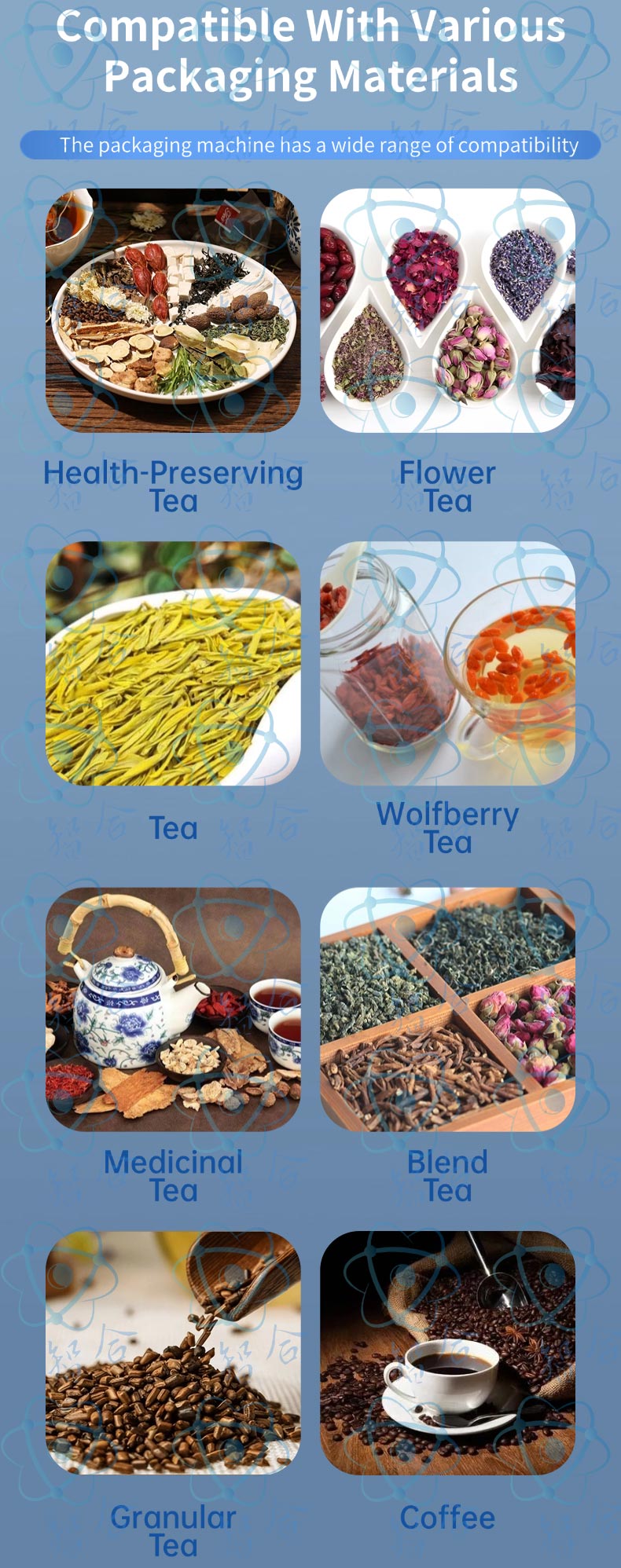

Fully Automatic Vertical Packaging Machine for Internal and External Tea Bags is an efficient, precise, and multi-functional equipment specifically designed for the one-time packaging of internal and external bags for small granular materials such as tea leaves, herbal teas, and health teas. Below is a detailed description of the technical characteristics, working principle, and components of this product:

Fully Automatic Vertical Packaging Machine for Internal and External Tea Bags is an efficient, precise, and multi-functional equipment specifically designed for the one-time packaging of internal and external bags for small granular materials such as tea leaves, herbal teas, and health teas. Below is a detailed description of the technical characteristics, working principle, and components of this product:

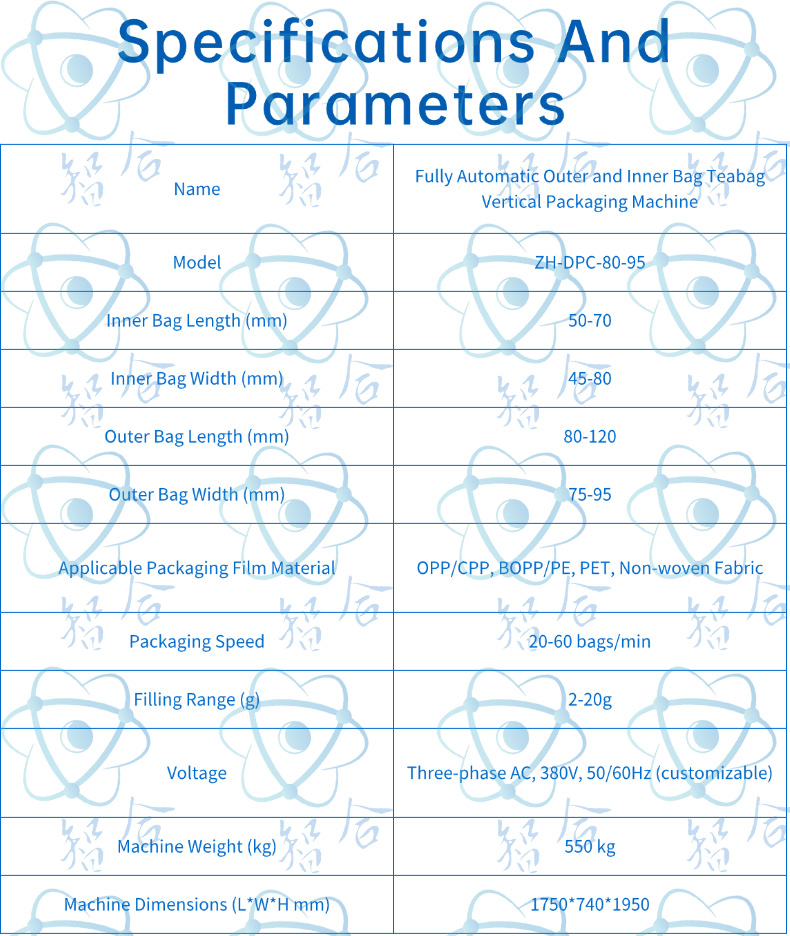

Technical Characteristics

High Automation: This packaging machine integrates multiple functions such as automatic bag making, metering, filling, sealing, cutting, counting, and date printing, significantly improving production efficiency and packaging quality.

Precise Control: Equipped with a PLC touchscreen control system, the human-machine interface is friendly and easy to operate. The color control interface ensures precise metering and consistent product content per bag.

Material Safety: All parts in contact with materials are made of SUS304 stainless steel, complying with food processing machinery hygiene standards, ensuring product hygiene and reliability.

Flexible Adjustment: Equipped with a variable frequency speed control device, the packaging speed can be adjusted within a certain range according to production needs, adapting to different production line scales.

Intelligent Detection: Built-in detection devices such as optical sensors ensure accurate bag positioning with no deviation. Additionally, the filling and sealing devices automatically stop working in cases of no packaging material or unopened packaging bags, avoiding waste.

Multi-functional Accessories: Equipped with a date coder for automatic printing of production dates or batch numbers; the external bag heat-sealing and cutting blade ensures a flat and secure seal.

Working Principle

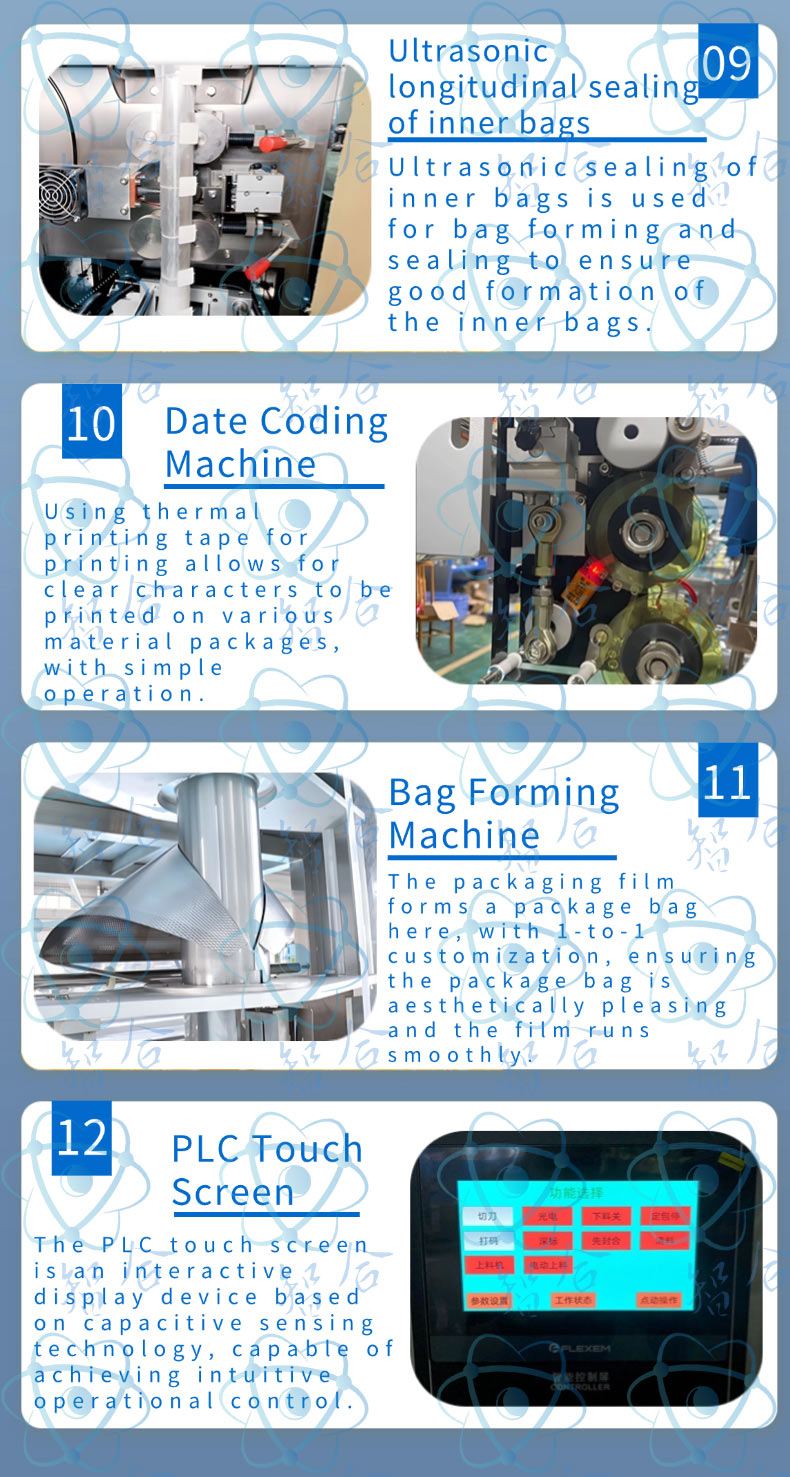

Film Supply and Bag Making: The film supply motor drives the film from the roll, passing through tensioning devices and formers to create a predetermined bag tube size. The internal and external bag-making processes are completed by their respective bag-making formers.

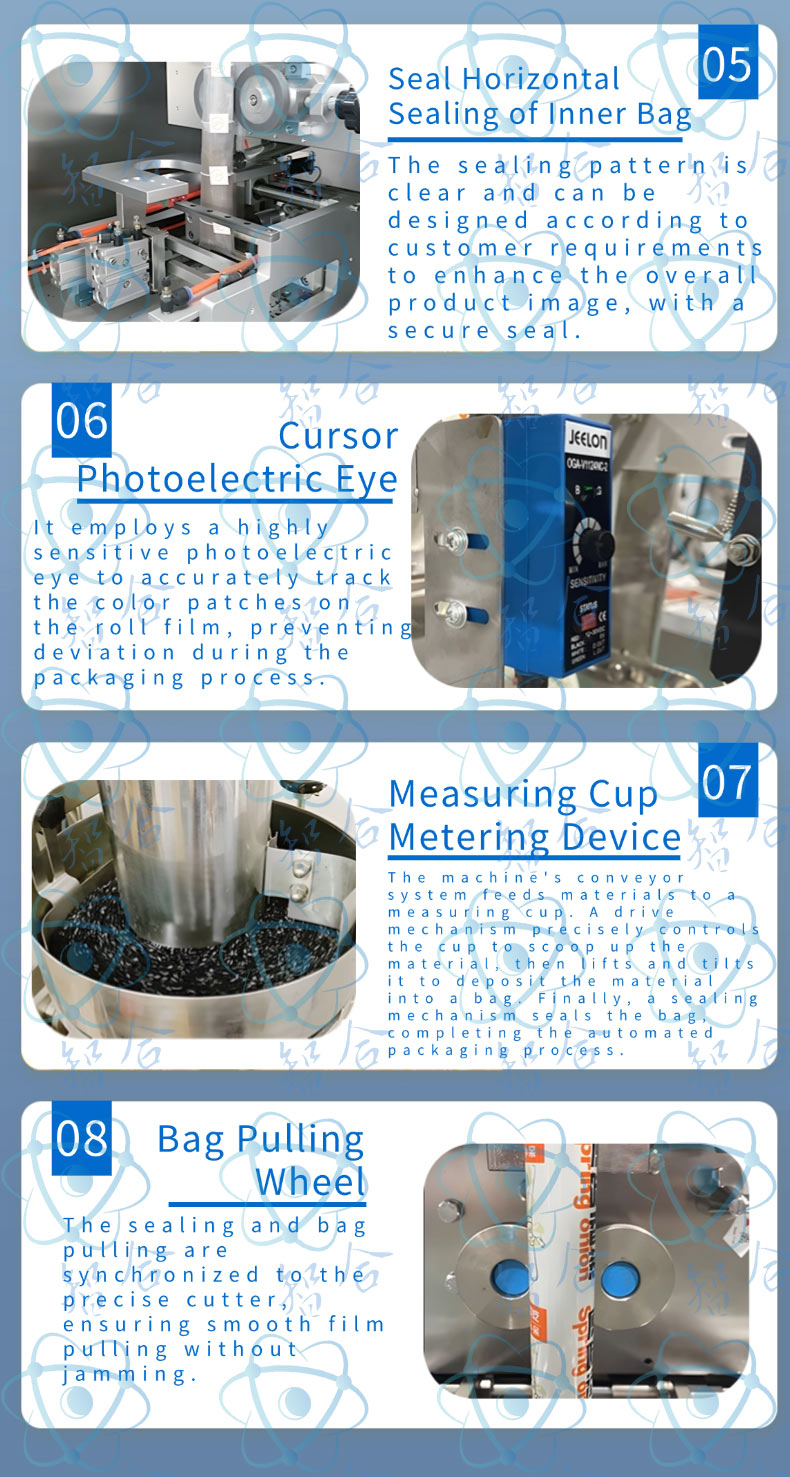

Metering and Filling: A measuring cup precisely measures the tea or other materials, which are then filled into the internal bag through a filling tube. The internal bag is sealed by ultrasonic longitudinal sealing and internal bag transverse sealing mechanisms, ensuring tightness.

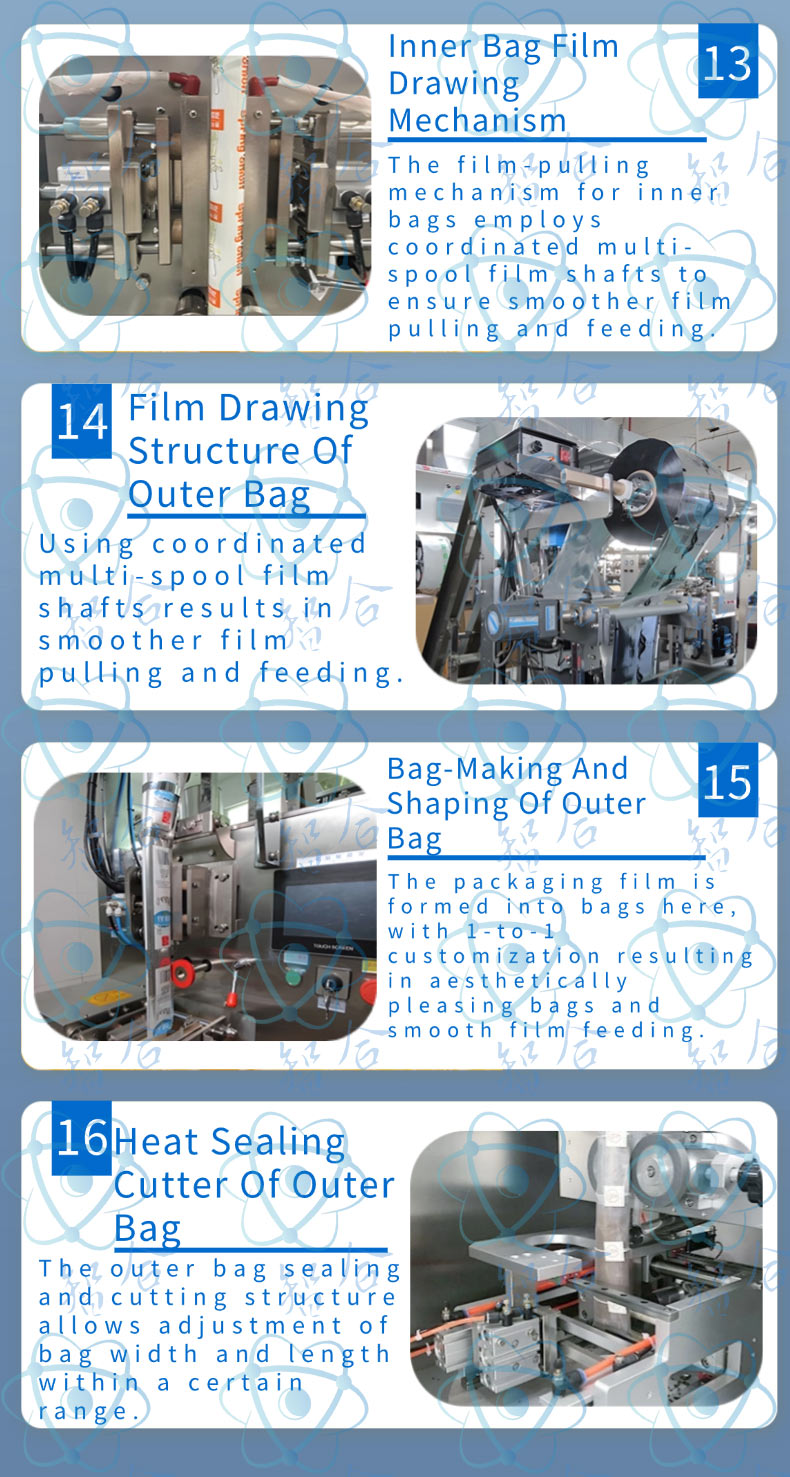

Internal and External Bag Combination: The sealed internal bag is fed into the external bag through bag-pulling wheels and film-pulling mechanisms. The external bag also undergoes bag-making forming and sealing with a heat-sealing and cutting blade, completing the simultaneous packaging of both bags.

Finished Product Output and Detection: Packaged products are conveyed out by a finished product conveyor belt, while detection devices such as optical sensors monitor packaging quality to ensure no defective products are released.

Detailed Components

50-liter Large Capacity Hopper: Provides sufficient material storage space, reducing frequent refilling and improving production efficiency.

Film Supply Motor: Drives the film roll to rotate, providing a stable film supply for the bag-making process.

Finished Product Conveyor Belt: Smoothly conveys packaged products to the next process or packaging box.

Protective Cover: Protects the internal mechanical structure of the equipment from dust and foreign objects, ensuring operational safety.

Internal Bag Transverse Sealing and Ultrasonic Longitudinal Sealing: Ensure a strong and flat internal bag seal, preventing material leakage.

Optical Sensor: Precisely detects the position of the packaging bag, ensuring accurate sealing placement.

Measuring Cup Metering Device: Precisely measures materials to ensure consistent product content per bag.

Bag-Pulling Wheels, Internal Bag Film-Pulling Mechanism, External Bag Film-Pulling Structure: Work together to accurately feed internal and external bags into the bag-making formers.

External Bag-Making Former and Heat-Sealing and Cutting Blade: Complete the bag-making and sealing processes for the external bag, ensuring complete internal and external packaging.

PLC Touchscreen: Acts as the control center of the entire machine, enabling human-machine interaction and real-time monitoring and adjustment of equipment operation status.

In summary, the Fully Automatic Vertical Packaging Machine for Internal and External Tea Bags, with its technical characteristics of high automation, precise control, material safety, and flexible adjustment, as well as its efficient and stable working principle, makes it an ideal choice for packaging small granular materials such as tea.