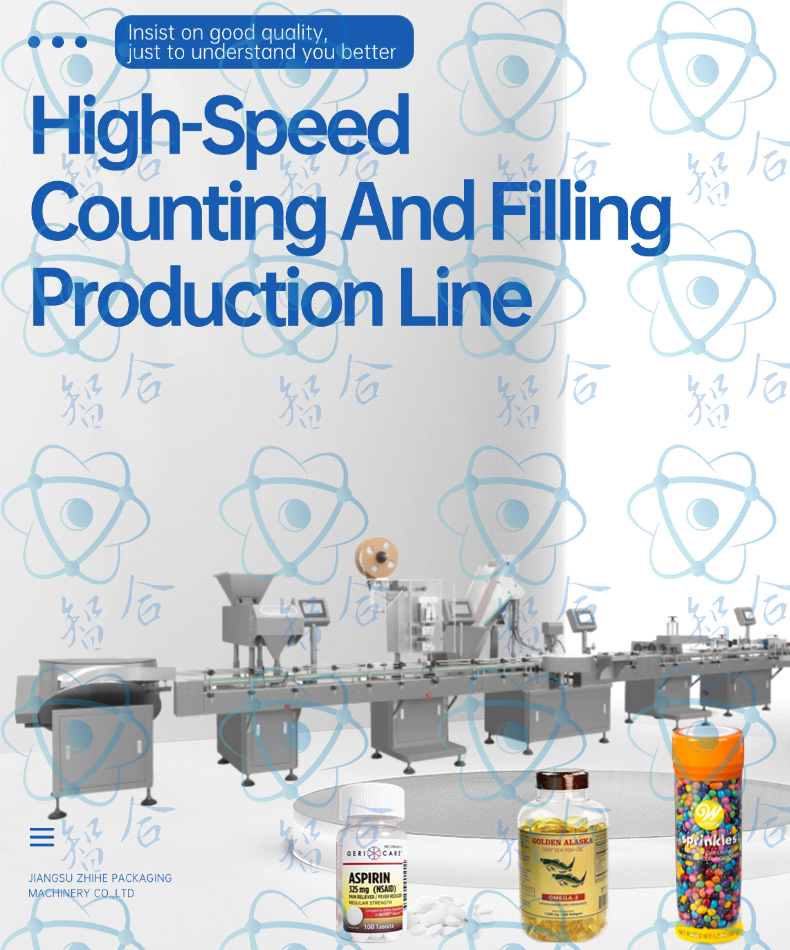

The fully automatic high-speed counting and filling production line is a modernized production line integrating precision machinery, intelligent control, and efficient production. Widely used in pharmaceuticals, food, daily chemicals, agriculture, and other industries, it realizes full automation from raw material preparation to product packaging through a highly automated equipment combination, significantly improving production efficiency and product quality. Below is a detailed description of the fully automatic high-speed counting and filling production line:

The fully automatic high-speed counting and filling production line is a modernized production line integrating precision machinery, intelligent control, and efficient production. Widely used in pharmaceuticals, food, daily chemicals, agriculture, and other industries, it realizes full automation from raw material preparation to product packaging through a highly automated equipment combination, significantly improving production efficiency and product quality. Below is a detailed description of the fully automatic high-speed counting and filling production line:

I. System Composition

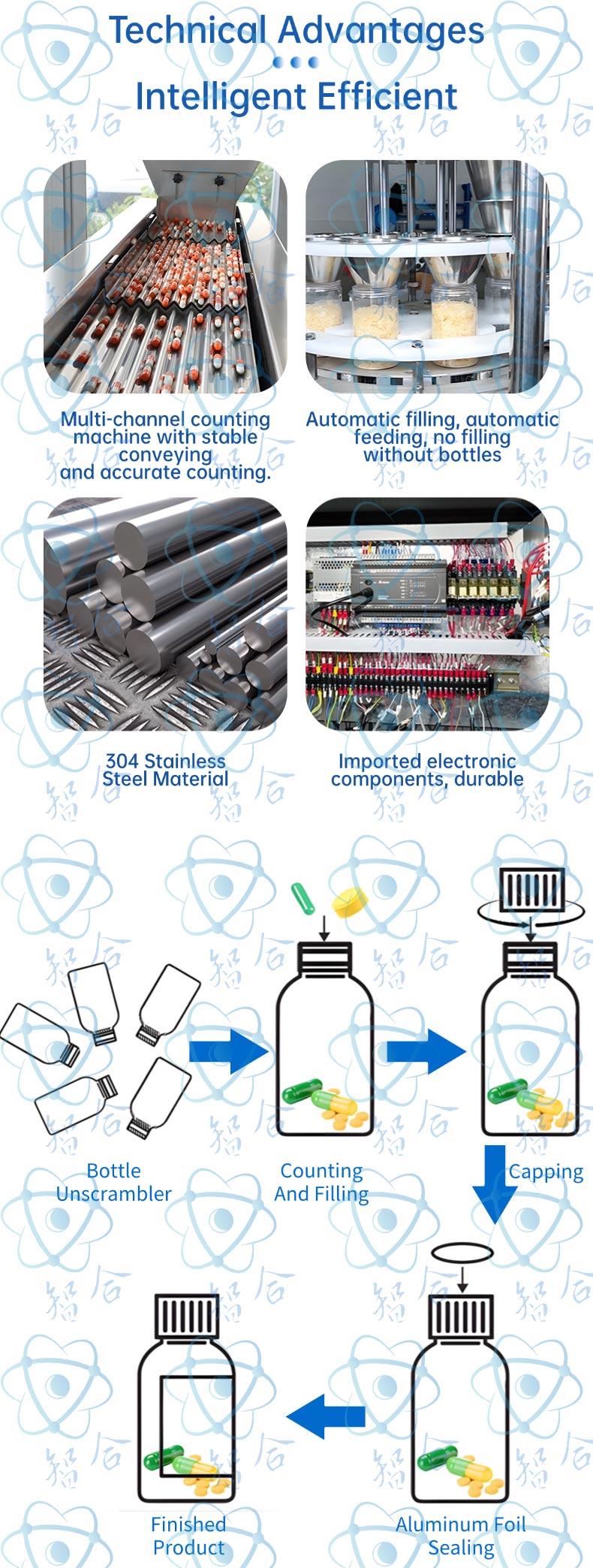

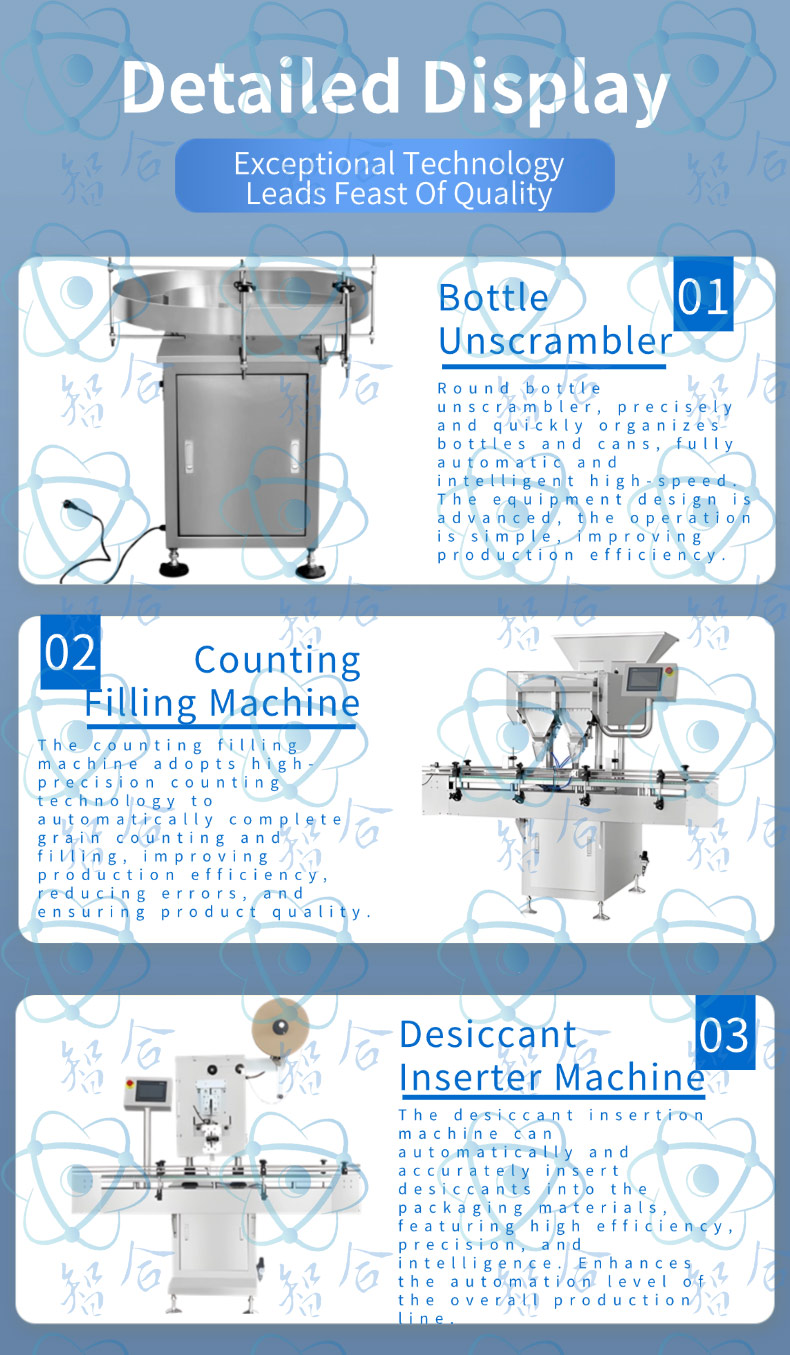

- Bottle Sorting System

- Function: Transfers packaging containers (such as bottles, jars, etc.) from their initial positions to various workstations, utilizing cylinders, chains, guide rails, belts, and other transmission devices.

- Features:

- Utilizes imported motor-driven conveyor belts for stable and efficient operation.

- Equipped with adjustable speed control to meet diverse production needs.

- Incorporates sensors and automatic deviation correction devices to ensure stability and accuracy during container transfer.

- Counting and Filling System

- Function: Accurately and rapidly counts and fills granular materials (e.g., tablets, candies, seeds) into packaging containers.

- Technical Features:

- High-precision counting: Adopts advanced counting technology and sensors to ensure accuracy and consistency in each counting operation.

- Versatile filling methods: Supports gravity filling, vibration filling, and other methods to accommodate different material properties and packaging containers.

- High filling speed: Can reach hundreds to thousands of bottles per minute, meeting high-speed production requirements.

- Intelligent adjustment: Automatically adjusts filling volume and speed based on production needs, enhancing production flexibility and efficiency.

- Desiccant Inserter

- Function: Automatically inserts desiccants into packaging containers after filling to prevent moisture.

- Features:

- Precisely controls desiccant usage, ensuring effective drying.

- Operates at high speeds with seamless integration into the filling system.

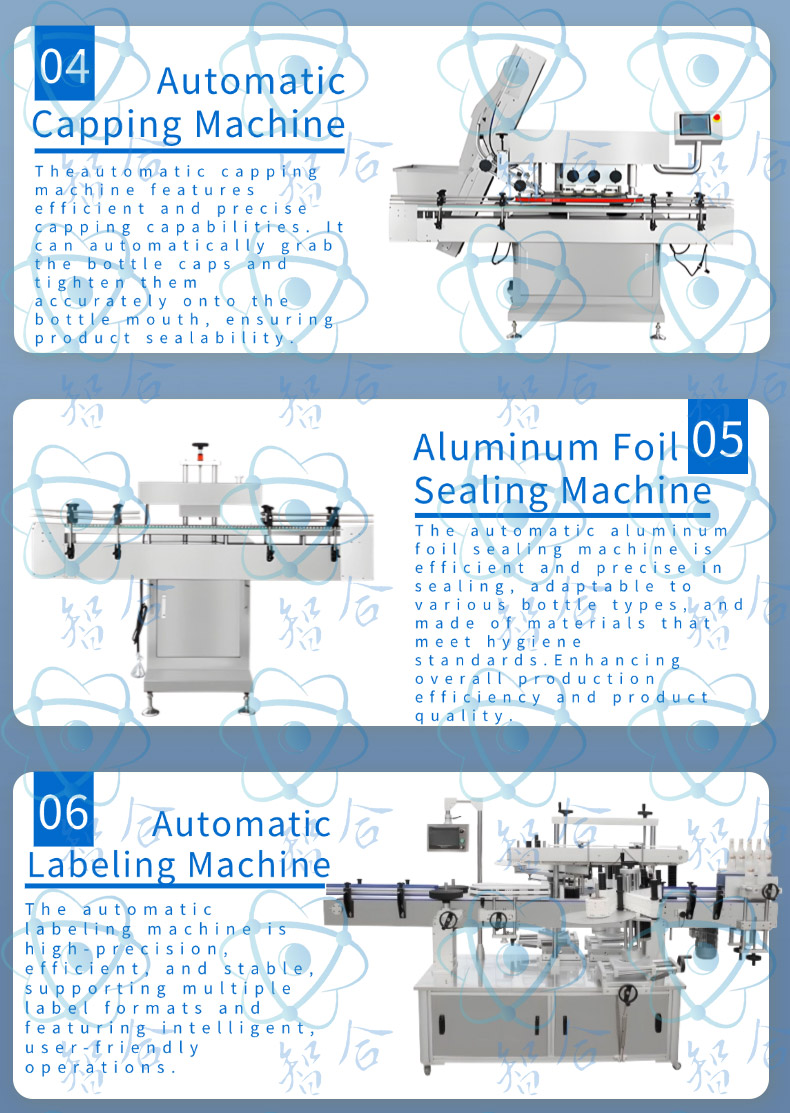

- Automatic Capping Machine

- Function: Automatically caps filled packaging containers to ensure product sealability.

- Features:

- High-speed capping to meet production demands.

- Adjustable capping torque for optimal tightness and product quality.

- Equipped with detection devices to reject loosely capped or damaged lids.

- Automatic Aluminum Foil Sealer

- Function: Applies aluminum foil seals to capped packaging containers, further enhancing product sealability and shelf life.

- Features:

- Efficient sealing to ensure seal quality.

- Adjustable sealing temperature and time for compatibility with different materials and container sizes.

- Integrated fault detection and alarm system for production safety.

- Automatic Labeling Machine

- Function: Automatically applies labels to packaging containers, enhancing product aesthetics and information identification.

- Features:

- High-speed labeling to keep pace with production demands.

- Accurate label placement with wrinkle-free results.

- Supports multiple label formats and printing methods.

- Intelligent Control System

- Function: Monitors equipment operating status, operating parameters, and output, automatically adjusting conditions and parameters to ensure stable and efficient production.

- Features:

- Uses PLC and touchscreen control for easy and intuitive operation.

- Incorporates fault diagnosis and early warning functions for proactive problem-solving.

- Connects to upper computers or MES systems for real-time monitoring and tracing of production data.

II. Advantages and Applications

Advantages

- Increases Production Efficiency: Automates production processes, significantly boosting speeds and reducing manual intervention and wait times.

- Enhances Product Quality: Ensures product consistency and high quality through precise counting and filling techniques.

- Lowers Production Costs: Reduces labor costs and material waste, improving efficiency and resource utilization.

- Enhances Production Flexibility: Quickly adjusts equipment parameters and line configurations based on production needs.

Applications

- Pharmaceutical Industry: Precise counting and filling of granules, tablets, capsules, and other medications.

- Food Industry: Filling of granular materials such as candies, nuts, and condiments.

- Daily Chemicals Industry: Filling of granular products like cosmetics and skincare items (continued from previous text).