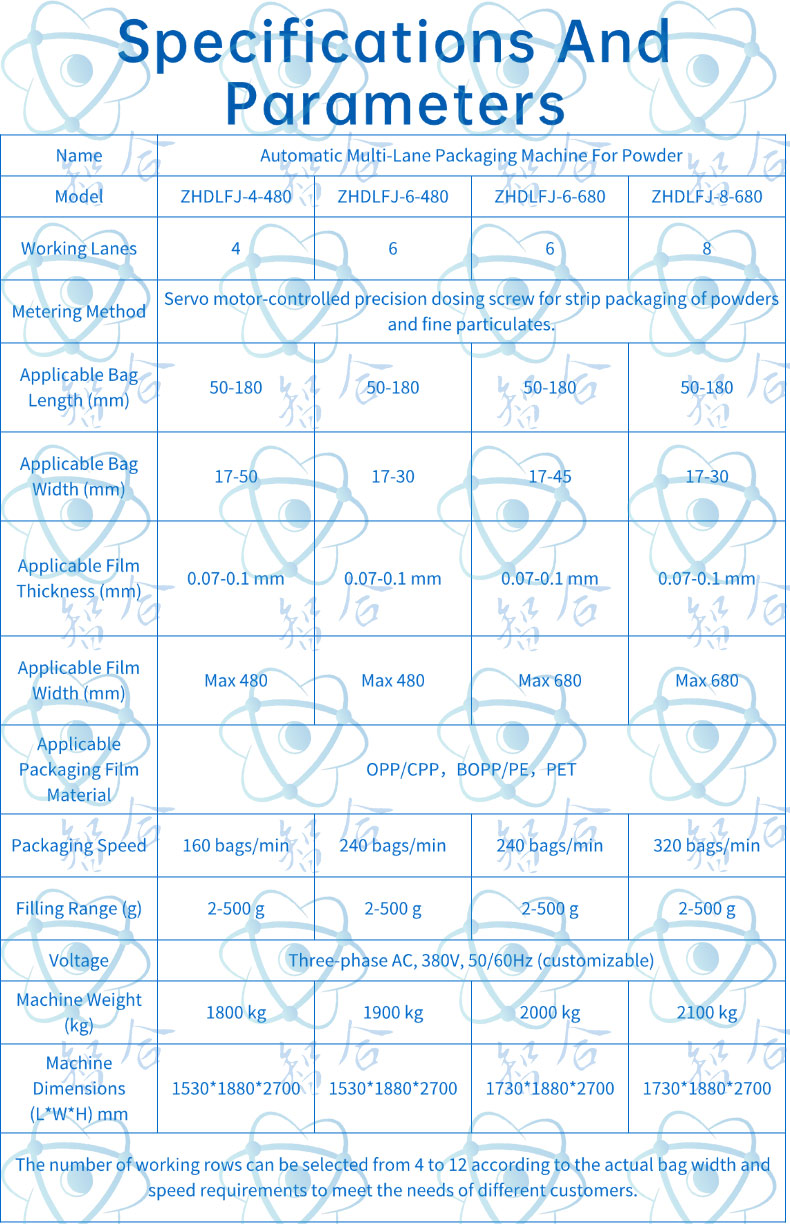

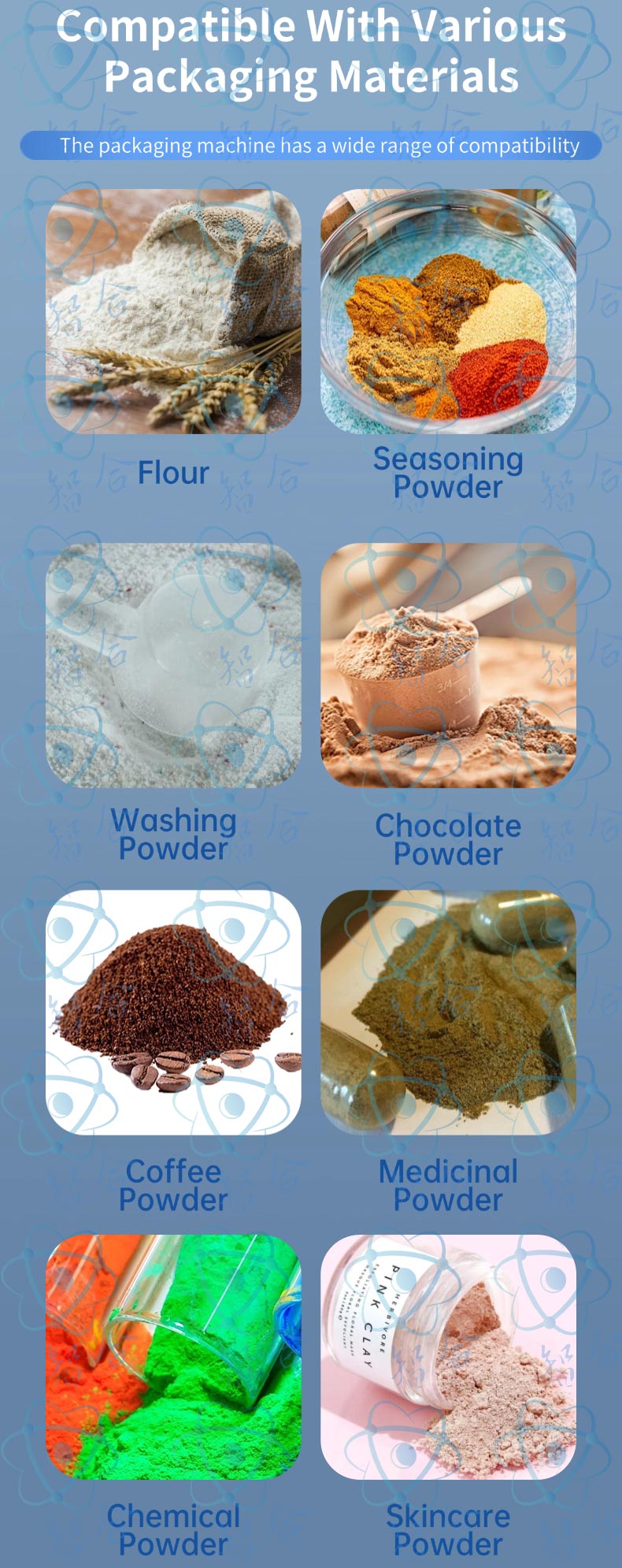

Fully Automatic Intelligent High-Speed Powder Stick Multi-Lane Packaging Machine is a highly integrated and automated equipment specifically designed for efficient and precise packaging of powder products such as coffee powder, milk powder, medicinal powder, etc. Below is a detailed description of this equipment, including its technical features, working principles, and the functions of its various components.

Fully Automatic Intelligent High-Speed Powder Stick Multi-Lane Packaging Machine is a highly integrated and automated equipment specifically designed for efficient and precise packaging of powder products such as coffee powder, milk powder, medicinal powder, etc. Below is a detailed description of this equipment, including its technical features, working principles, and the functions of its various components.

Technical Features

- High Automation: The equipment integrates a series of functions such as automatic metering, automatic filling, automatic bag-making (with printing support), sealing, package cutting, and more, requiring minimal manual intervention throughout the process, significantly enhancing production efficiency.

- Precise Metering: It adopts a servo motor-driven screw quantitative filling system to ensure the precise amount of powder in each packaging bag, improving product consistency and quality stability.

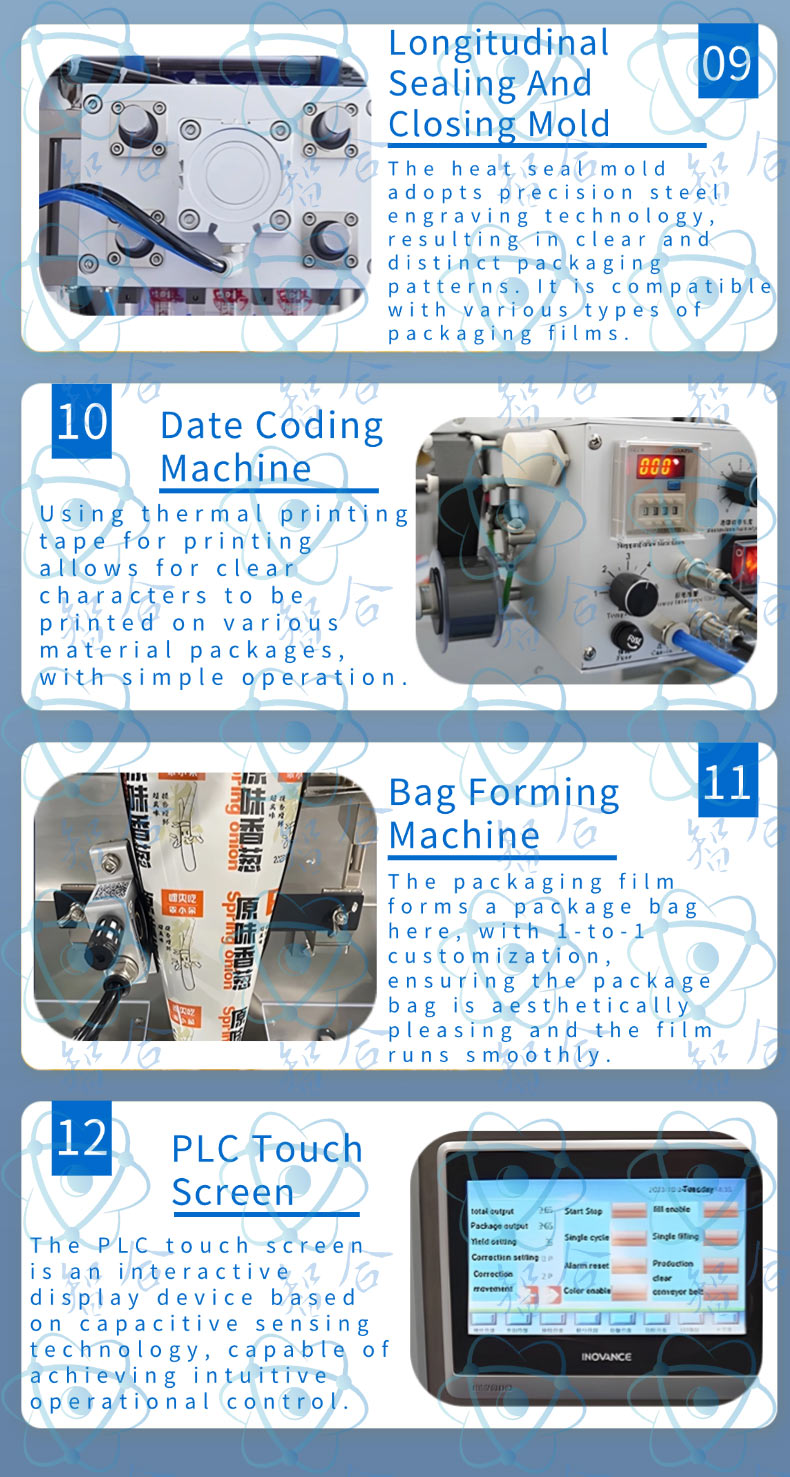

- Intelligent Control: Equipped with an advanced PLC control panel supporting touchscreen operation, users can easily set and monitor production parameters. The equipment also features fault self-alarm, self-shutdown, and self-diagnosis functions, making maintenance simple and quick.

- High-Efficiency Production: Supporting multi-lane simultaneous packaging, it greatly increases packaging speed and production efficiency, suitable for high-volume production environments.

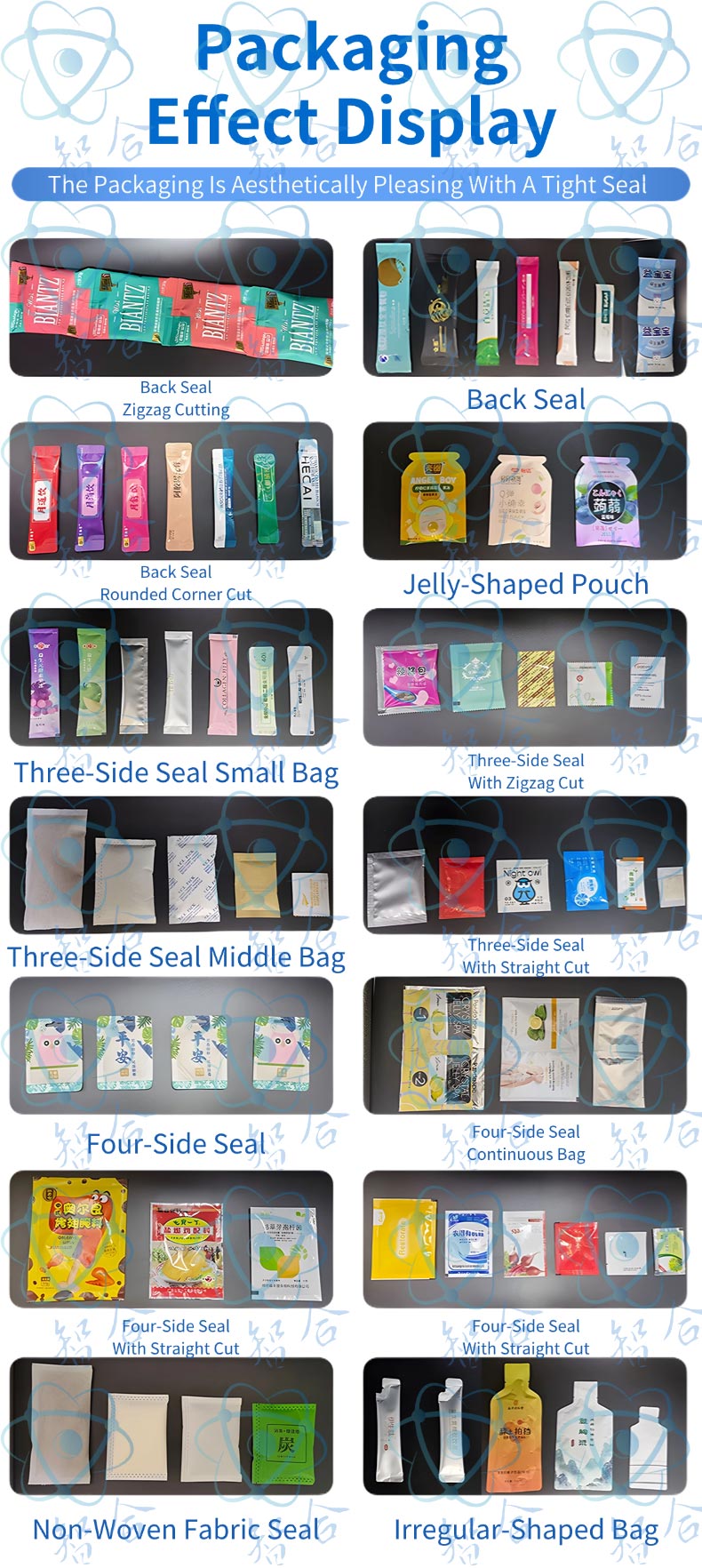

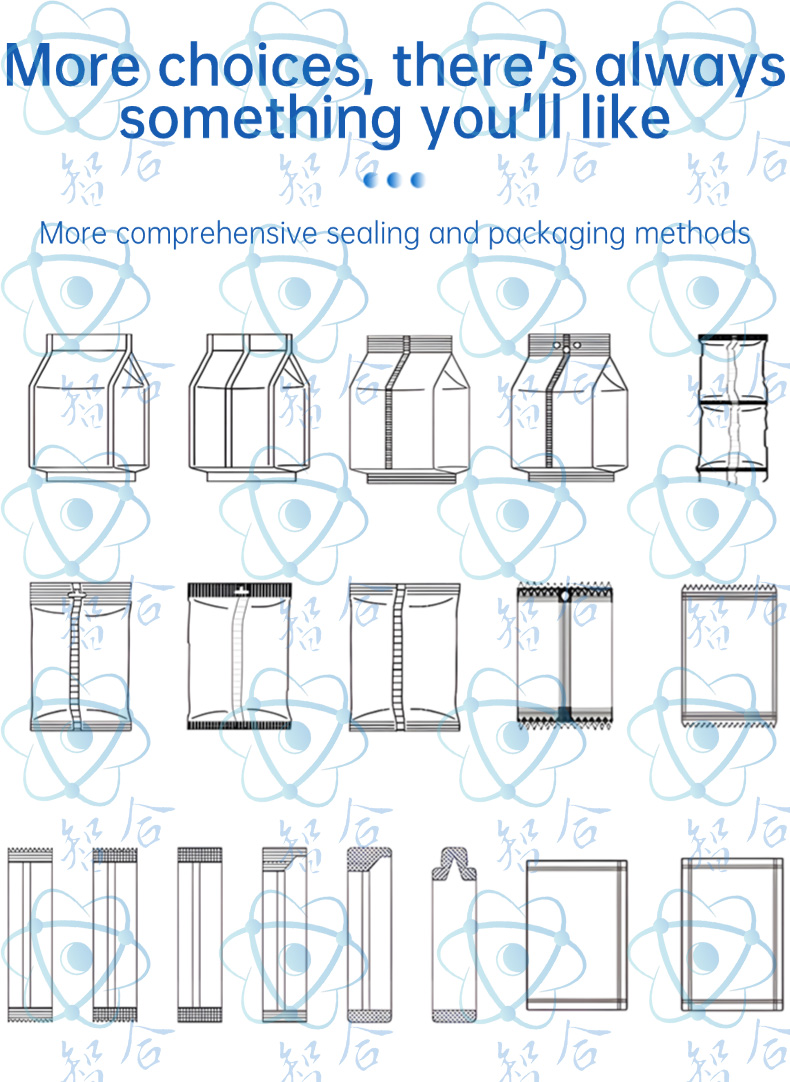

- Flexible Adaptability: It can be adjusted and customized according to different products and packaging requirements, applicable to various specifications and packaging forms of powder materials.

- Resource Conservation: Through precise packaging design and material-saving use, it reduces resource waste, aligning with sustainable production concepts.

Working Principles

- Film Supply and Bag-Making: The packaging film on the film holder, driven by the film supply motor, passes through the bag-making former, is cut, and transported to each channel to form bags of preset specifications.

- Quantitative Filling: The servo motor-driven screw precisely controls the flow of powder, filling a set amount of powder into the formed bags.

- Sealing and Cutting: After filling, the bags enter the horizontal and vertical sealing mechanisms, which seal the bags through heat sealing. Simultaneously, the cutting mechanism cuts the film during horizontal sealing, forming individual packaging bags.

- Conveying and Inspection: The finished packaging bags are conveyed to a specified location via the finished product conveyor belt. During this process, the cursor photoelectric eye automatically tracks and positions the printed cursor, ensuring the trademark pattern on the packaging material is intact. Additionally, a date coder prints the production date or batch number on the packaging bag.

- Packaging Completion: After the above steps, the packaged powder stick multi-lane finished products are finally output, completing the entire packaging process.

Components and Functions

- Film Holder: Used to place unprocessed packaging roll film, providing raw materials for the film supply system.

• Film Supply Motor: Drives the packaging film forward to the bag-making former.

• Finished Product Conveyor Belt: Conveys the packaged finished products to a specified location for subsequent processing or boxing.

• Protective Cover: Protects the internal mechanical parts and electrical components of the equipment, ensuring production safety.

• Horizontal and Vertical Sealing Dies: Seal the bags through heat sealing to ensure sealing tightness.

• Cursor Photoelectric Eye: Automatically tracks and positions the printed cursor, ensuring the trademark pattern on the packaging material is intact.

• Servo Motor-Driven Screw Quantitative Filling: Precisely controls the powder filling amount, improving packaging accuracy.

• Bag Pulling Wheel: Assists in the smooth conveyance of bags during filling and sealing.

• Date Coder: Prints the production date or batch number on the packaging bag for traceability.

• Bag-Making Former: Cuts the packaging film and transports it to each channel to form bags of preset specifications.

• PLC Control Panel: The core control system of the equipment, supporting user settings and monitoring of production parameters, with fault self-diagnosis functions.

In summary, the Fully Automatic Intelligent High-Speed Powder Stick Multi-Lane Packaging Machine, with its efficient, precise, and automated characteristics, has been widely applied in the pharmaceutical, food, and chemical industries, providing strong support for enhancing production efficiency and product quality.