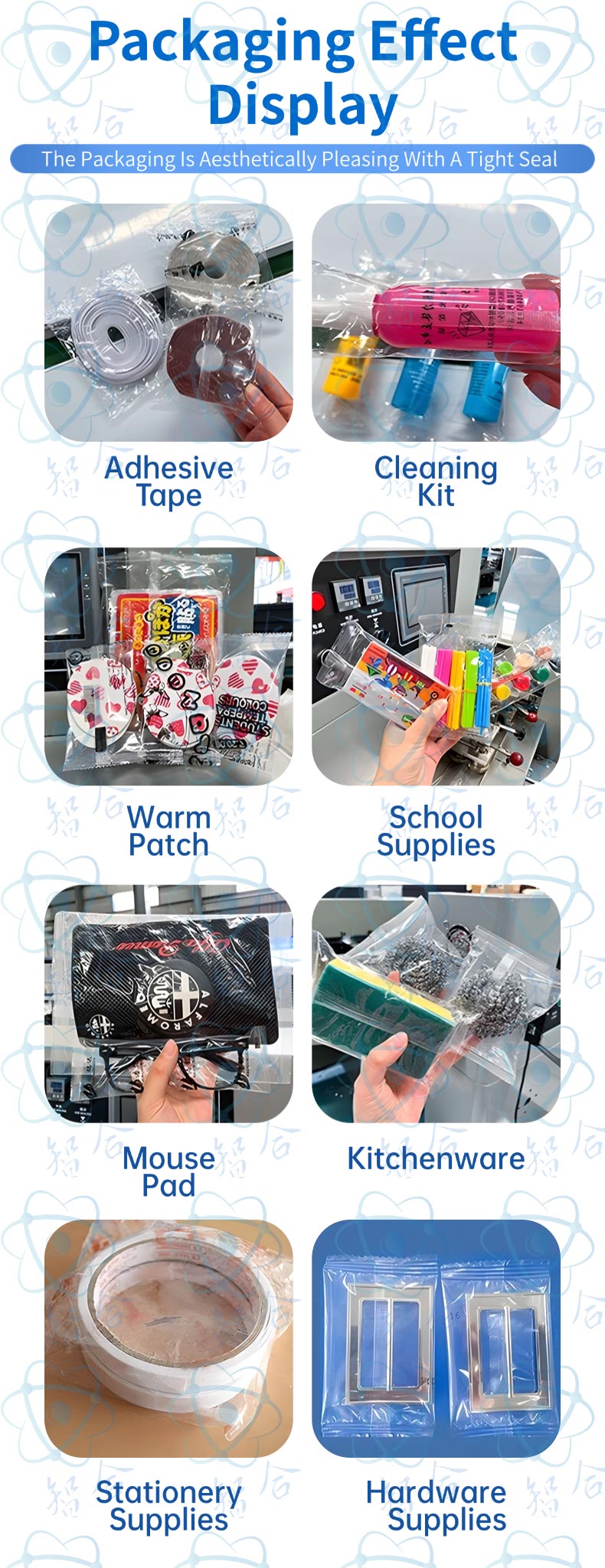

The fully automatic intelligent high-speed pillow packaging machine, as a leader in the modern packaging industry, is designed with excellence and powerful functionality, specifically designed to enhance production efficiency and product quality. It is widely used in multiple fields such as food, daily chemicals, medical, pharmaceuticals, and pesticides. Below is a detailed description of its technical characteristics and working principles:

The fully automatic intelligent high-speed pillow packaging machine, as a leader in the modern packaging industry, is designed with excellence and powerful functionality, specifically designed to enhance production efficiency and product quality. It is widely used in multiple fields such as food, daily chemicals, medical, pharmaceuticals, and pesticides. Below is a detailed description of its technical characteristics and working principles:

Technical Characteristics

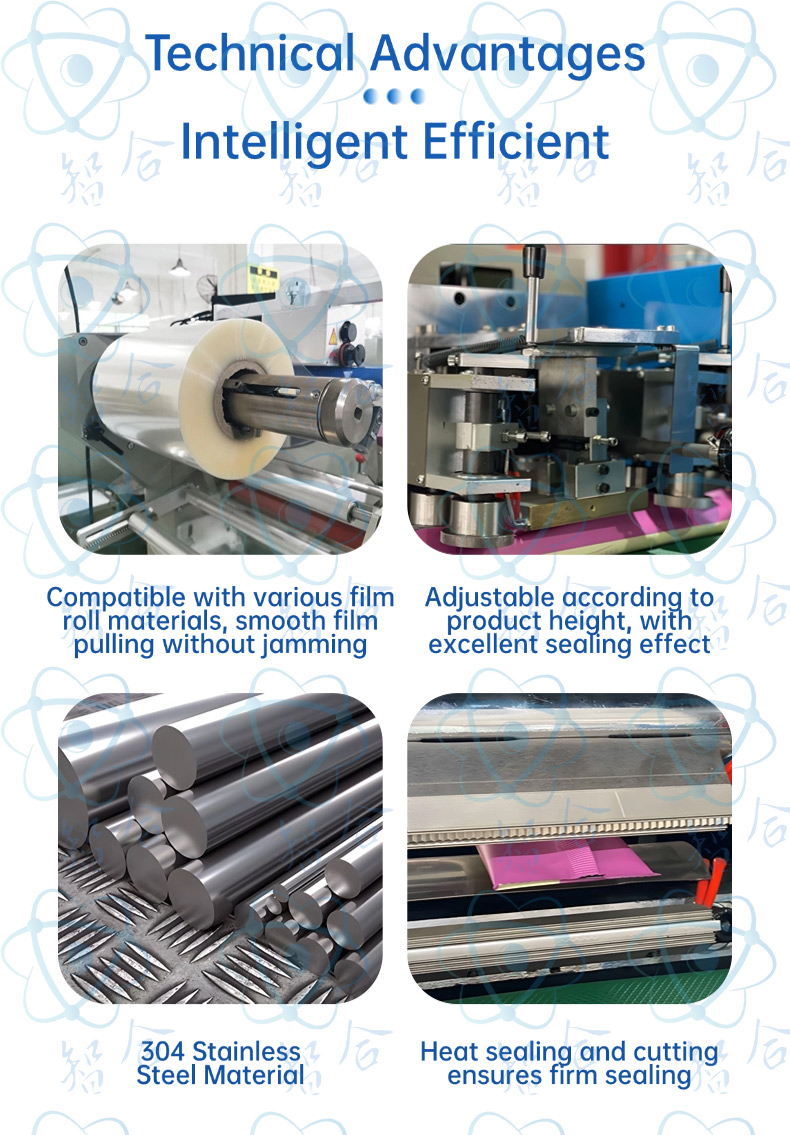

Safe and Durable Materials: The entire machine is primarily constructed with 304 stainless steel. For special materials requiring higher corrosion resistance, 316 stainless steel can be selected to ensure equipment stability and food-grade safety standards in damp or chemical environments.

Intelligent Control System: Equipped with an advanced microcomputer control system, it achieves fully automated operation and precise control. The system supports multiple programming modes, allowing flexible adjustment of packaging parameters such as packaging length, speed, temperature, etc., to ensure optimal packaging effects.

High-Precision Photoelectric Induction: Utilizing high-sensitivity photoelectric sensors, it automatically senses and accurately tracks material positions and speeds, ensuring precise alignment between the packaging film and materials, reducing waste production, and improving packaging quality.

Servo Drive Technology: Employing dual servo motors combined with precision baffle devices, it achieves precise positioning and spacing adjustment of products. The servo speed control system rapidly responds to changes in production demands, ensuring products are neatly aligned for subsequent packaging operations.

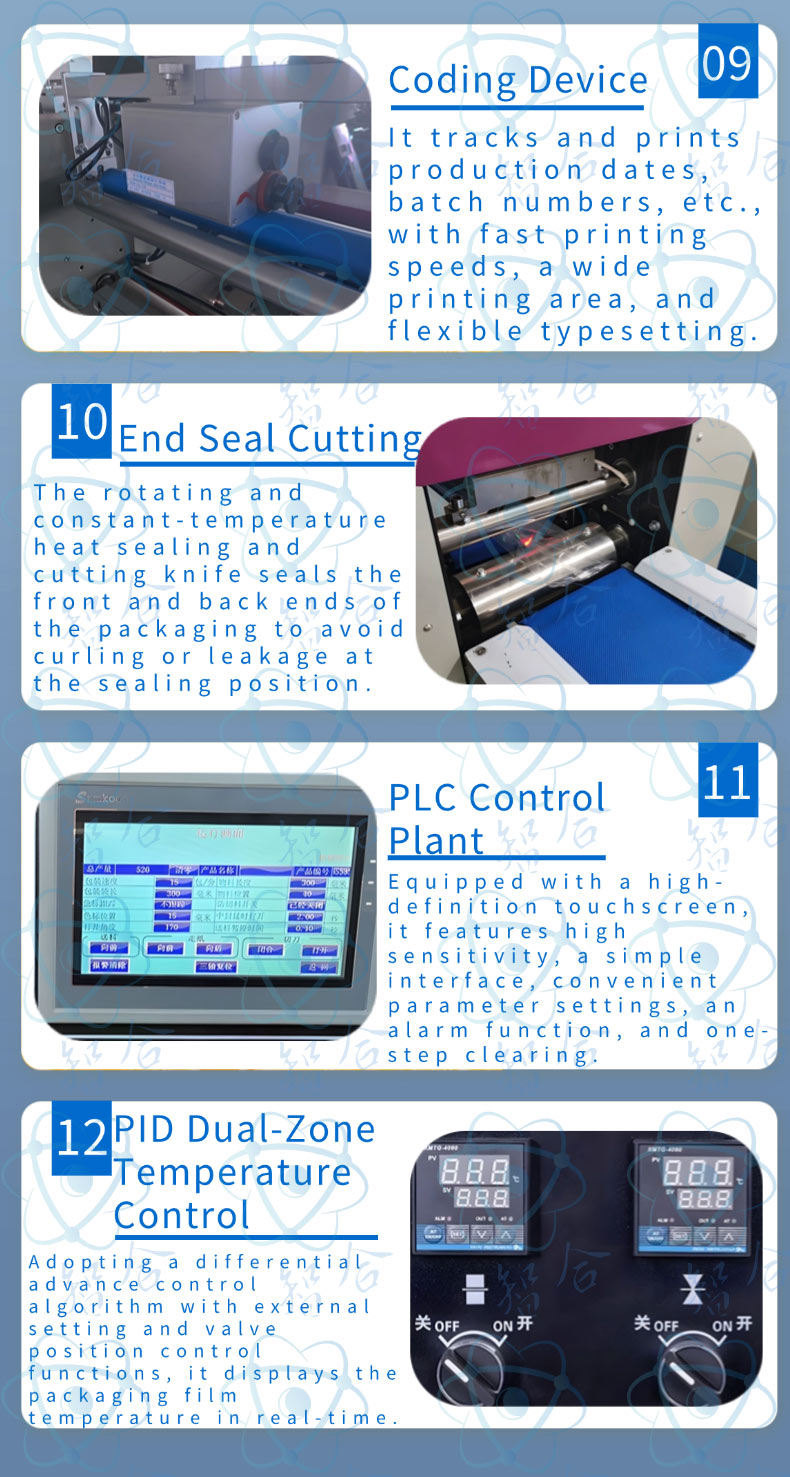

Multi-functional Expandability: Based on customer requirements, auxiliary equipment such as coding machines, labeling machines, and air rinsing machines can be configured to achieve multiple functions such as printing production dates, batch numbers, attaching product labels, and cleaning packaging surfaces, meeting the personalized packaging needs of different industries and products.

Unattended Operation and High-efficiency Production: The entire line design focuses on automation and intelligence, supporting 24/7 uninterrupted production, significantly reducing labor costs, and enhancing production efficiency. Additionally, it is equipped with remote monitoring and fault warning systems to ensure stability and safety during production.

Working Principle

The working process of the fully automatic intelligent high-speed pillow packaging machine is roughly as follows:

Loading and Positioning: Raw materials are fed through an automatic feeding system or manually placed in a designated position, detected and tracked by photoelectric sensors. The baffle device driven by the servo motor, based on preset parameters, laterally spaces the materials at an appropriate distance to form a neat arrangement.

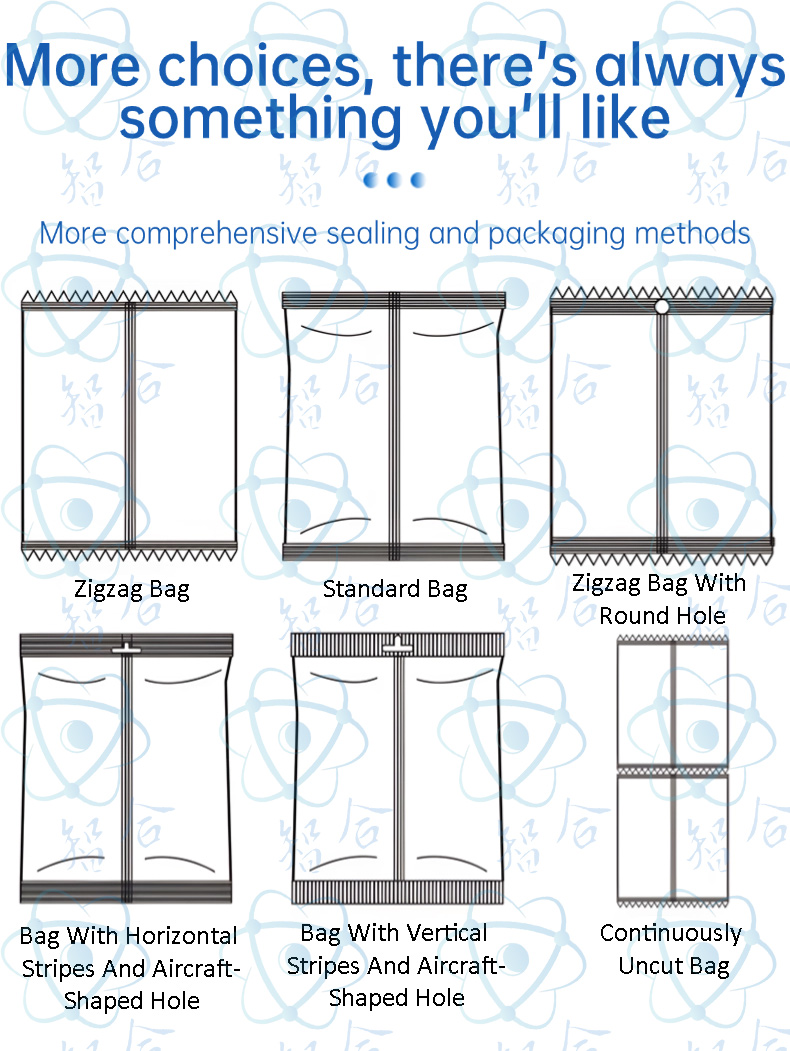

Film Supply and Forming: The packaging film is continuously supplied by the film feeding system and shaped into a bag by the former. Depending on product shape and size, the former can be flexibly adjusted to ensure the packaging bag perfectly fits the product.

Sealing and Cutting: When materials enter the packaging area, the sealing device quickly heat-seals the packaging film to form a sealed bag opening. Subsequently, the cutting knife cuts the packaging film according to the preset length to complete the packaging of a single product.

Post-processing: Packaged products are conveyed to the next process via a conveyor belt, such as coding, labeling, or collection. Meanwhile, the system continuously monitors packaging quality. If any defective products are detected, they are automatically rejected or an alarm is triggered.

In summary, the fully automatic intelligent high-speed pillow packaging machine, with its exceptional technical characteristics and efficient workflow, has become an indispensable piece of equipment in modern industrial production.