The fully automated intelligent high-speed particle weighing and filling production line is a modernized production line that integrates precision mechanical systems, intelligent control systems, and efficient production processes. It is widely used in various industries such as pharmaceuticals, cosmetics, food, daily chemicals, and agriculture. The following is a detailed description of this production line:

The fully automated intelligent high-speed particle weighing and filling production line is a modernized production line that integrates precision mechanical systems, intelligent control systems, and efficient production processes. It is widely used in various industries such as pharmaceuticals, cosmetics, food, daily chemicals, and agriculture. The following is a detailed description of this production line:

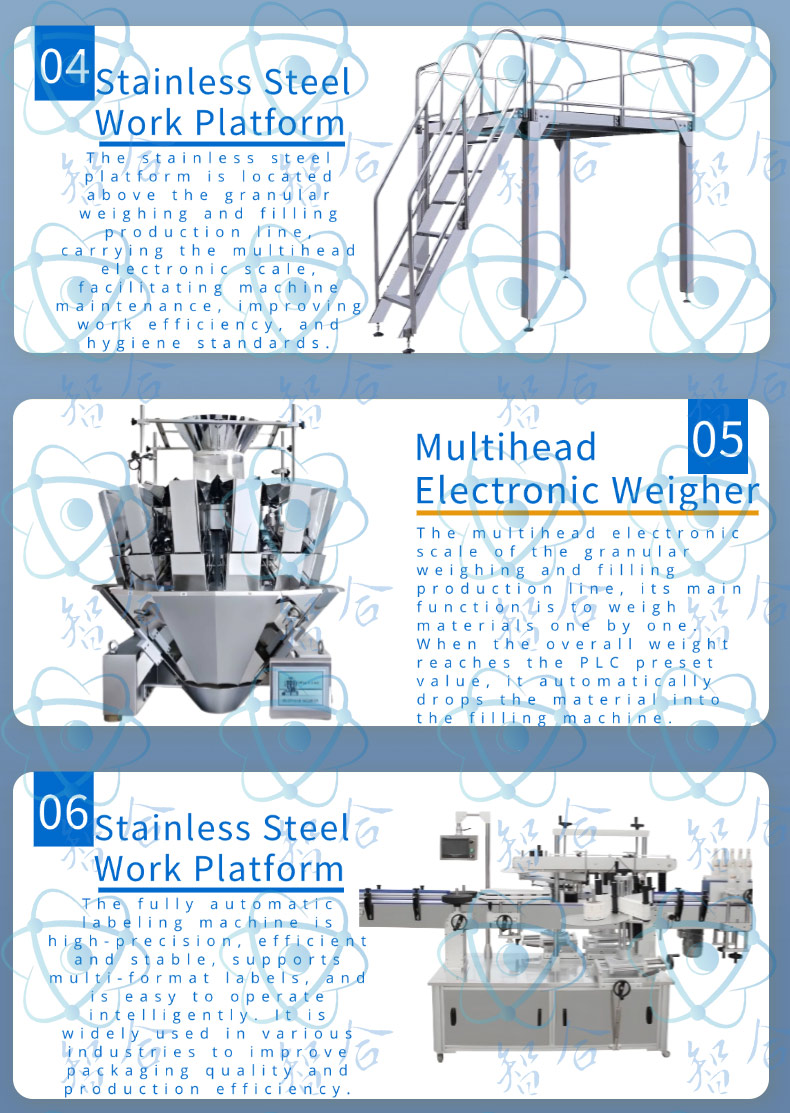

I. System Composition

- Conveyor System

- Function: Transports packaging containers (such as bottles, jars, etc.) from their initial positions to various workstations, including cylinders, chains, guide rails, belts, and other transmission devices.

- Features: Uses imported motor-driven conveyor belts to ensure stable and efficient operation with adjustable speed control to meet different production needs.

- Filling System

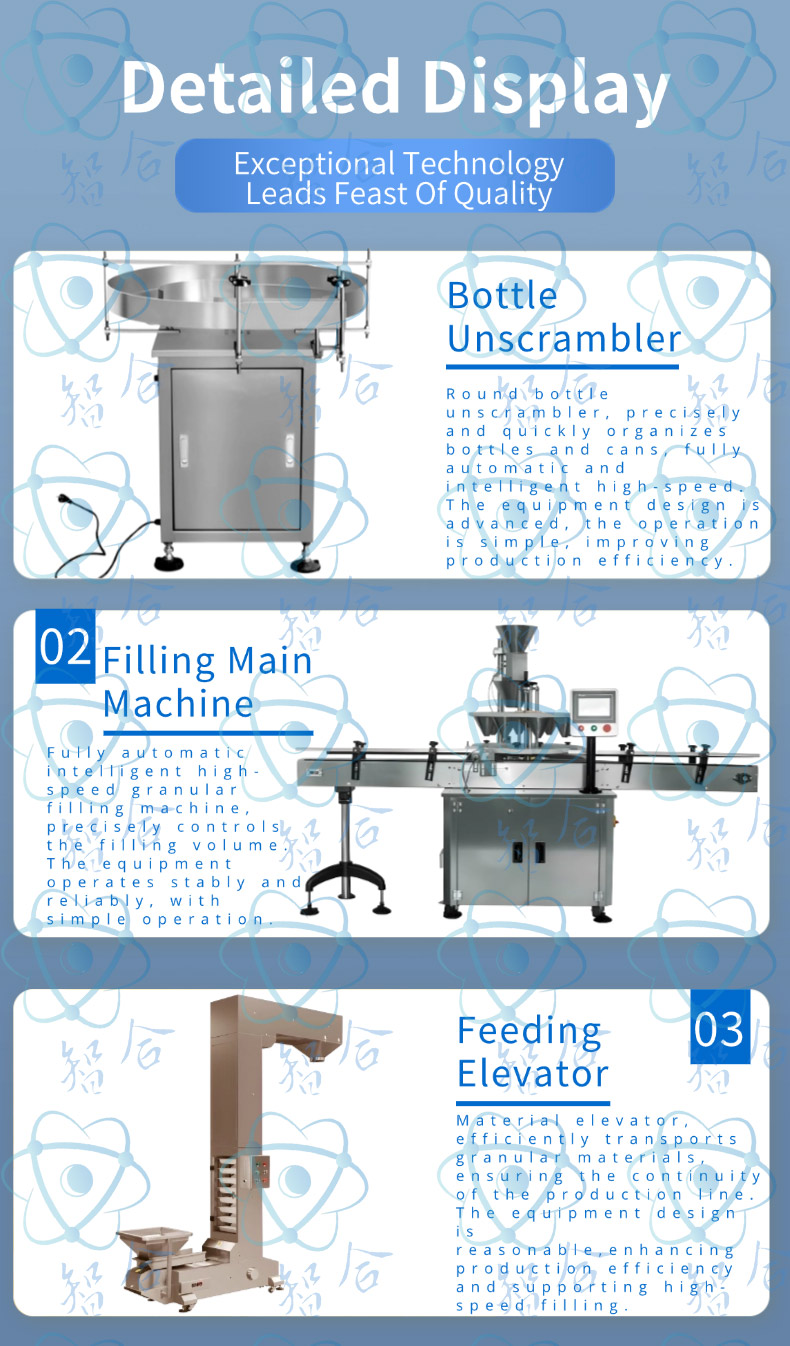

- Function: Accurately and rapidly fills particle materials into packaging containers.

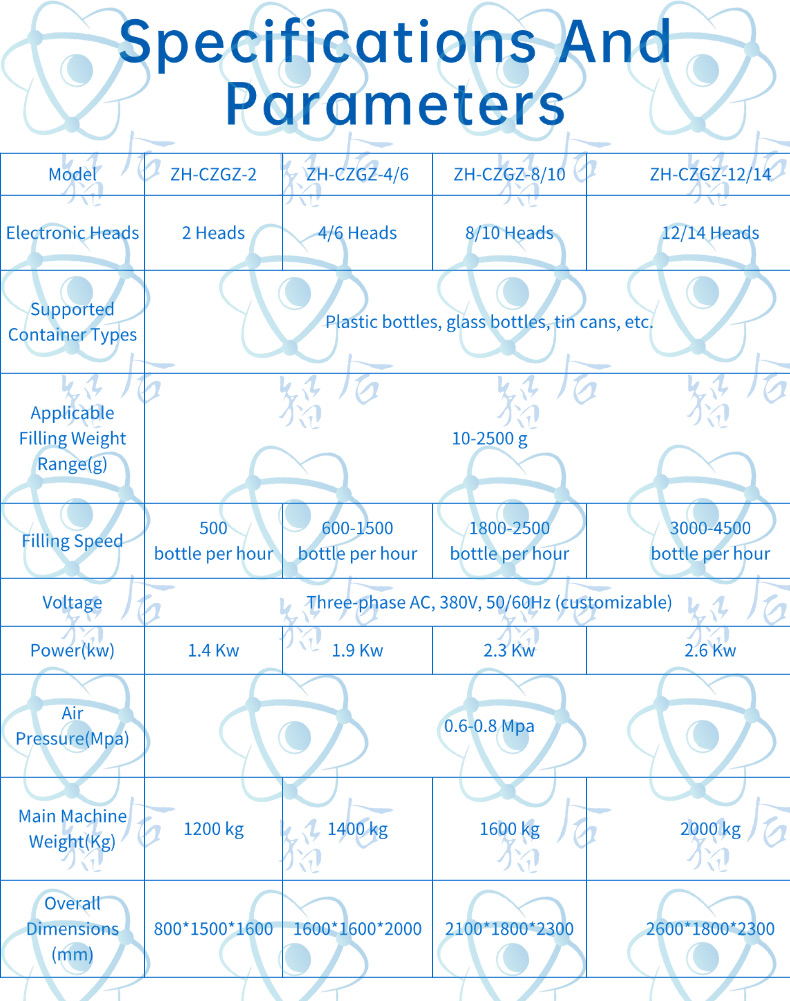

- Technical Features:

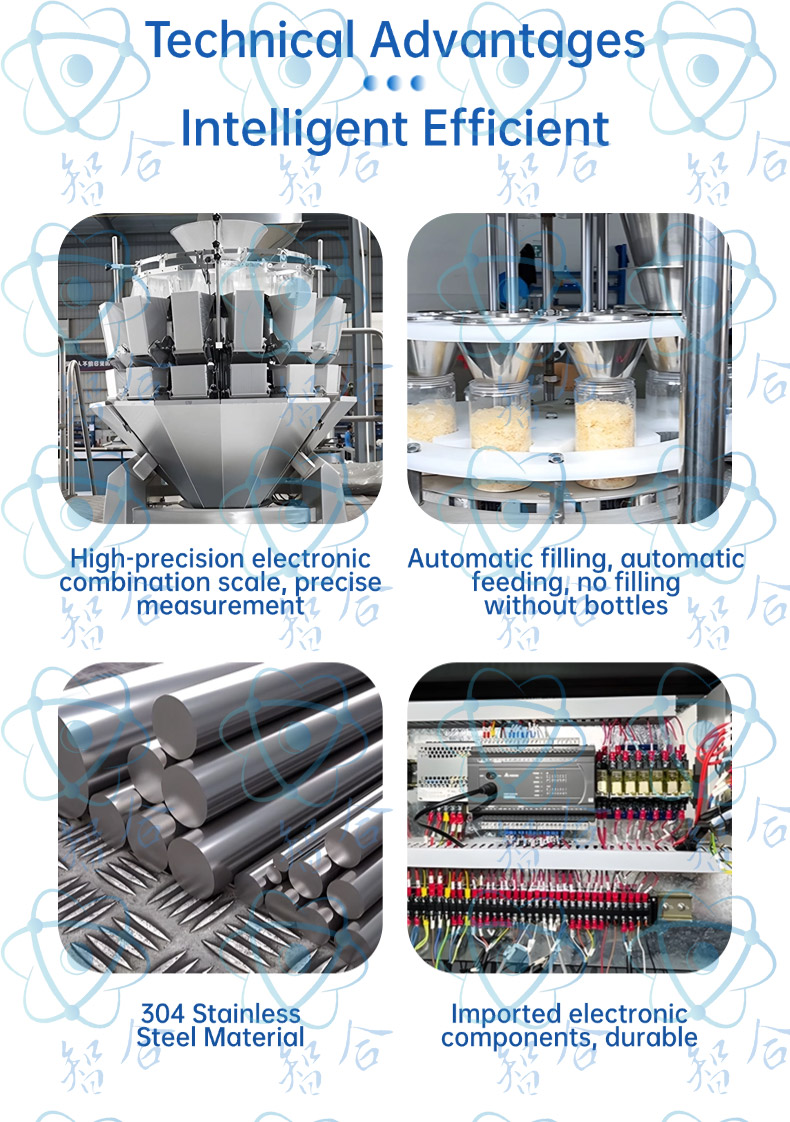

- High-precision weighing: Utilizes multi-head combination scales equipped with high-precision digital weighing sensors, ensuring precise filling through computer-optimized calculations.

- Diverse filling methods: Supports gravity filling and other methods to accommodate different material properties.

- Filling speed: Can reach 50-60 bottles/minute (specific speed depends on material and container specifications), meeting high-speed production requirements.

- Capping and Sealing System

- Function: After filling, seals and caps packaging containers to ensure product sealability and safety.

- Equipment: Includes capping machines, aluminum foil sealing machines, automatic carton sealing machines, etc., controlled by PLC for automated operation.

- Intelligent Control System

- Function: Monitors the equipment’s operational status, operating parameters, output, etc., automatically adjusts equipment working conditions and parameters to ensure stability and efficiency throughout the production process.

- Features:

- Human-machine interface (HMI): Equipped with a 7-inch or larger color touchscreen for user-friendly and straightforward operation.

- PLC control: Uses renowned PLCs such as Siemens from Germany to ensure control accuracy and stability.

- Real-time monitoring: Displays product weight trend curves, monitors equipment status in real-time, and feeds data back online to the particle packaging machine for precise control.

II. Main Equipment

- Multi-head Combination Scale

- Configuration: Dual-core ARM11 high-speed and high-performance microcontroller, high-speed and high-precision weighing sensors, dedicated stepper motor drive modules, etc.

- Accuracy: Achieves ultra-high precision (e.g., one in ten thousand), ensuring accuracy in every filling operation.

- Capping Machine

- Types: Air grip capping machines or grip-and-rotate capping machines, suitable for different sizes and shapes of bottles.

- Speed: Can reach 50-60 bottles/minute, ensuring efficient capping.

- Labeling Machine

- Types: Includes double-belt round bottle labeling machines, top labeling machines, etc., selectable based on requirements.

- Function: Applies labels to bottle bodies or caps, enhancing product aesthetics and information identification.

- Other Auxiliary Equipment

- Automatic Case Packer: Realizes automatic case opening, packing, and sealing functions.

- Inkjet Printer: Prints production dates, batch numbers, and other information on product packaging.

III. Advantages and Applications

Advantages:

- Increased Production Efficiency: Automated production processes significantly boost production speed, reduce manual intervention, and lower human error rates.

- Enhanced Product Quality: Precision weighing and efficient filling ensure product consistency and high quality.

- Strong Stability: Automated production eliminates the influence of human factors on the production process, providing a more stable production environment.

Applications:

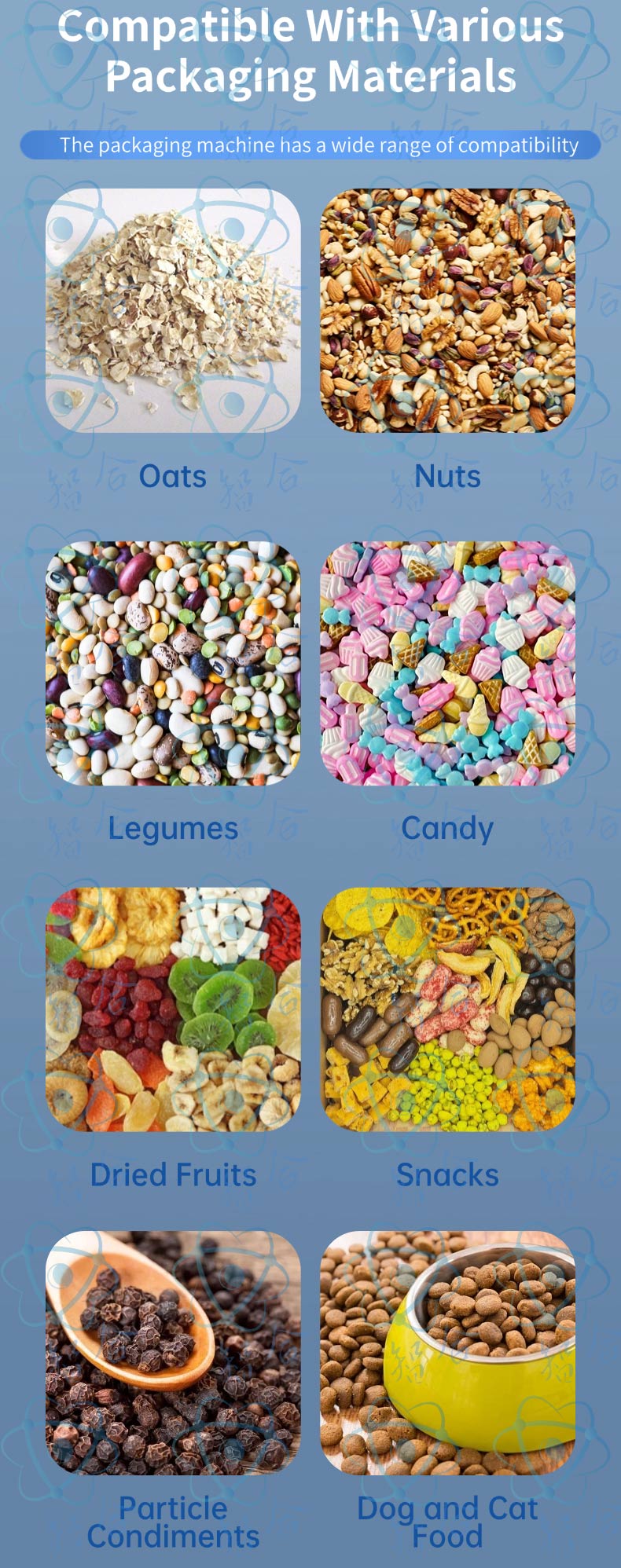

- Food Industry: Filling of granular materials such as seasoned salt, spices, and seasonings.

- Pharmaceutical Industry: Accurate weighing and packaging of granules and tablets.

- Daily Chemicals Industry: Filling of granular products like cosmetics and skincare products.

- Agriculture Industry: Packaging of granular materials such as seeds, pesticides, and feed.

In summary, the fully automated intelligent high-speed particle weighing and filling production line, with its efficiency, precision, and stability, has found widespread application across multiple industries, bringing significant economic benefits and competitive advantages to enterprises.