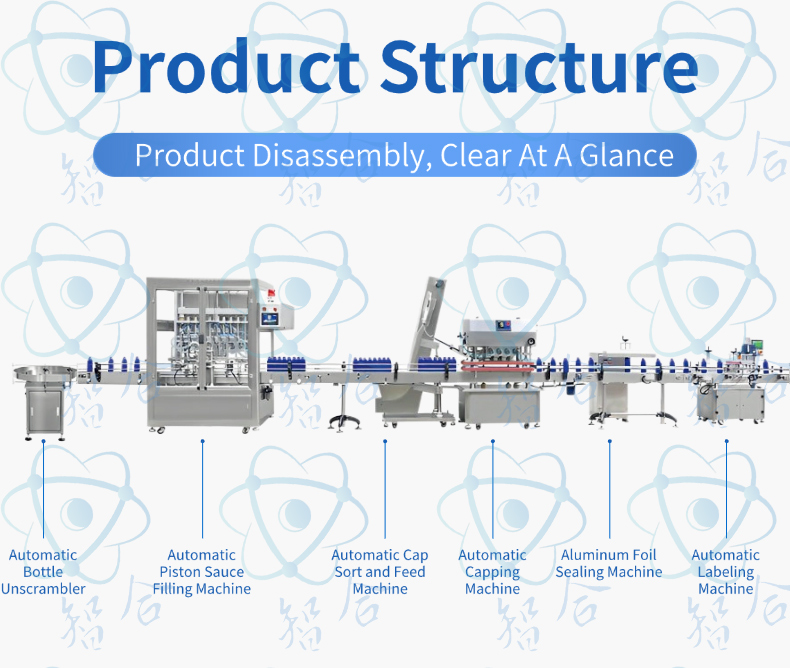

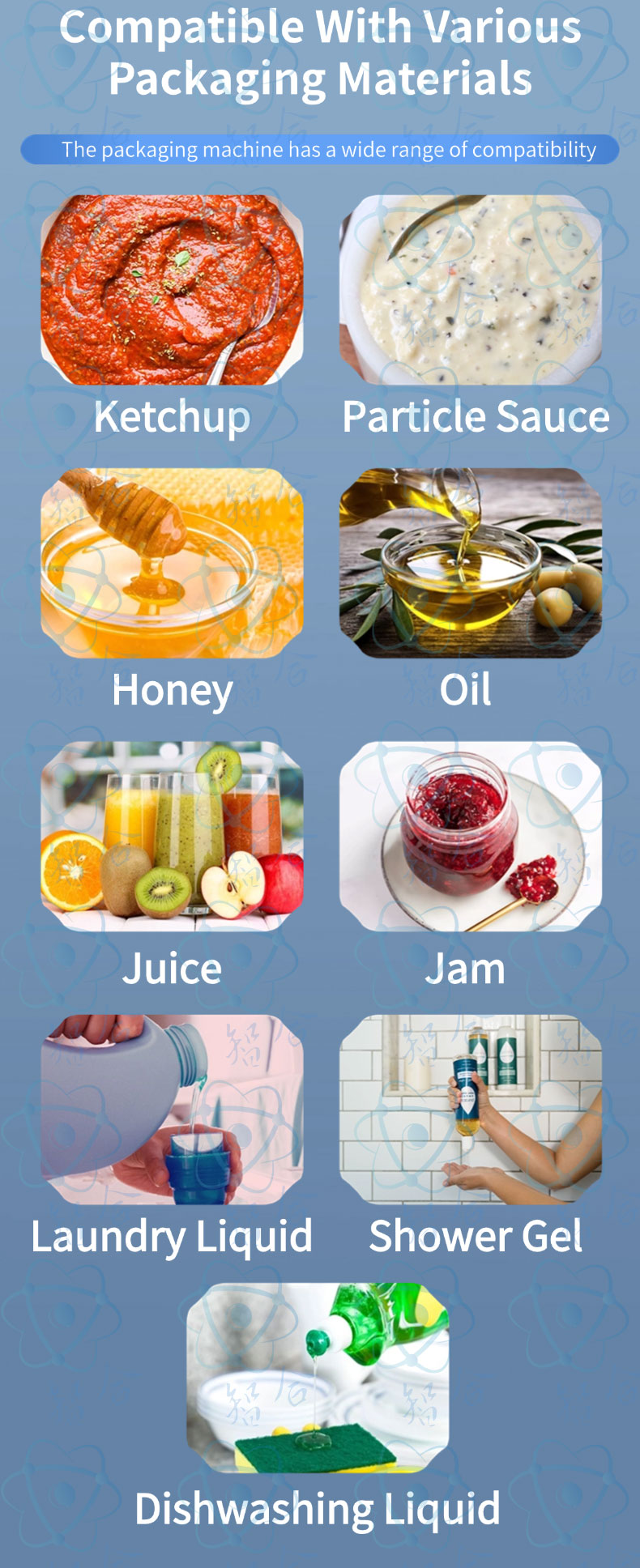

The fully automatic linear sauce filling production line is a highly integrated and automated production line specifically designed for efficient and hygienic handling of sauce filling tasks. Every step of the production line, from the preprocessing of raw material bottles to the final packaging of finished products, has achieved intelligent operation, significantly enhancing production efficiency and product quality. Here is a detailed description of the production line:

The fully automatic linear sauce filling production line is a highly integrated and automated production line specifically designed for efficient and hygienic handling of sauce filling tasks. Every step of the production line, from the preprocessing of raw material bottles to the final packaging of finished products, has achieved intelligent operation, significantly enhancing production efficiency and product quality. Here is a detailed description of the production line:

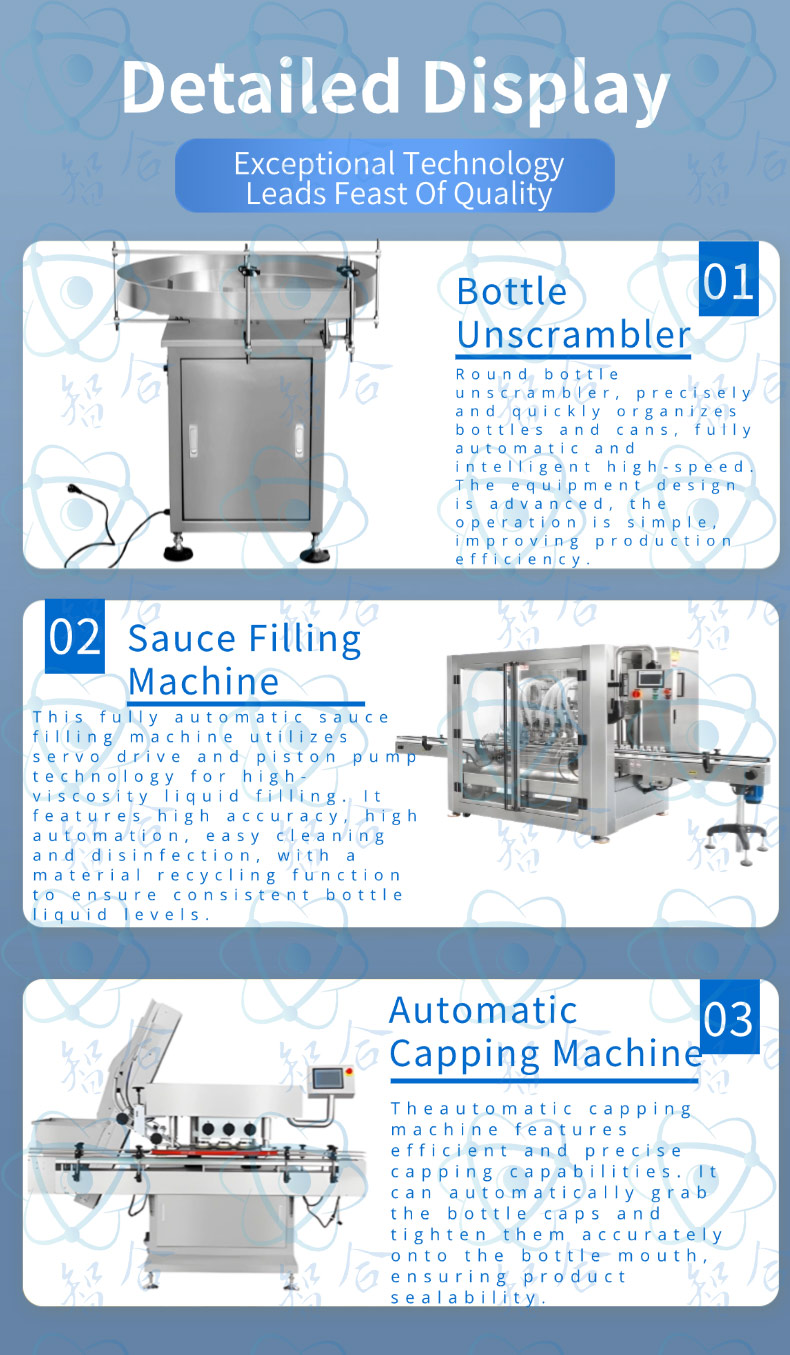

- Automatic Bottle Sorting Machine

At the beginning of the production line, an automatic bottle sorting machine is equipped. This machine utilizes devices such as vibrating disks, conveyor belts, and robotic arms to automatically arrange disorganized glass bottles (or other material containers) neatly and send them to subsequent processes. The sorting machine ensures that each bottle enters the next stage with the correct orientation and spacing, laying a solid foundation for subsequent efficient processing. - Internal and External Water/Air Bottle Washer

Next comes the internal and external water/air bottle washer, which employs high-pressure water jets or gases (like compressed air) to thoroughly clean the inside and outside of the bottles, effectively removing dust, oil, and microbial residues. Some high-end models are also equipped with disinfectant spraying systems, further enhancing cleaning and disinfection effects to ensure that bottles meet hygiene standards before filling. - Glass Bottle High-Temperature Drying and Sterilization Machine

After cleaning, bottles enter the high-temperature drying and sterilization machine. This machine utilizes hot air circulation or far-infrared heating technology to quickly remove moisture from the bottles while killing any residual microorganisms with high temperatures, ensuring the bottles’ sterile state and providing a safe environment for sauce filling. - Automatic Sauce Feeding Machine

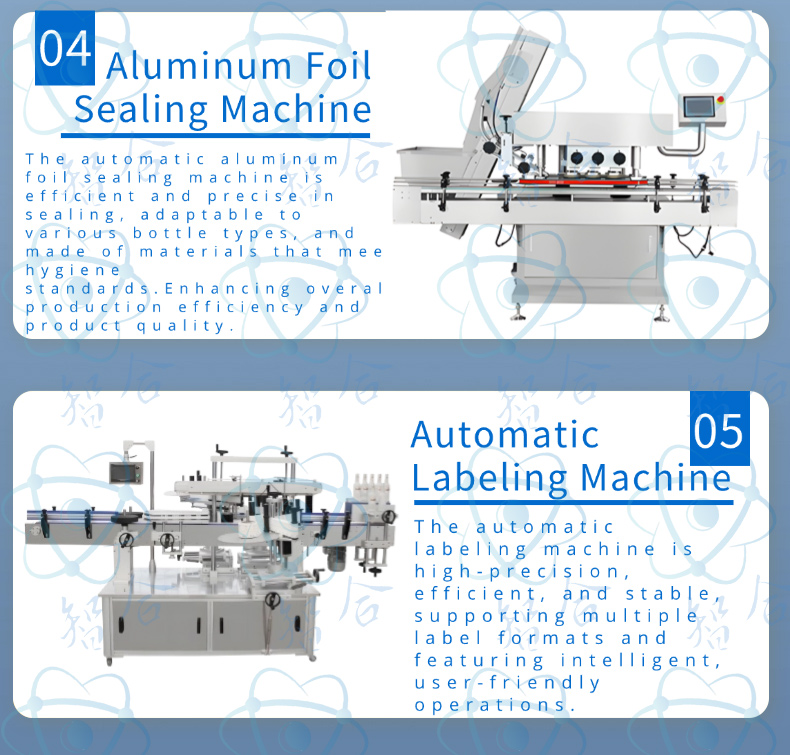

The automatic sauce feeding machine is responsible for accurately and steadily conveying sauce from storage tanks or barrels to the filling machine. Equipped with precise metering systems and conveying mechanisms, this machine ensures that the sauce remains uncontaminated during transportation and that the flow rate is stable and controllable. - Fully Automatic Multi-Head Filling Machine

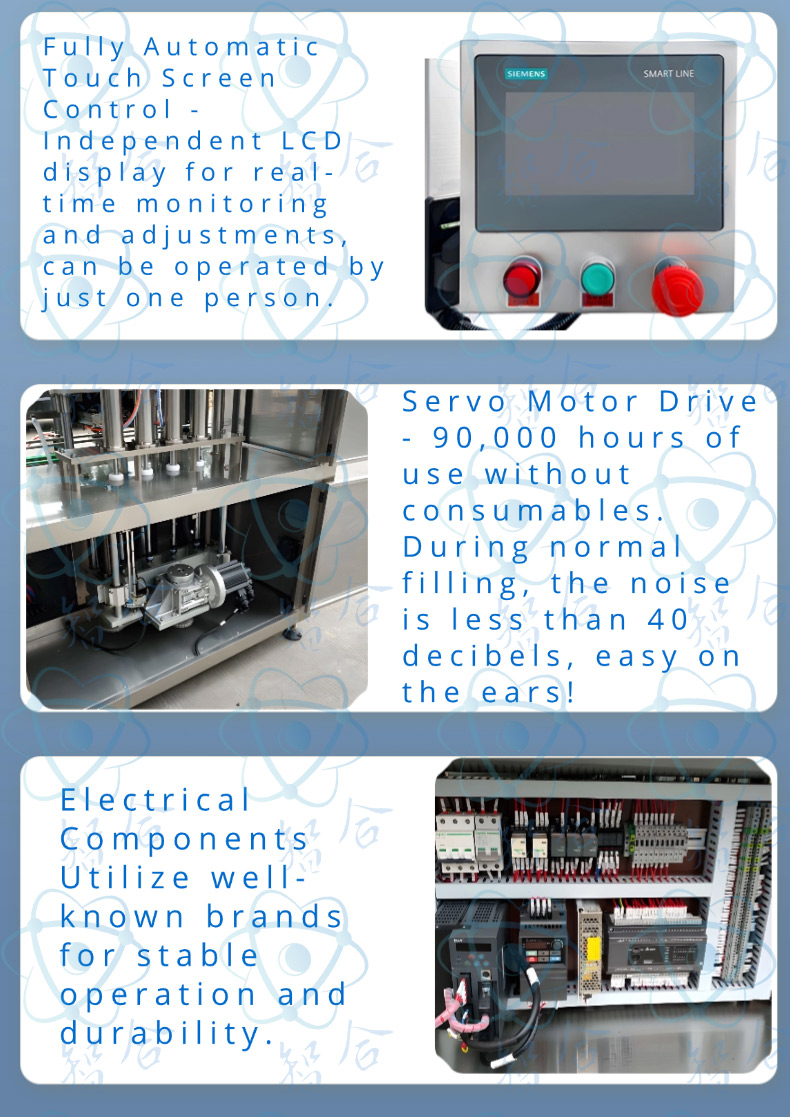

The core equipment is the fully automatic multi-head filling machine, which is equipped with multiple filling heads capable of simultaneously filling multiple bottles, significantly improving filling efficiency. The filling machine utilizes high-precision sensors and control systems to precisely control the filling volume of each bottle, ensuring consistent product specifications. - Fully Automatic Cap Sorting and Capping Machines

After filling, bottles enter the fully automatic cap sorting machine, which automatically organizes caps and feeds them one by one into the capping machine. The capping machine then tightly screws the caps onto the bottle necks using mechanical arms or rotating heads, ensuring sealing performance and preventing sauce leakage. - Fully Automatic Labeling and Inkjet Printing Machines

Subsequently, bottles enter the fully automatic labeling machine, which automatically affixes pre-printed labels to designated positions on the bottles, enhancing product aesthetics and traceability. Following this, the fully automatic inkjet printing machine prints production dates, batch numbers, and other information on the bottle bodies or caps, meeting regulatory requirements and market demands. - Fully Automatic Sleeve Labeling and Shrink Wrapping Machines

Some production lines are also equipped with fully automatic sleeve labeling and shrink wrapping machines. The sleeve labeling machine applies transparent shrink film over labeled bottles, and the shrink wrapping machine then heats the film, causing it to tightly wrap around the bottle bodies, enhancing product appearance and protection. - Fully Automatic Carton Opening, Packing, and Sealing System

Packaged bottles are then conveyed to the fully automatic carton opening, packing, and sealing system, which automatically opens cartons, arranges bottles inside, and seals the cartons, forming the final product packaging. - Robotic Palletizing System

Finally, the robotic palletizing system utilizes industrial robots to transport filled cartons to designated locations and stack them according to preset arrangements, reducing manual intervention and improving warehouse efficiency.

The entire fully automatic linear sauce filling production line integrates multiple advanced technologies, achieving full automation from raw materials to finished products. This not only enhances production efficiency but also significantly improves product hygiene quality and market competitiveness.